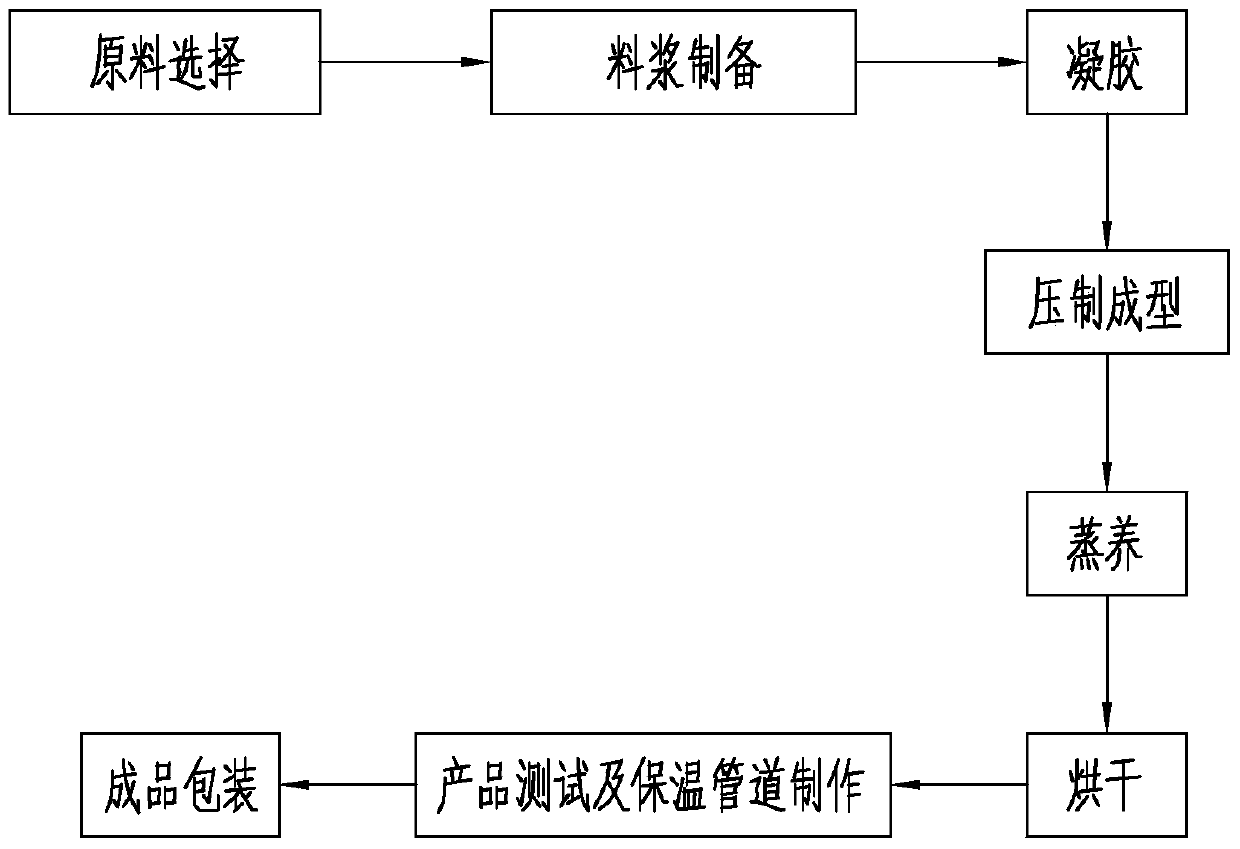

A method for preparing ultra-light pipe insulation material

A pipe insulation and ultra-light technology, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of not achieving the best insulation effect, reducing the appearance quality of products, and the pipeline connection is not dense, etc., to achieve Improve appearance quality, good mold release effect, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

