Fermented crop straw composition and application thereof

A technology of crop straw and composition, which is applied in application, animal feed, animal feed, etc., can solve the problems of waste, low utilization rate and feeding effect, and achieve the effects of increased nutritional value, reduced crude fiber content, and good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

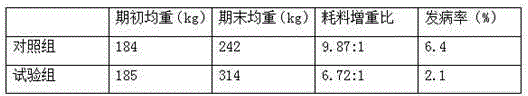

Image

Examples

Embodiment 1

[0038] A composition for fermenting crop stalks, characterized in that it comprises the following components in parts by weight:

[0039] 5 parts of molasses; 8 parts of compound bacteria; 2.5 parts of compound enzyme; 4 parts of compound trace elements; 0.5 part of urea phosphate; 0.5 part of table salt.

[0040] The above-mentioned composite bacteria are compounded after cultured by 12% of Candida utilis, 10% of Bacillus subtilis and 8% of Trichoderma viride;

[0041] The above compound enzyme is composed of 1.5 parts of cellulase and 1 part of papain;

[0042] The above-mentioned composite trace elements include 1 part of ferrous sulfate, 0.8 part of zinc sulfate, 1 part of calcium oxalate, and 1.2 parts of manganese sulfate.

[0043] The specific processing steps of the above-mentioned composition for fermenting crop stalks are as follows:

[0044] (1) collecting corn stalks, removing the soil, crushing the corn stalks, and then taking 75 parts by weight of the crushed c...

Embodiment 2

[0049] A composition for fermenting crop stalks, characterized in that it comprises the following components in parts by weight:

[0050] 8 parts of molasses; 9 parts of compound bacteria; 3.5 parts of compound enzyme; 5.5 parts of compound trace elements; 1 part of urea; 0.7 parts of table salt.

[0051] The above-mentioned composite bacteria are compounded after cultured by 14% of Candida utilis, 12% of Bacillus subtilis and 10% of Trichoderma viride;

[0052] The above compound enzyme is composed of 2 parts of cellulase and 1.5 parts of papain;

[0053] The above-mentioned composite trace elements include 1.5 parts of ferrous sulfate, 1 part of zinc sulfate, 1.6 parts of calcium oxalate, and 1.4 parts of manganese sulfate.

[0054] The specific processing steps of the above-mentioned composition for fermenting crop stalks are as follows:

[0055] (1) Collecting crop straw, straw and peanut vines, removing soil, crushing the crop straw, and then taking 80 parts by weight o...

Embodiment 3

[0060] A composition for fermenting crop stalks, characterized in that it comprises the following components in parts by weight:

[0061] 10 parts of molasses; 10 parts of compound bacteria; 4.5 parts of compound enzyme; 6.5 parts of compound trace elements; 2 parts of biuret; 1 part of table salt.

[0062] The above-mentioned composite bacteria are compounded by culturing 17% of Candida utilis, 7% of Bacillus subtilis and 12% of Trichoderma viride.

[0063] The above compound enzyme is composed of 2.5 parts of cellulase and 2 parts of papain;

[0064] The above-mentioned composite trace elements include 1.5 parts of ferrous sulfate, 1.2 parts of zinc sulfate, 2.2 parts of calcium oxalate, and 1.6 parts of manganese sulfate.

[0065] The specific processing steps of the above-mentioned composition for fermenting crop stalks are as follows:

[0066] (1) Collect crop straws, sweet potato vines, vegetable leaves and sorghum stalks, remove the soil, crush the crop straws, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com