A kind of helical gan single crystal nanowire and its preparation method

A single-crystal nano-spiral technology, applied in the directions of single-crystal growth, nanotechnology, single-crystal growth, etc., can solve the problem of not involving zigzag nanowires, and achieve easy promotion, good uniformity, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

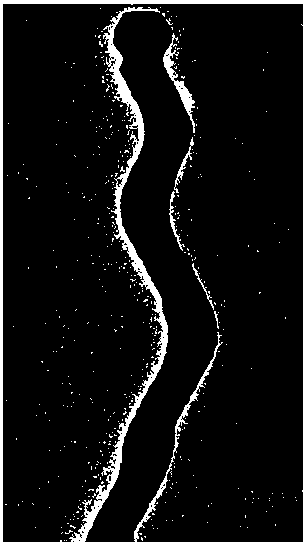

Image

Examples

Embodiment 1

[0020] Example 1 A method for preparing helical GaN nanowires is achieved through the following process: using chemical vapor deposition to prepare helical GaN nanowires, using metal Ga and NH 3 Gas is used as Ga source and N source respectively, MoCl 5 The powder is used as the Mo source, and an appropriate amount of metal Ga is weighed and placed in a ceramic boat, which is placed in the middle of the horizontal tube furnace, and an appropriate amount of MoCl is weighed according to the molar ratio Mo / Ga=0.16 5 Put it in a ceramic boat, place it at an upstream position 20-30cm away from the central temperature zone, and place a gold-plated Si substrate at a position 20-25cm away from the central temperature zone, and seal the horizontal tube furnace; start the vacuum system, Vacuum in the furnace to 1×10 -3 Pa; feed Ar gas, when heated to 970 degrees Celsius, adjust the Ar gas to 10 sccm, and simultaneously turn on the ammonia gas flow valve to feed in at a flow rate of 30...

Embodiment 2

[0023] Example 2 Preparation of helical GaN nanowires. The system used consists of a horizontal tube furnace heated by silicon molybdenum rods, a gas system and a vacuum system. GaN helical nanowires are prepared by chemical vapor deposition, using metal Ga and NH 3 Gas is used as Ga source and N source respectively, MoCl 5 Powder as Mo source;

[0024] (1) Weigh metal Ga and place it in a ceramic boat, place it in the middle of the horizontal tube furnace, weigh MoCl according to the molar ratio Mo / Ga=0.15 5 The powder is placed in a ceramic boat, placed 20-30cm upstream from the central temperature zone, and a gold-plated Si substrate is placed 20-25cm downstream from the central temperature zone to seal the horizontal tube furnace;

[0025] (2) Start the vacuum system, and the vacuum in the furnace reaches 1×10 -3 At Pa, feed Ar gas with an Ar gas flow rate of 10 sccm, heat to 940°C, and keep it warm for 2 hours. At the same time, turn on the ammonia gas flow valve and f...

Embodiment 3

[0026] Example 3 Preparation of helical GaN nanowires. The system used consists of a horizontal tube furnace heated by silicon molybdenum rods, a gas system and a vacuum system. GaN helical nanowires are prepared by chemical vapor deposition, using metal Ga and NH 3 Gas is used as Ga source and N source respectively, MoCl 5 Powder as Mo source;

[0027] (1) Weigh metal Ga and put it in a ceramic boat, place it in the middle of the horizontal tube furnace, weigh MoCl according to the molar ratio Mo / Ga=0.20 5 The powder is placed in a ceramic boat, placed 20-30cm upstream from the central temperature zone, and a gold-plated Si substrate is placed 20-25cm downstream from the central temperature zone to seal the horizontal tube furnace;

[0028] (2) Start the vacuum system, and the vacuum in the furnace reaches 1×10 -3 At Pa, feed Ar gas with an Ar gas flow rate of 80 sccm, heat to 1050°C, and keep warm for 0.5 hours. At the same time, turn on the ammonia gas flow valve and fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com