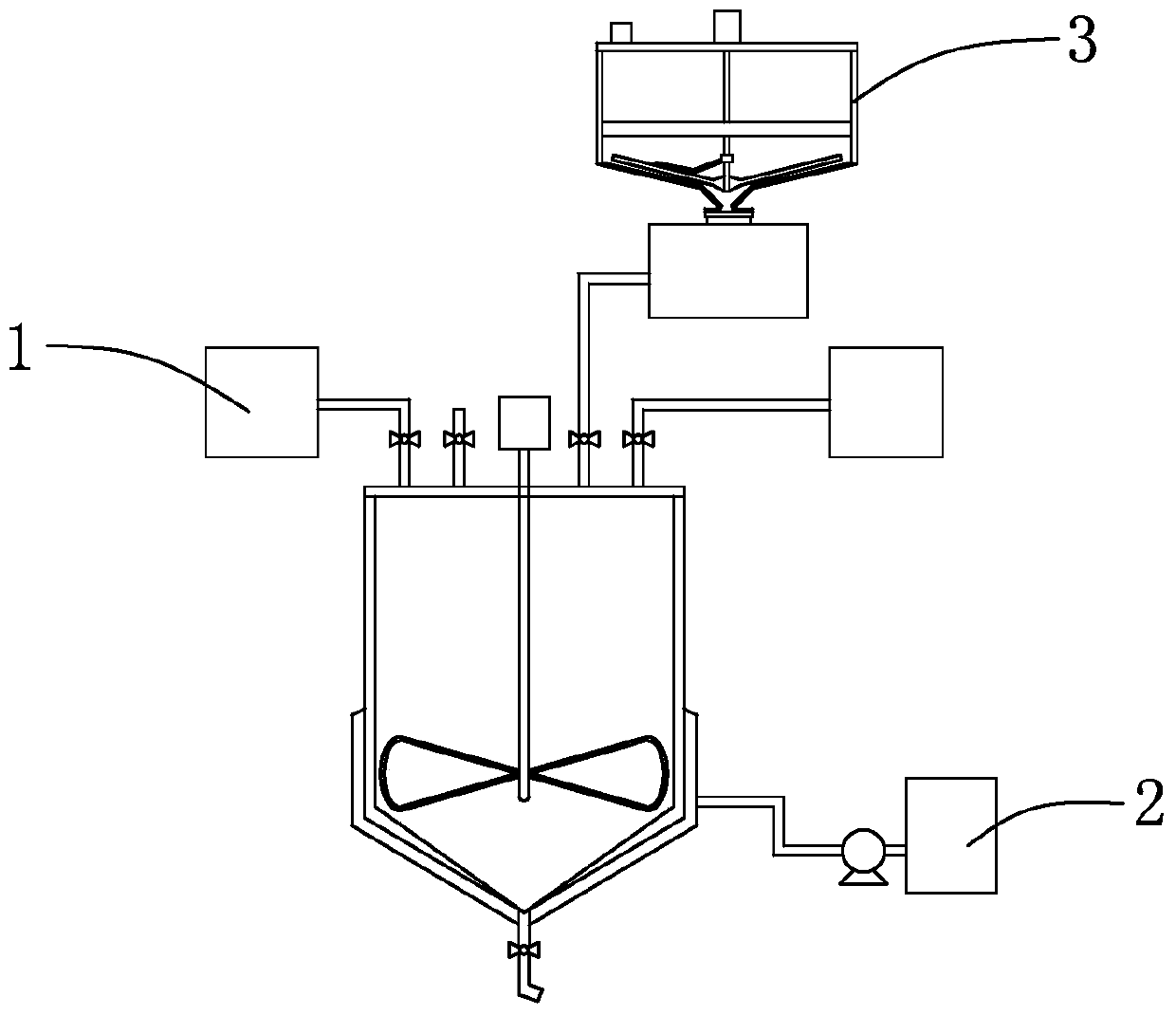

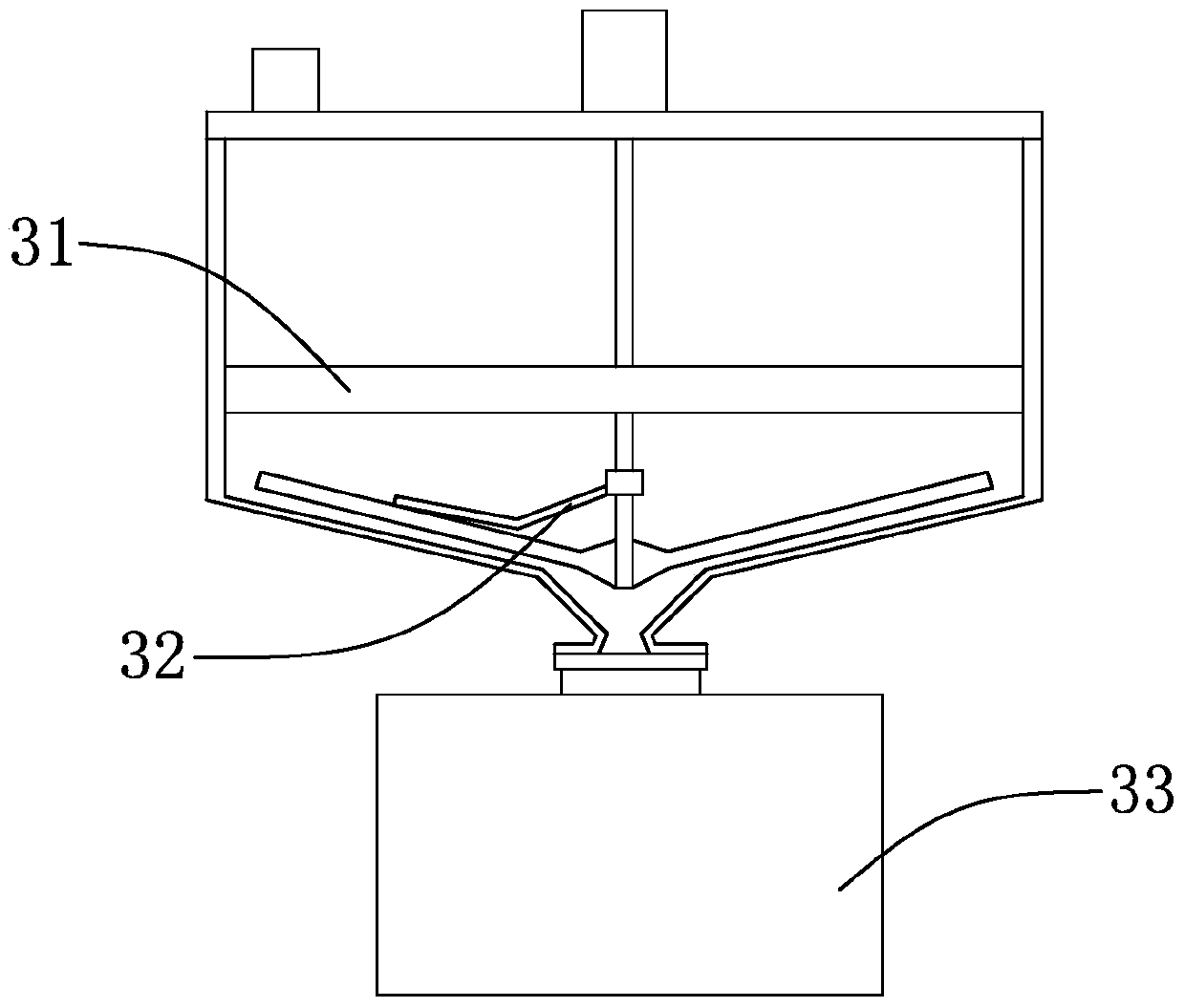

Method used

Image

Examples

Embodiment Construction

[0030]An ultra-light pipe insulation material, its raw material composition includes siliceous material, calcareous material, water, red mud, admixture, bentonite, reinforcing fiber and fiber dispersant, the siliceous material is made of quartz powder, the calcareous material is made of quicklime, The reinforcing fiber is a mixed fiber of glass fiber and wood fiber, and the admixture is generally Sr(OH) 2 , one or more of water glass and hard calcium silicate seeds.

[0031] The siliceous material of the present invention uses quartz powder, mainly because the inside of the quartz spherical particles is dense, the surface of the particles is relatively smooth, and it is easy to disperse during the dynamic reaction process. According to the theory of spatial geometric packing, these smooth spherical particles are very easy to form a compact mosaic structure, so that the product has high mechanical strength. In the dynamic reaction, the finer the quartz powder, the higher the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com