Method for quickly starting denitrifying desulfurization process

A denitrification and desulfurization, fast-start technology, applied in chemical instruments and methods, anaerobic digestion treatment, biological water/sewage treatment, etc. problem, to achieve the effect of easy control, stable and efficient processing performance, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

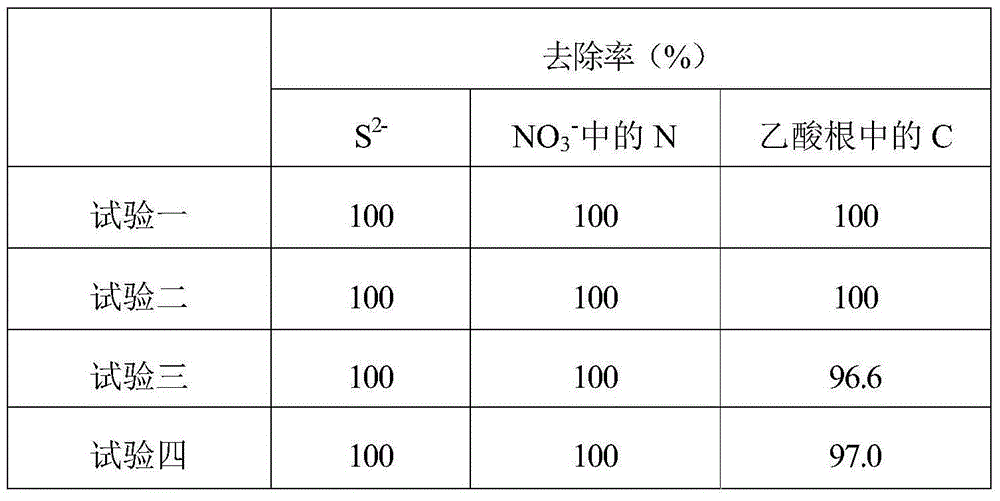

[0018] Specific implementation mode 1: This implementation mode is a method for quickly starting the denitrification desulfurization process, which is specifically carried out according to the following steps:

