A modified acrylic resin energy-saving and environmental protection coating for metal boxes of product packaging

A technology of acrylic resin and product packaging, applied in the direction of anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve problems such as unfavorable human health, pollute the environment, waste coatings, etc., achieve good environmental protection effects, reduce VOCs, and ensure quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

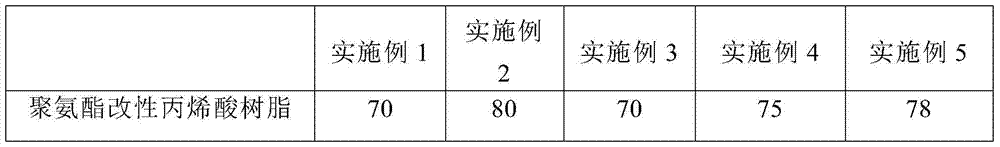

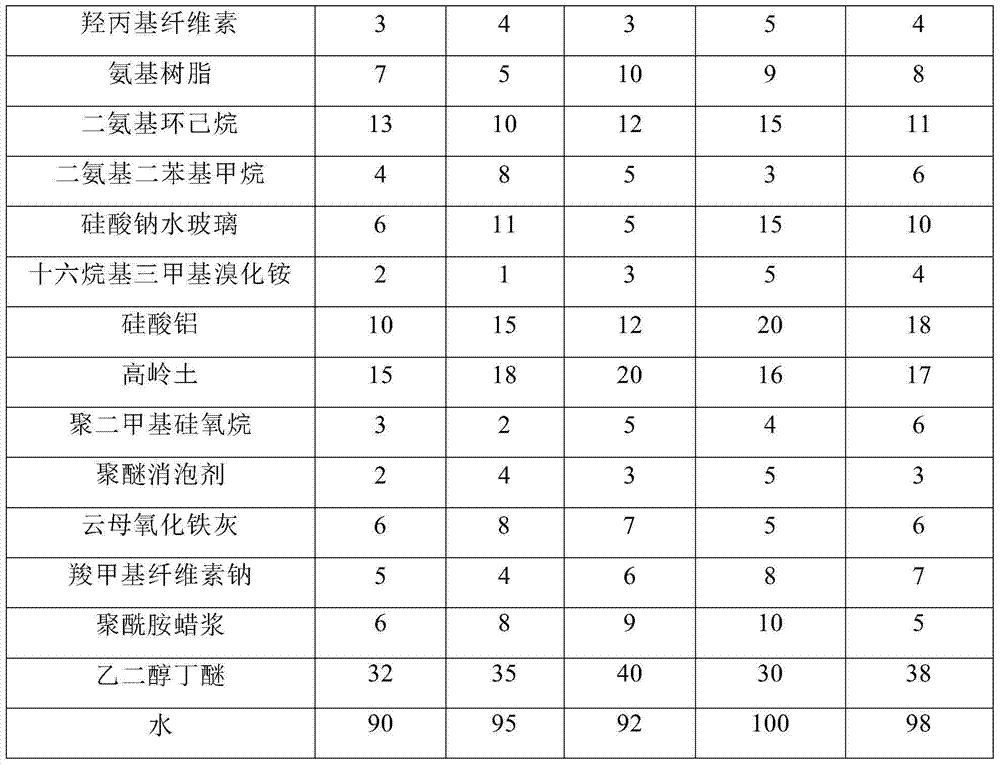

[0031] The present invention will be further described below through specific examples, but the examples do not limit the protection scope of the present invention.

[0032]Table 1 is a list of mass fractions of components of a modified acrylic resin energy-saving and environment-friendly coating for a product packaging metal box described in an embodiment of the present invention. Table 2 is a list of components for preparing polyurethane-modified acrylic resin described in the examples of the present invention. Table 3 is a list of performance parameters of a modified acrylic resin energy-saving and environment-friendly coating for a product packaging metal box described in the embodiment of the present invention. Table 4 is a list of coating performance parameters after a modified acrylic resin energy-saving and environment-friendly coating for a product packaging metal box described in the embodiment of the present invention is rolled on the surface of the product packagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com