Environment-friendly silver-free welding rod

A welding rod and environmental protection technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of increased cost pressure, small advantages, toxic vapor, etc., and achieve good air tightness and low preparation cost. , the effect of simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

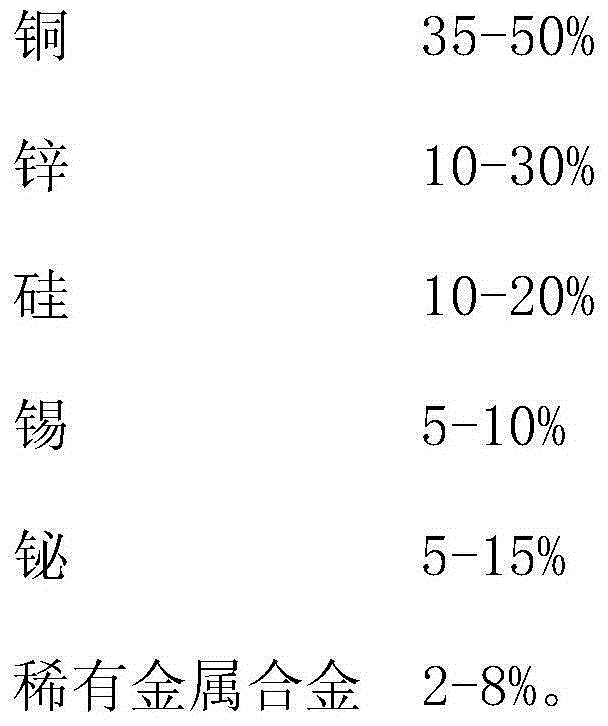

[0014] Environmentally friendly silver-free welding rods are composed of the following components by mass percentage:

[0015]

Embodiment 2

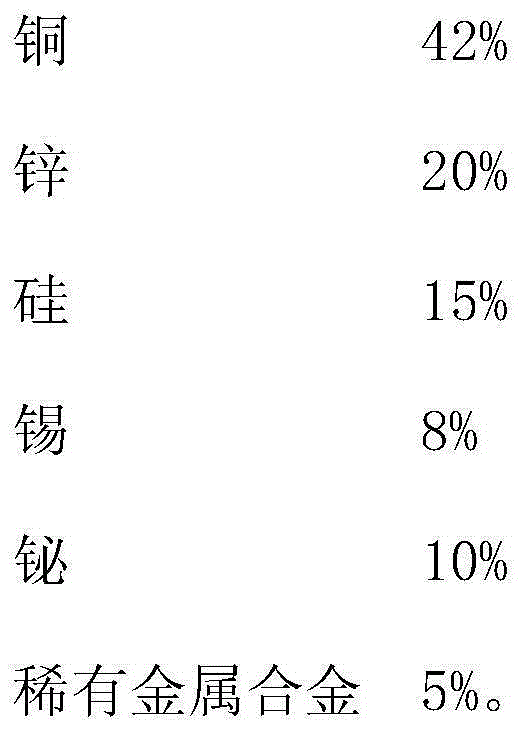

[0017] Environmentally friendly silver-free welding rods are composed of the following components by mass percentage:

[0018]

[0019] Rare metal alloys include rare earths, vanadium, lithium.

[0020] The relevant technical parameters of the welding rod of the present invention are as follows:

[0021] Solidus: 837 degrees Celsius.

[0022] Liquidus: 887 degrees Celsius

[0023] Permeability: 4.00mm-5.13mm

[0024] Welding strength: 290MPa.

[0025] The invention has the advantages of good welding effect, good braze penetration rate, large infiltration amount, good strength, good air tightness, low cost, no pollution, and can better replace silver-containing solder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com