Method for synchronously removing high-concentration ammonia nitrogen, iron and manganese in water through reverse flow oxygenation multi-stage catalytic oxidation

A catalytic oxidation and reverse flow technology, applied in the field of drinking water treatment, can solve problems such as insufficient dissolved oxygen, and achieve the effects of improving catalytic oxidation efficiency and water treatment capacity, less engineering investment, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

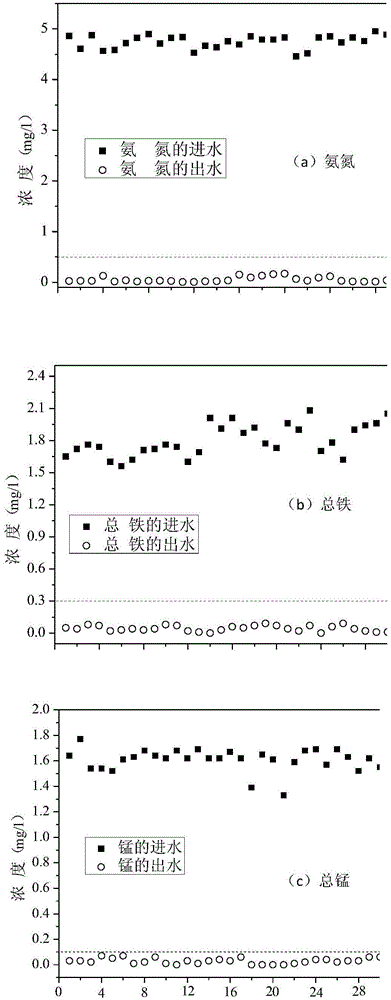

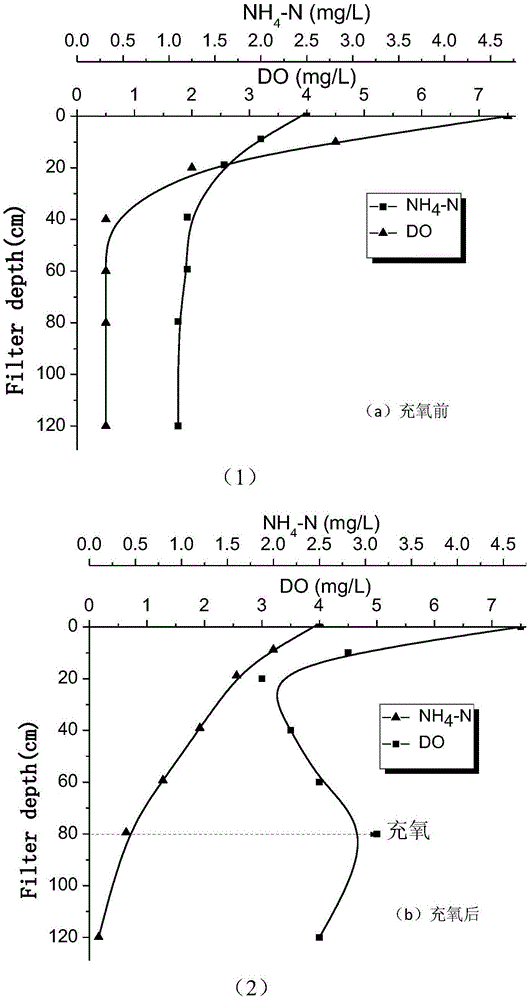

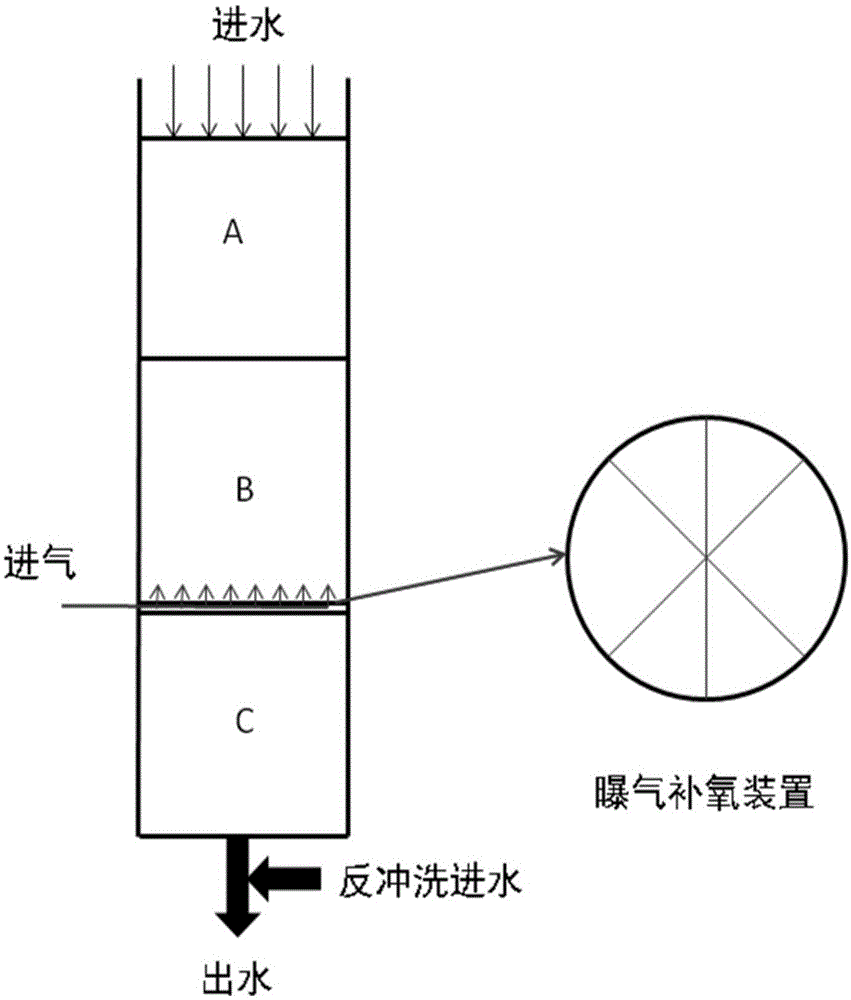

[0049] Embodiment: The inventor carried out a pilot test based on the above-mentioned catalytic oxidation removal system of ammonia nitrogen in raw water. The raw water of the pilot test used the filter tank effluent of a surface water plant in Northwest China, and the designed water intake was 1m 3 / h, the design filtration rate is 6m / h, the filter material layer of the filter column is made of homogeneous quartz sand, the equivalent particle size is 1.20mm, and the unevenness coefficient K 80 = 1.38, the thickness of the filter material layer is 1.2m; the concentration of Fe salt is 1.4mg / L, the concentration of Mn salt is 2mg / L; the soluble inorganic salt is Na 2 HPO 4 , the dosing concentration is 30μg / L; the auxiliary oxidant is potassium permanganate, and the dosing concentration is 4.8mg / L. After 30 days of operation, 3 mg / L of ammonia nitrogen was added to the raw water, and the ammonia nitrogen in the effluent was always kept below 0.3 mg / L after the preparation of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com