Polymeric chain of one-dimensional nanoparticle and preparation method thereof

A nanoparticle and polymer chain technology, applied in the field of nanomaterial modification, can solve the problems of uneven distribution of polymer linear polymer chain length, poor stability, low flexibility, etc., to achieve multi-functional integration and the development and stability of new functions. Improved performance, uniform and controllable spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also discloses a method for preparing the above one-dimensional nanoparticle polymer chain, which includes the following steps,

[0059] 1) Chemical modification of the surface of nanoparticle A: Graft polymer P on the surface of nanoparticle A, control the number and length of polymer chain segments, and introduce active functional groups -N at the end of the polymer 3 , to obtain nanoparticles A-P-N with surface-grafted terminal azido-based polymers 3 .

[0060] This step 1) specifically includes three small steps, specifically:

[0061] 1-1) Immobilized ATRP initiator: the powder of nanoparticle A is vacuum-dried at 60-90°C, ground, added with a solvent and quickly sheared to disperse to obtain a suspension of nanoparticle A, then add triethylamine and 2- Bromoisobutyryl bromide, ultrasonic dispersion treatment, sealed tube reaction, first stirred and reacted at 0-3°C for 24-36 hours, continued to stir and reacted at 20-25°C for 0-12 hours, th...

Embodiment 1

[0085] Titanium dioxide nanoparticles in this example, with an average particle size of 10 nm and a purity greater than 99.8%, were purchased from Nanjing Epurui Nano Materials Co., Ltd. Other reagents were purchased from Aladdin Chemical Co., Ltd., and some reagents were purified before use.

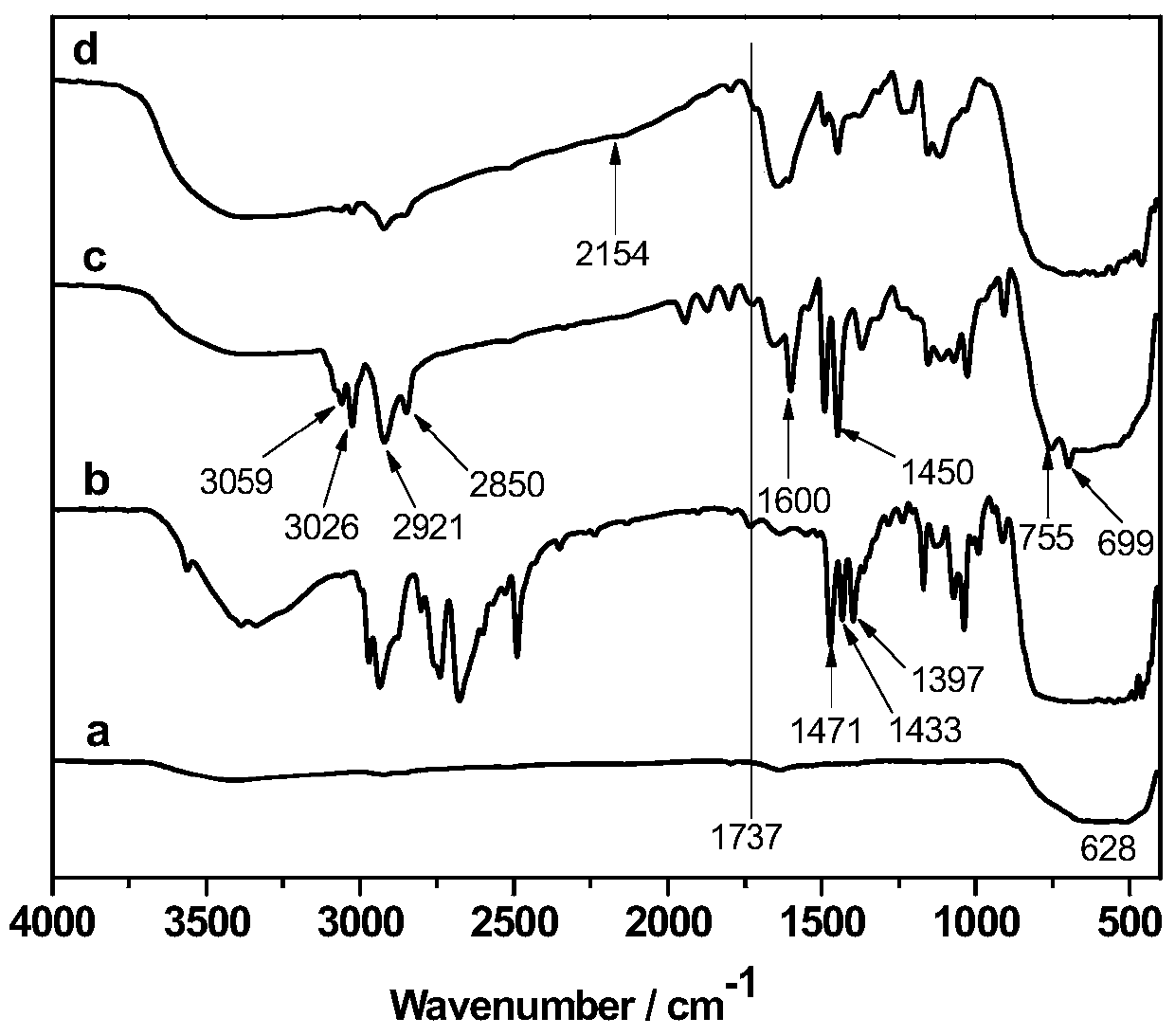

[0086] In this example, a one-dimensional nano-titanium oxide polystyrene chain shown in the following formula I-1-1 was prepared.

