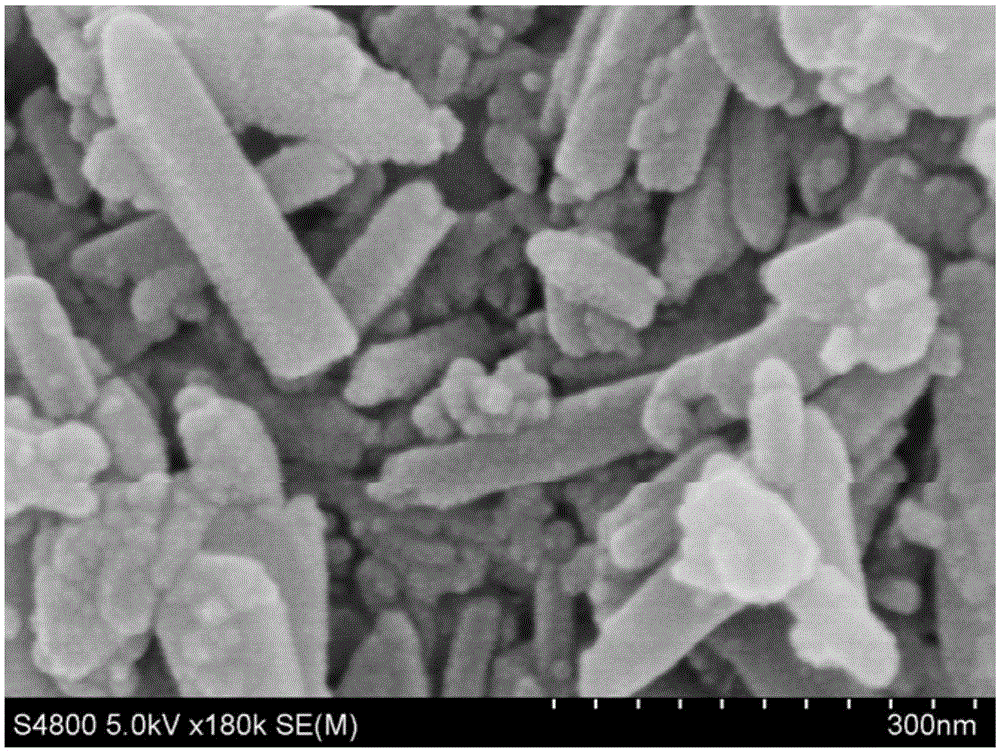

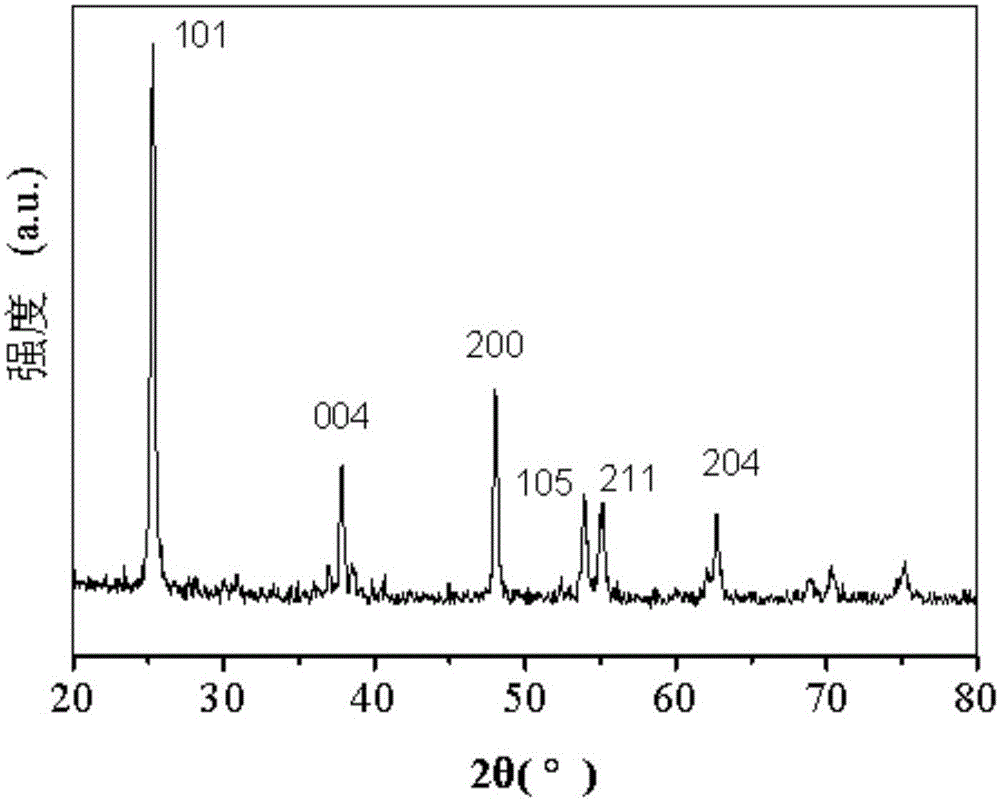

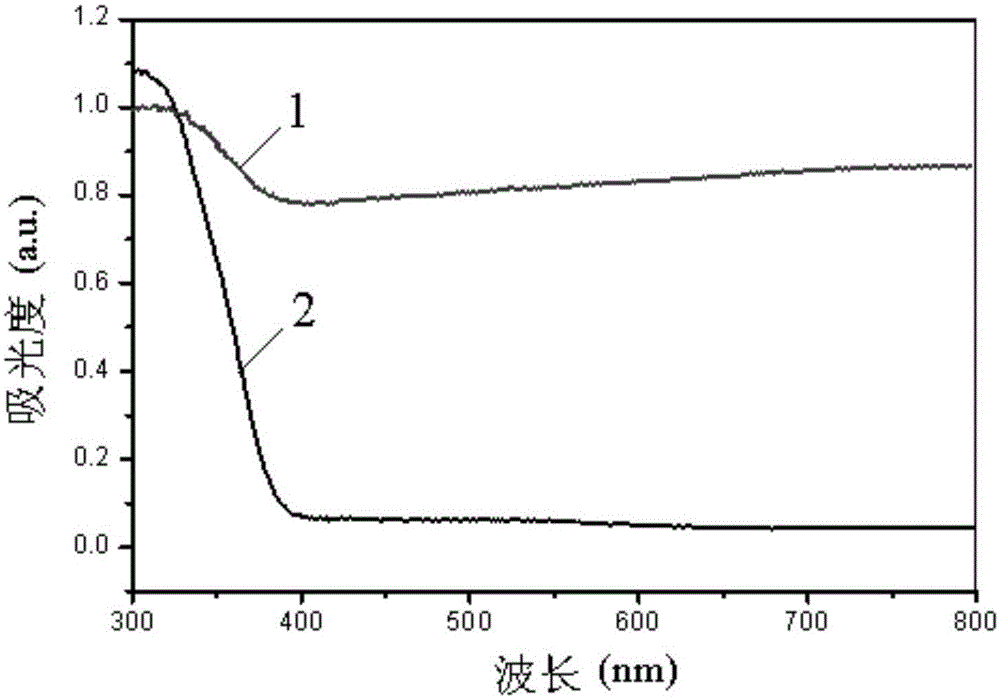

Preparation method of black titanium dioxide nano rod visible light catalyst

A technology of titanium dioxide and photocatalyst, which is applied in the field of preparation of visible light photocatalyst, can solve the problems of low charge transfer efficiency and low utilization rate of the catalyst, and achieve the effects of relatively low price, simple operation and simple experimental equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Specific embodiment one: this embodiment is a kind of preparation method of black titanium dioxide nanorod visible light photocatalyst is prepared according to the following method:

[0031] 1. Preparation of mixed solution: Dissolve ammonium chloride in isopropanol, then stir for 1min to 10min at a stirring speed of 15r / min to 30r / min, then add titanium source, and then stir at a stirring speed of 15r / min to 30r / min Stir for 10min to 50min at a stirring speed of 10min to 50min, then add ammonia water with a mass fraction of 25% to 28%, and then stir for 1min to 10min at a stirring speed of 15r / min to 30r / min to obtain a mixed solution;

[0032] The mass of ammonium chloride described in step 1 and the volume ratio of isopropanol are 1g:(0.5mL~100mL);

[0033] The mass of ammonium chloride described in step 1 and the volume ratio of titanium source are 1g:(0.005mL~5mL);

[0034] The volume ratio of the mass of ammonium chloride described in step 1 to the ammoniacal liq...

specific Embodiment approach 2

[0051] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the titanium source described in step 1 is titanium tetraisopropoxide. Others are the same as the first embodiment.

specific Embodiment approach 3

[0052] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step two, the mixed solution obtained in step one is added to the reactor, and then the reactor is reacted at a temperature of 150° C. for 60 h, Obtain the reaction solution. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com