Organic phosphonium molybdenum complex, preparation method and application

A technology of organic phosphine and complexes, applied in the field of preparation of organic phosphine-molybdenum complexes, can solve the problems of not being able to meet high-efficiency production, insolubility, and low catalytic efficiency, and achieve suitable for large-scale industrial production, low cost, and high catalytic efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

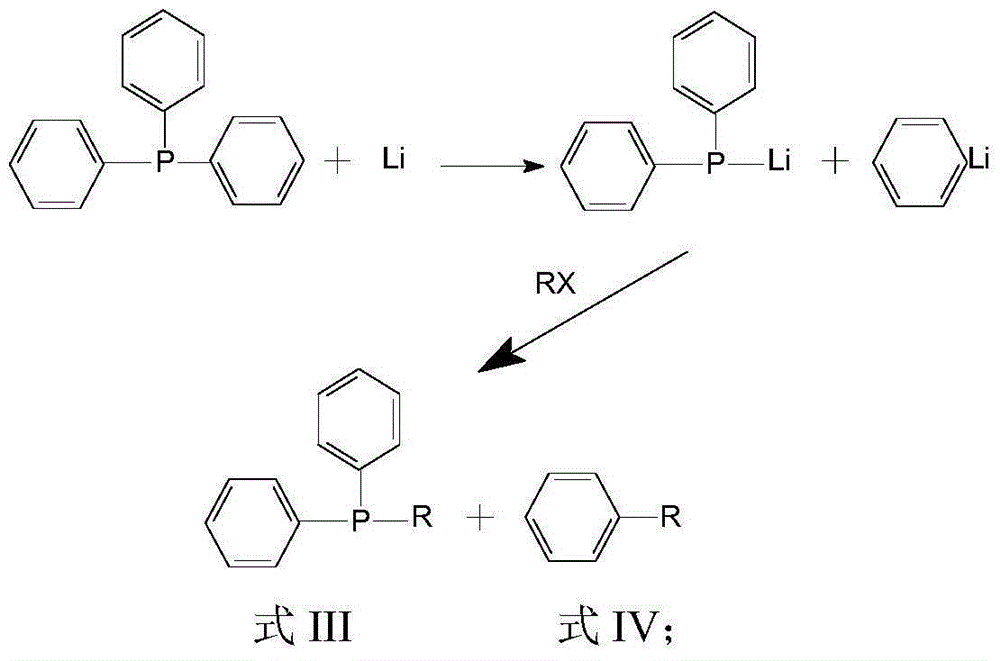

Method used

Image

Examples

Embodiment 1

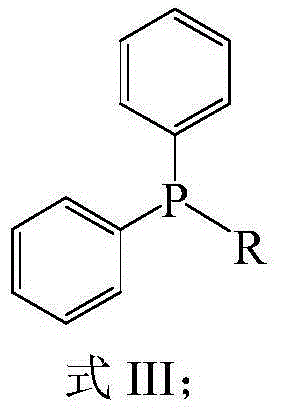

[0042] The organophosphine molybdenum complex of this embodiment is a propyl diphenylphosphine molybdenum complex, which has the following molecular formula:

[0043] Mo[P(Ph) 2 CH 2 CH 2 CH 3 ] 2 Cl 5 Formula I-1;

[0044] In Formula I-1, P(Ph) 2 CH 2 CH 2 CH 3 For propyl diphenyl phosphine.

[0045]The preparation method of the organophosphine-molybdenum complex of this embodiment is to add 273.2g (1mol) of molybdenum pentachloride into 500ml of dry chloroform under nitrogen protection, stirring and 30°C, and wait until the molybdenum pentachloride is completely dissolved. Finally, the chloroform solution of molybdenum pentachloride is obtained; the chloroform solution of the propyl diphenylphosphine that is dissolved in 456.38g (2mol) is added dropwise in the chloroform solution of molybdenum pentachloride, 30 ℃ of insulation reaction 5h, obtain the concentration of 1mol / L chloroform solution of propyl diphenylphosphine molybdenum complex.

[0046] The chlorofor...

Embodiment 2

[0052] The organophosphine-molybdenum complex of this embodiment is a hexyldiphenylphosphine-molybdenum complex, which has the following molecular formula:

[0053] Mo[P(Ph) 2 CH 2 CH 2 CH 2 CH 2 CH 2 CH 3 ] 2 Cl 5 Formula I-2;

[0054] In formula I-2, P(Ph) 2 CH 2 CH 2 CH 2 CH 2 CH 2 CH 3 For hexyl diphenyl phosphine.

[0055] The preparation method of the organophosphine-molybdenum complex of the present embodiment is to add 218.56 g (0.8 mol) of molybdenum pentachloride into 500 ml of dry toluene under nitrogen protection, stirring and 50° C., and wait until the molybdenum pentachloride is completely After dissolving, the toluene solution of molybdenum pentachloride was obtained; the toluene solution dissolved with 432.3g (1.6mol) of hexyldiphenylphosphine was added dropwise to the toluene solution of molybdenum pentachloride, and the temperature was kept at 50°C for 4h to obtain the concentration It is a toluene solution of 0.8mol / L hexyl diphenylphosphine...

Embodiment 3

[0062] The organophosphine-molybdenum complex of this embodiment is an octyldiphenylphosphine-molybdenum complex, which has the following molecular formula:

[0063] Mo[P(Ph) 2 CH 2 CH 2 CH 2 CH 2 CH 2 CH 2 CH 2 CH 3 ] 2 Cl 5 Formula I-3;

[0064] In formula I-3, P(Ph) 2 CH 2 CH 2 CH 2 CH 2 CH 2 CH 2 CH 2 CH 3 For octyl diphenyl phosphine.

[0065] The preparation method of the organophosphine-molybdenum complex of the present embodiment is to add 136.6 g (0.5 mol) of molybdenum pentachloride into 500 ml of dry ethylbenzene under nitrogen protection, stirring and 60° C. After molybdenum was completely dissolved, the ethylbenzene solution of molybdenum pentachloride was obtained; the ethylbenzene solution of octyldiphenylphosphine that was dissolved in 298.19g (1mol) was added dropwise in the ethylbenzene solution of molybdenum pentachloride, The reaction was carried out at 60°C for 3 hours to obtain an ethylbenzene solution of octyl diphenylphosphine molyb...

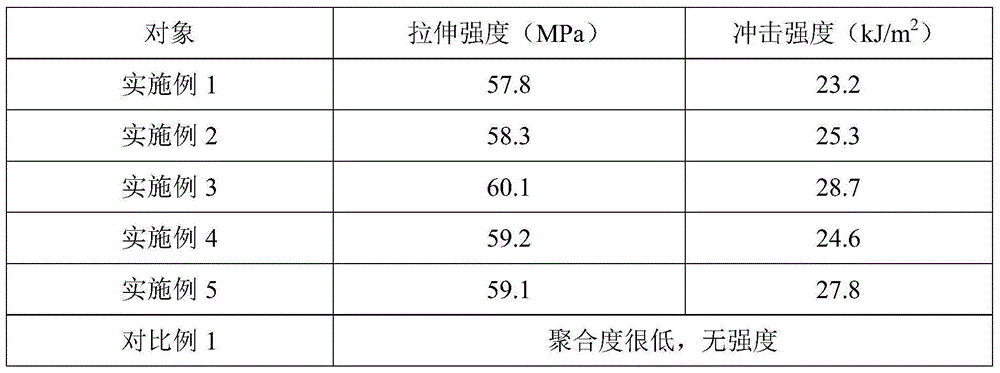

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com