[0087]

[0088] Specific steps are as follows:

[0089] Step 1) Nano TiO 2 Surface graft polymerized styrene

[0090] The synthetic route of this step is shown below,

[0091]

[0092] 1-1) Nano-TiO 2 surface mounted initiator

[0093] Weigh TiO 2 Nanoparticles, vacuum dried at 80°C for 24 hours, cooled to room temperature, ground for 5 minutes with a mortar, added anhydrous tetrahydrofuran and quickly sheared and dispersed for 10 minutes to obtain TiO 2 Suspension of nanoparticles; transferred to a polymerization tube, ultrasonically disperse...

Embodiment 2

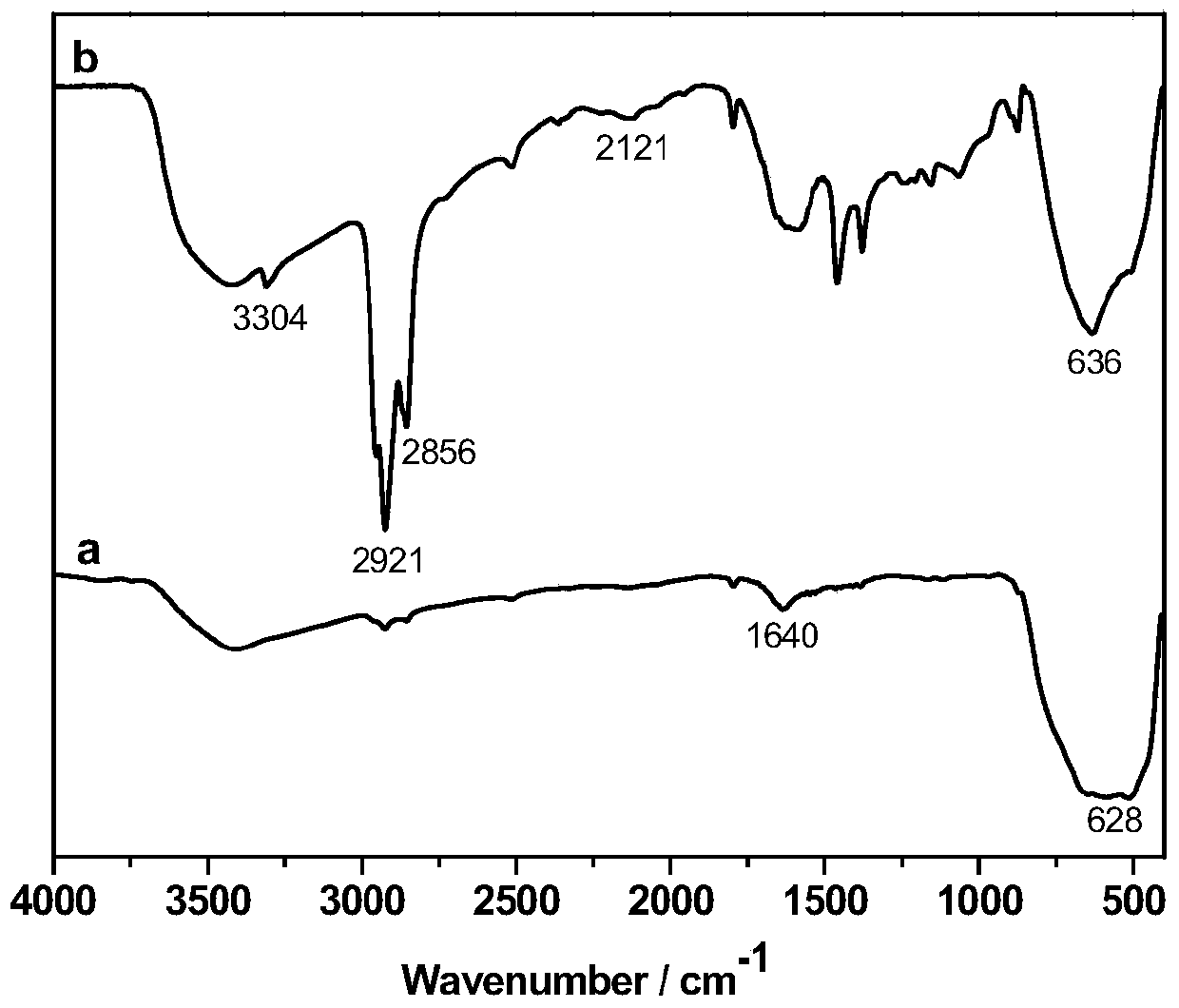

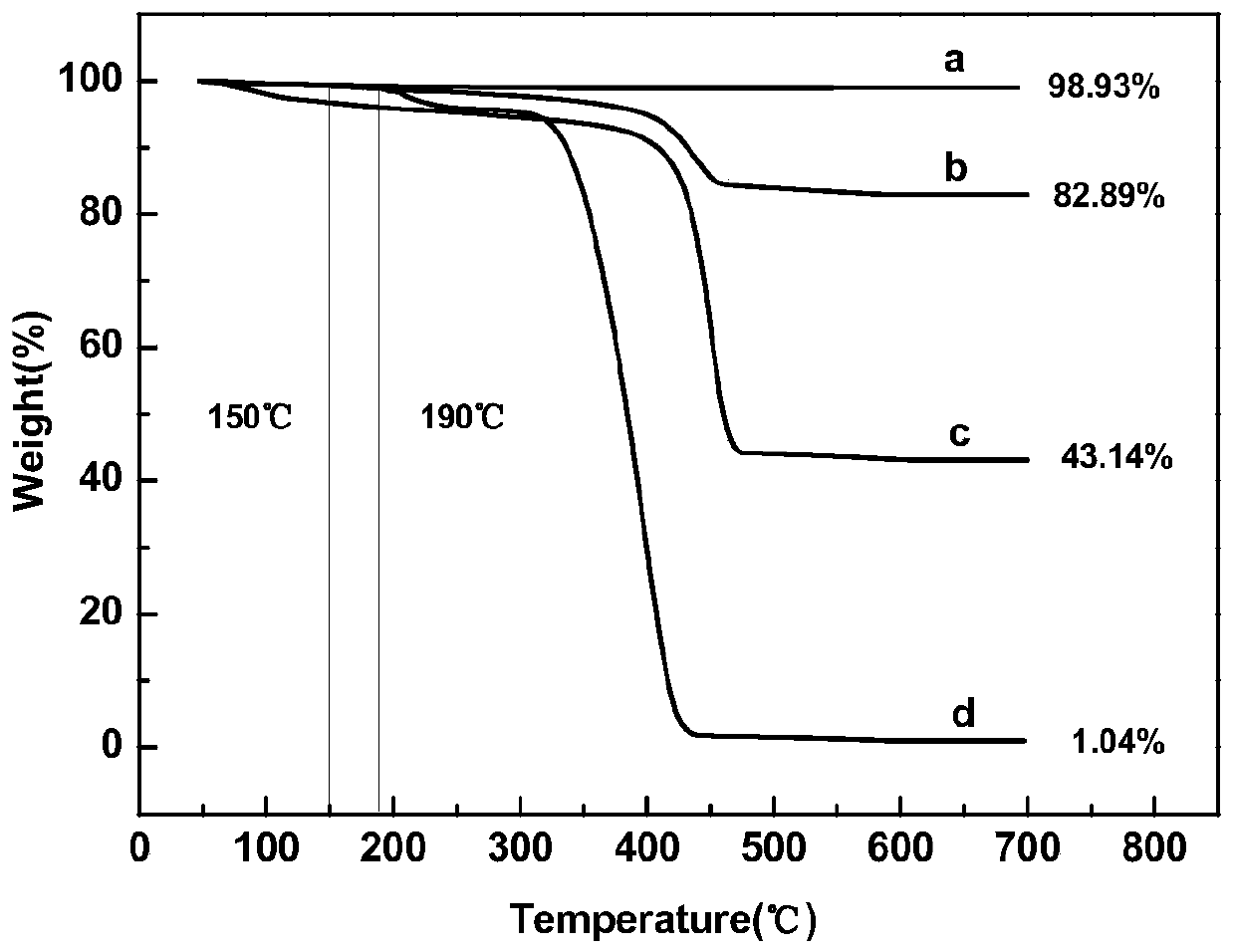

[0117] The zinc oxide nanoparticles in this example have an average particle size of 15nm and a purity greater than 99.99%, and ferric oxide nanoparticles have an average particle size of 20nm and a purity greater than 99.99%, both of which were purchased from Nanjing Epurui Nano Materials Co., Ltd. Other reagents were purchased from Aladdin Chemical Co., Ltd., and some reagents were purified before use.

[0118] As a molecule of ZnO nanoparticles, according to the calculation formula 1, the molar mass of ZnO nanoparticles is about 5.954×10 6 g / mol; a Fe 3 o 4 Nanoparticles as a molecule, according to formula 1, get Fe 3 o 4 The molar mass of nanoparticles is about 1.306×10 7 g / mol; due to the molecular weight of 2-bromoisobutyryl bromide, bromopropyne and surface graft polymerized PS, the order of magnitude is far less than 10 6 , so the molar masses of ZnO-Br nanoparticles and ZnO-PS-Br nanoparticles are both about 5.954×10 6 g / mol, Fe 3 o 4 The molar mass of -C≡CH n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com