Deburring method for joint accessories

A technology for sewing parts and deburring, which is applied in the field of deburring and sewing parts deburring, and can solve problems such as polluting the environment, ineffective effects, and damaging the health of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

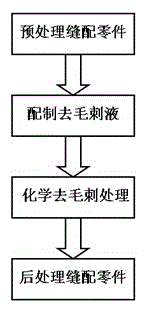

Image

Examples

Embodiment 1

[0019] The specific processing method is as follows:

[0020] a) Pretreatment of sewing parts, the specific treatment process is: first prepare an alkaline cleaning solution, which is prepared from the following ingredients by weight percentage: sodium phosphate 8%, sodium dihydrogen phosphate 2%, sodium silicate 5%, 1% sodium alkylbenzene sulfonate, 84% water; then put the sewing parts into the alkaline cleaning solution, stir the cleaning solution slightly at a stirring speed of 10 times / min for 3 minutes, and fully remove the grease on the surface of the sewing parts ; Then take out the sewing parts from the alkaline cleaning solution, wash the cleaning solution on the sewing parts with clean water; finally dry the sewing parts with a dryer at a temperature of 40 °C.

[0021] b) To prepare deburring solution, weigh 40% hydrogen peroxide, 36% citric acid, 20% malonic acid, 3% sulfuric acid, and 1% combined additives by weight percentage, and put them into a ceramic container...

Embodiment 2

[0025] The specific processing method is as follows:

[0026] a) Pretreatment of sewing parts, the specific treatment process is: first prepare an alkaline cleaning solution, which is prepared from the following ingredients by weight percentage: sodium phosphate 8%, sodium dihydrogen phosphate 2%, sodium silicate 5%, 1% sodium alkylbenzene sulfonate, 84% water; then put the sewing parts into the alkaline cleaning solution, stir the cleaning solution slightly at a stirring speed of 10 times / min for 3 minutes, and fully remove the grease on the surface of the sewing parts ; Then take out the sewing parts from the alkaline cleaning solution, wash the cleaning solution on the sewing parts with clean water; finally dry the sewing parts with a dryer at a temperature of 40 °C.

[0027] b) To prepare the deburring solution, weigh 33% hydrogen peroxide, 38% citric acid, 22% malonic acid, 5% sulfuric acid, and 2% combined additives by weight, and put them into a ceramic container Stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com