Method for detecting low-quality starch-doped potato starch fast

A technology of potato starch and tapioca starch, which is applied in the direction of measuring devices, color/spectral characteristic measurement, instruments, etc., can solve problems such as difficult to quickly identify, damage the legitimate interests of food processing manufacturers and consumers, and disrupt market order, etc. The method is simple , rapid prediction ability and stability, and the effect of good market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the scanning determination of starch granule ultramicro morphology

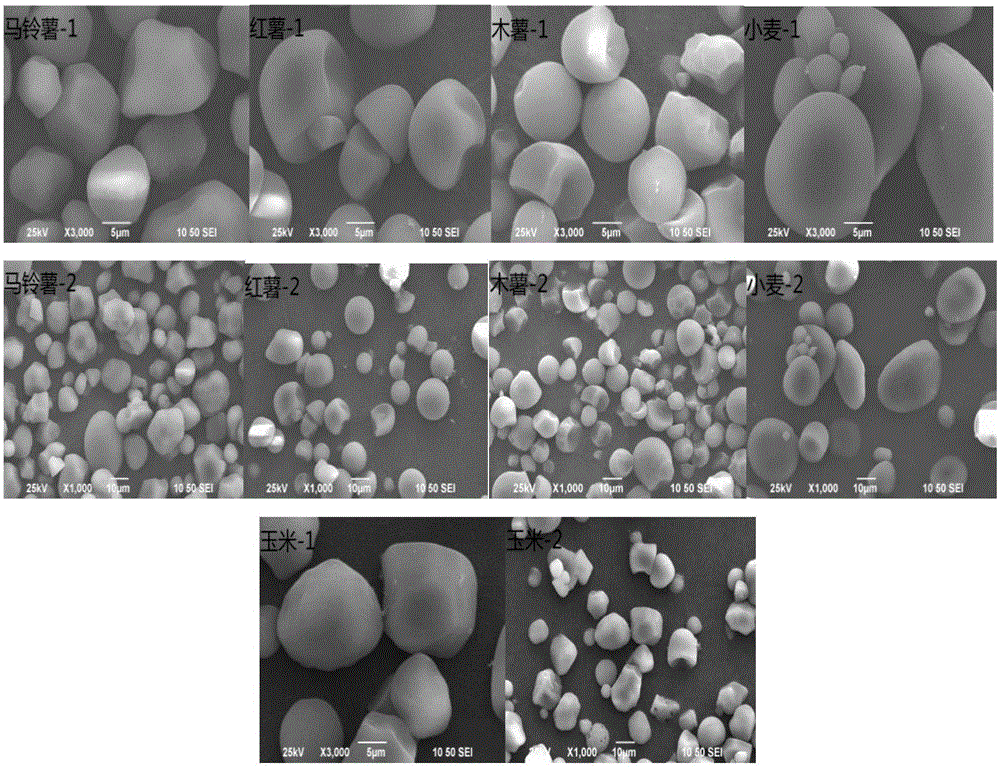

[0034] Take about 0.1g of potato starch, corn starch, sweet potato starch, wheat starch and tapioca starch samples, and sprinkle them evenly on the metal stage with conductive glue one by one. Under vacuum conditions, the conventional vacuum spraying method is used for gold spraying treatment, so that the surface is coated with a conductive film. Place it under an electron scanning microscope, adjust the magnification to scan and take pictures of the particles, wherein the magnification of potato starch, corn starch, sweet potato starch, wheat starch and tapioca starch is more ideal between 1000× and 3000×.

[0035] Test results such as figure 1 As shown, among them, the appearance of potato starch is an irregular polyhedron, sweet potato starch and tapioca starch are spherical, and wheat flour is flat; therefore, it is possible to identify whether sweet potato starch, tapioca starch is ...

Embodiment 2

[0036] Embodiment 2: the detection of adulterated starch by particle size distribution method

[0037] After the Mastersizer2000 laser particle size analyzer was preheated for half an hour, about 0.5g of potato starch, corn starch, sweet potato starch, wheat starch and tapioca starch samples were placed on the sample tank, and the Mastersizer2000 software was started to set the parameters for automatic sampling, and the potato starch, Particle size distribution of corn starch, sweet potato starch, wheat starch, tapioca starch granules.