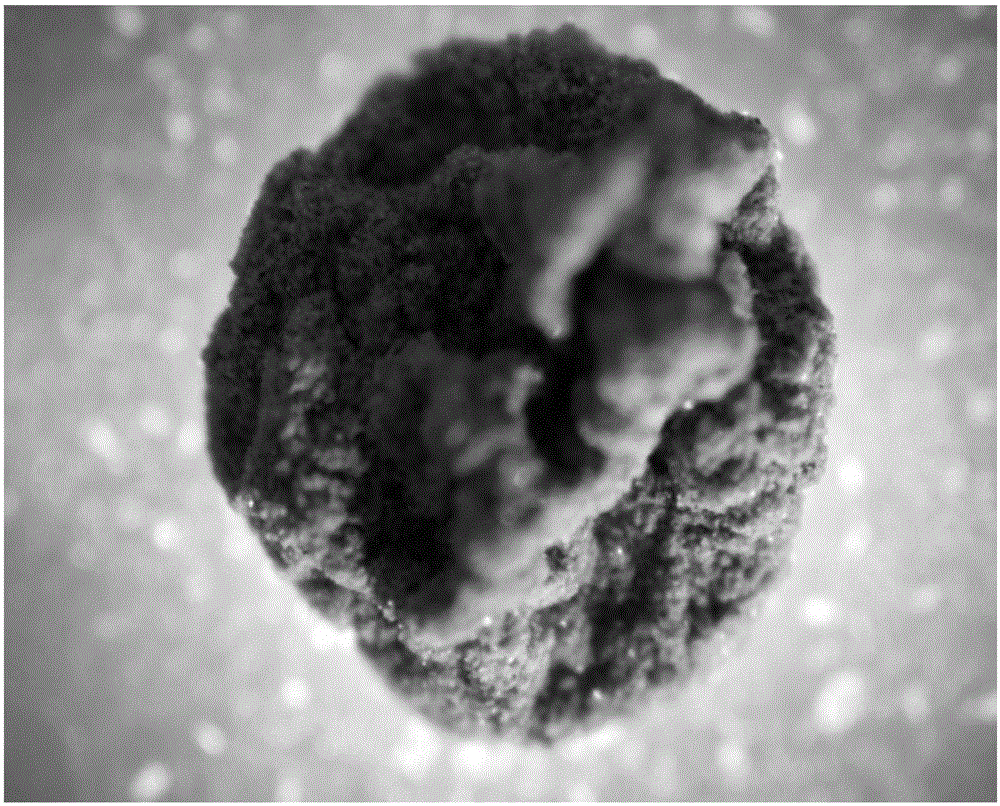

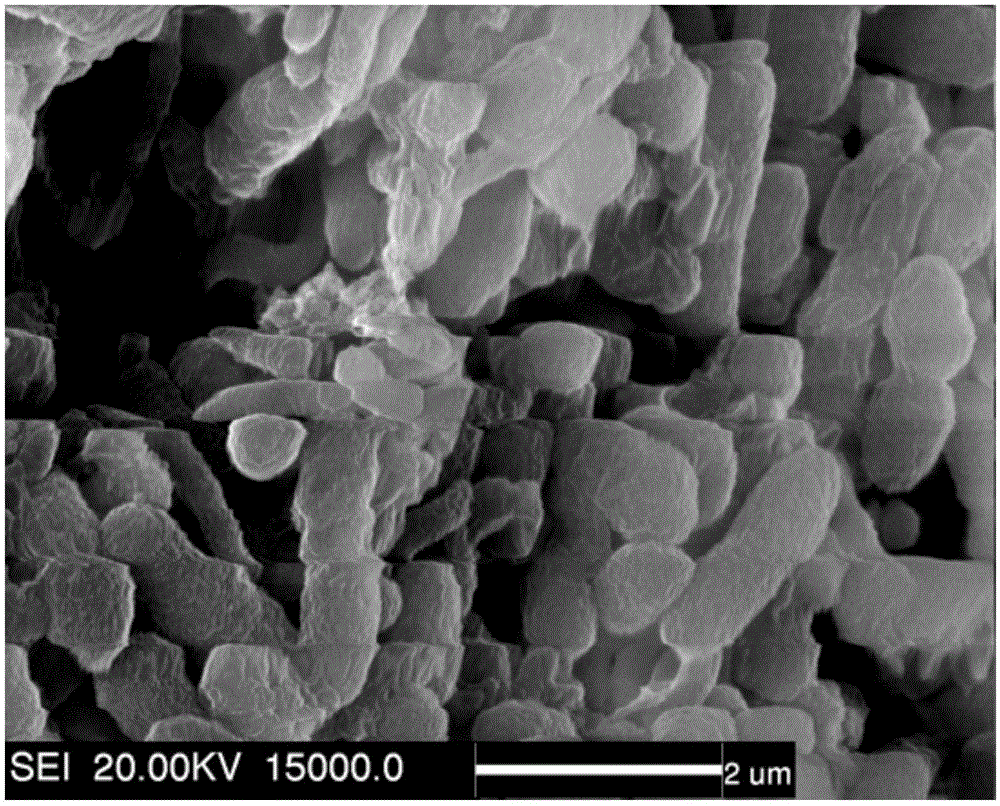

[0019] 1. Form stable and mature granular sludge: Add the activated sludge in the secondary sedimentation tank of the sewage treatment plant into the expanded granular sludge bed reactor, and then pass it into wastewater I, and adjust the temperature of the expanded granular sludge bed reactor to 27 ℃ ~ 29 ℃, use sodium bicarbonate to adjust the pH of the expanded granular sludge bed reactor to 7.7 ~ 8.3, the hydraulic retention time is 24h, run continuously for 25 days, and form stable and mature particles in the expanded granular sludge bed reactor sludge;

[0020] The concentration of all components in the waste water I described in step one is: SO 4 2- 1000mg / L, NO 3 - 500mg / L, K 2 HPO 4 ·3H 2 O is 220.6mg / L, NH 4 Cl is 573.2mg / L, Ca 2+ 25mg / L, Mg 2+ The ...

specific Embodiment approach 2

[0023] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 1, sodium bicarbonate is used to adjust the pH of the expanded granular sludge bed reactor to 8.0. Others are the same as the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the concentration of all components in the waste water I described in step one is: SO 4 2- 1000mg / L, NO 3 - 500mg / L, K 2 HPO 4 ·3H 2 O is 220.6mg / L, NH 4 Cl is 573.2mg / L, Ca 2+ 25mg / L, Mg 2+ 10mg / L, COD 2000mg / L, trace element solution 1mL / L. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com