Method for tenderizing salamander meat

A giant salamander tenderization technology, applied in the functions of food ingredients, ultra-high pressure food processing, food preparation, etc., can solve the problems of inconvenient processing and eating, complicated operability, and fragile giant salamander meat, so as to extend the shelf life and simplify protein Structure, easy to digest and absorb effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

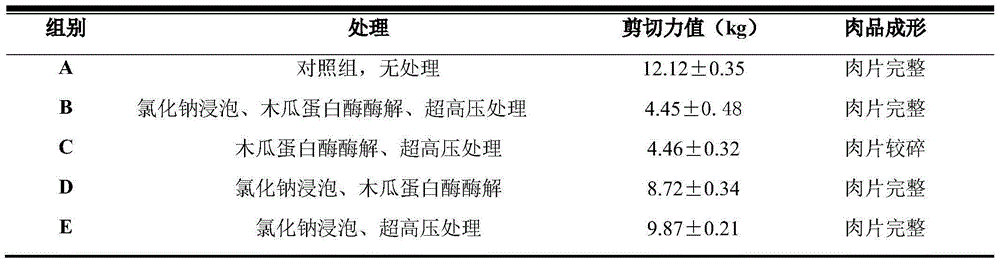

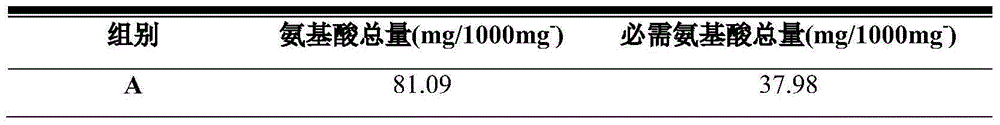

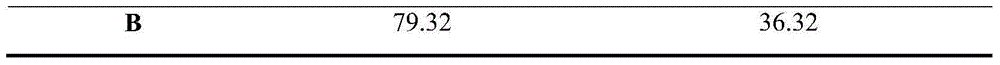

Embodiment 1

[0018] 1) A 3.5-year-old giant salamander with a weight of about 5 kg was stunned by electric shock, slaughtered, stabbed and bled, and the back meat was taken;

[0019] 2) Put the giant salamander meat into the sodium chloride solution and soak for 15 minutes, take out the soaked giant salamander meat and drain it under the ambient conditions of ozone, the mass concentration of the sodium chloride solution is 1.5%;

[0020] 3) Prepare a tenderizing solution of 0.01% meat weight for the processed giant salamander meat in step 2), and prepare under the condition of 6° C. for 12 hours. The tenderizing solution is a papain solution with a mass fraction of 1.0%. In the solution, Also contain 3wt% ginger onion water;

[0021] 4) Take out the giant salamander meat after the enzymatic hydrolysis treatment in step 3) and dry it in the air, then carry out two consecutive ultra-high pressure treatments after it is vacuum-packed. Obtain tenderized giant salamander meat.

Embodiment 2

[0023] 1) A 4-year-old giant salamander with a weight of about 6 kg was stunned by electric shock, slaughtered, stabbed and bled, and the back meat was taken;

[0024] 2) Put the giant salamander meat into the sodium chloride solution and soak for 10 minutes, take out the soaked giant salamander meat and drain it under the ambient conditions of ozone, the mass concentration of the sodium chloride solution is 1.5%;

[0025] 3) For the processed giant salamander meat in step 2), prepare a tenderizing solution with a meat weight of 0.01%, and prepare it at 6° C. for 12 hours. The tenderizing solution is a papain solution with a mass fraction of 0.50%. In the solution, Also contain 5wt% ginger onion water;

[0026] 4) Take out the giant salamander meat after the enzymatic hydrolysis treatment in step 3) and dry it in the air, then carry out two consecutive ultra-high pressure treatments after it is vacuum-packed. Obtain tenderized giant salamander meat.

Embodiment 3

[0028] 1) A 4-year-old giant salamander with a weight of about 6 kg was stunned by electric shock, slaughtered, stabbed and bled, and the back meat was taken;

[0029] 2) Prepare a tenderizing solution of 0.01% meat weight for the giant salamander meat that has been processed in step 1), and prepare under the condition of 6° C. for 12 hours. The tenderizing solution is a papain solution with a mass fraction of 0.50%. In the solution, Also contain 5wt% ginger onion water;

[0030] 3) Take out the giant salamander meat after the enzymatic hydrolysis treatment in step 2) and dry it in the air, then carry out two consecutive ultra-high pressure treatments after vacuum packaging, the first time at 250MPa, hold the pressure for 10 minutes, and the second time at 400MPa for 7 minutes Obtain tenderized giant salamander meat, although the tenderized giant salamander meat is obtained, but the meat is fragile and shapeless.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com