[0038] Table 1 The particle size distribution of different varieties of starch

[0039]

[0040] As shown in the table above, the particle size range of potato starch particles is: 5-61 μm, with an average particle size of about 15 μm; the particle size range of corn starch particles is: 5-35 μm, with an average diameter of about 14 μm, and the volume percentage of large potato starch particles is 3.5% to 4.5%, while the volume percentage ...

Embodiment 3

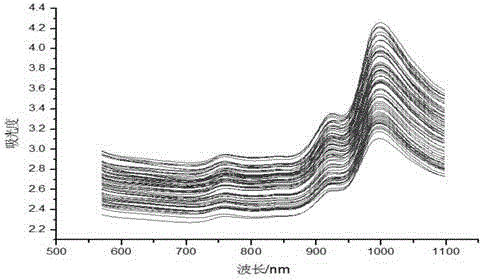

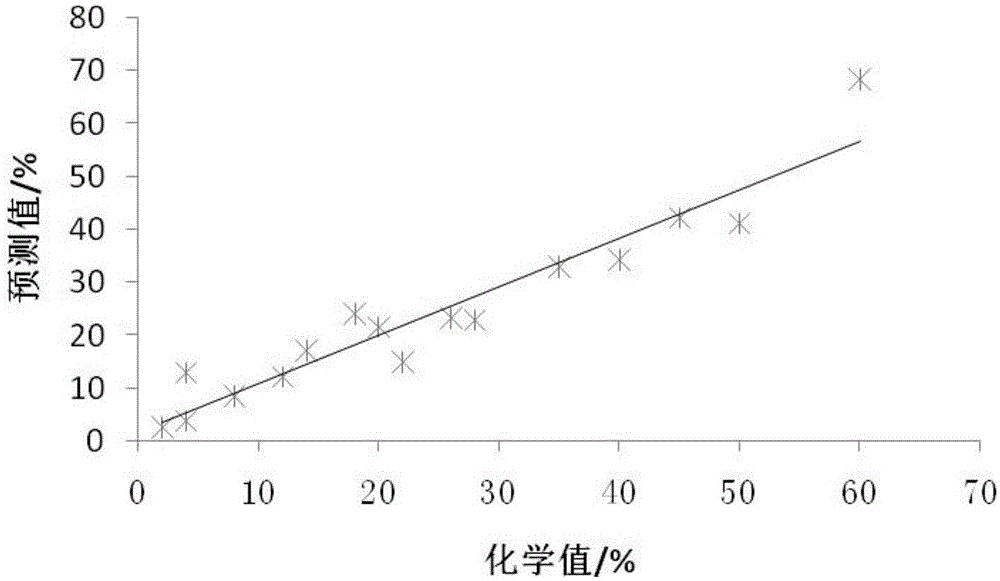

[0041] Example 3: Taking corn as an example, the near-infrared spectroscopy is used to illustrate the detection of potato starch adulterated corn starch

[0042] (1) Materials and handling:

[0043] Add different qualities of corn starch to the potato starch and mix well with a mixer. The obtained adulteration amounts were 0, 2, 4, 6, 8, 10, 12, 14, 16, 18, 20, 22, 24, 26, 28, 30, 35, 40, 45, 50, 55, 60 , 70, 80, 90% of the 100 samples, select 84 samples as the calibration set, and the remaining 16 samples as the validation set.

[0044] (2) Data processing and modeling analysis:

[0045] In this experiment, the InfratecTM1241 near-infrared grain analyzer from FOSS Company was used. The scanning range was short-wave scanning from 570 to 1098nm.

[0046] The near-infrared analysis spectrum was obtained by measurement, and the original spectrum data was converted from CSD format to NIR format by IFT3.20 software, and then analyzed by WinISIⅢ software, the abnormal samples in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com