Thermal insulation hollow glass

A heat insulation and hollow technology, applied in parallel glass structures, building components, buildings, etc., can solve the bottleneck of heat transfer coefficient, which can only reach 1.65~1.8W, and achieve excellent heat insulation performance and wide climate adaptability , The effect of reducing building energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

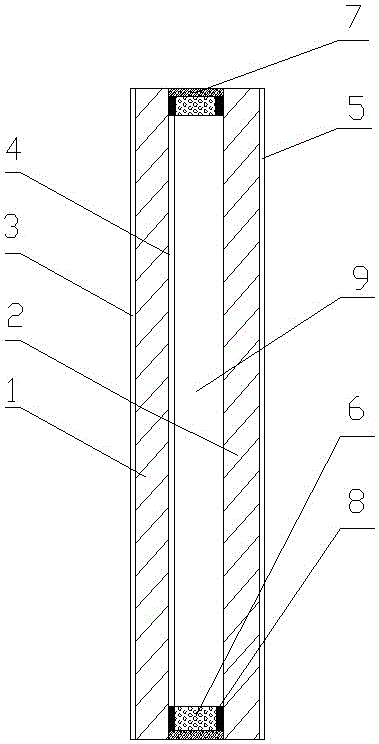

[0023] Specifically, the outer glass 1 is made of 6mm white glass, and the metal oxide film layer coated on the outer surface is an anatase nano-titanium oxide film layer 3, and the anatase-type nano-titanium oxide film layer 3 is applied by a spraying process. On the glass surface, the film thickness after sintering is 150nm. The low-emissivity coating 4 on the inner surface of the outer glass 1 is a single silver low-emissivity film layer with metallic silver as the functional layer, the inner glass 2 is made of 6mm float white glass, and the inner glass 2 is coated with a layer of thermal insulation The low-emissivity coating layer 5 is a low-emission coating layer with tin oxide as the functional film. The film surface is on the inner surface facing the indoor air surface, prepared by chemical vapor deposition coating technology, between the outer glass 1 and the inner glass 2 The hollow spacer 6 is a 12A aluminum hollow spacer filled with a molecular sieve desiccant insid...

Embodiment 2

[0026]Specifically, the outer glass 1 is made of 8mm white glass, and the metal oxide film layer coated on the outer surface is an anatase nano-titanium oxide film layer 3, and the anatase-type nano-titanium oxide film layer 3 is coated by a spraying process. On the glass surface, the film thickness after sintering is 100nm. The low-emissivity coating 4 on the inner surface of the outer glass 1 is a double-silver low-emissivity film layer with metallic silver as the functional layer. The inner glass 2 is made of 8mm float white glass, and the inner surface of the inner glass 2 is coated with a layer of thermal insulation The low-emissivity film layer 5 is a low-emission coating layer with tin oxide as the functional film, and the film surface is prepared by chemical vapor deposition coating technology on the inner surface facing the indoor air side. The hollow spacer 6 between the outer glass 1 and the inner glass 2 is a 12A aluminum hollow spacer filled with a molecular sieve...

Embodiment 3

[0030] Specifically, the outer glass 1 is made of 8mm ultra-clear glass, and the metal oxide film layer coated on the outer surface is an anatase nano-titanium oxide film layer 3, which is coated by a spraying process. Covered on the glass surface, the film thickness after sintering is 120nm. The low-emissivity coating 4 on the inner surface of the outer glass 1 is a three-silver low-emissivity film layer with metallic silver as the functional layer, the inner glass 2 is made of 8mm float white glass, and the inner surface of the inner glass 2 is coated with a layer of thermal insulation The low-emissivity film layer 5 is a low-emission coating layer with tin oxide as the functional film, and the film surface is prepared by chemical vapor deposition coating technology on the inner surface facing the indoor air side. The hollow spacer 6 between the outer glass 1 and the inner glass 2 is a 12A aluminum hollow spacer filled with a molecular sieve desiccant inside, and the hollow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com