DOPO type reactive flame retardant with terminal group as epoxy group, preparation method therefor and application thereof

A technology of reactive flame retardants and epoxy groups, which is applied to the DOPO type reactive flame retardants whose terminal groups are epoxy groups and its preparation and application fields. It can solve the problems of harsh and complicated synthesis conditions and avoid the production process. , simple synthesis process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

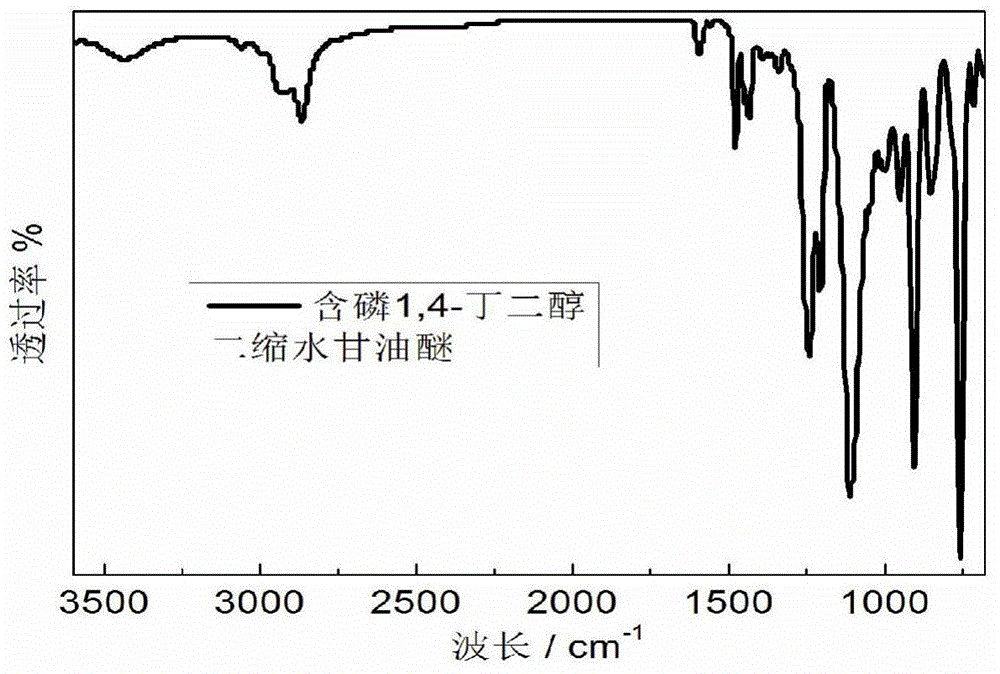

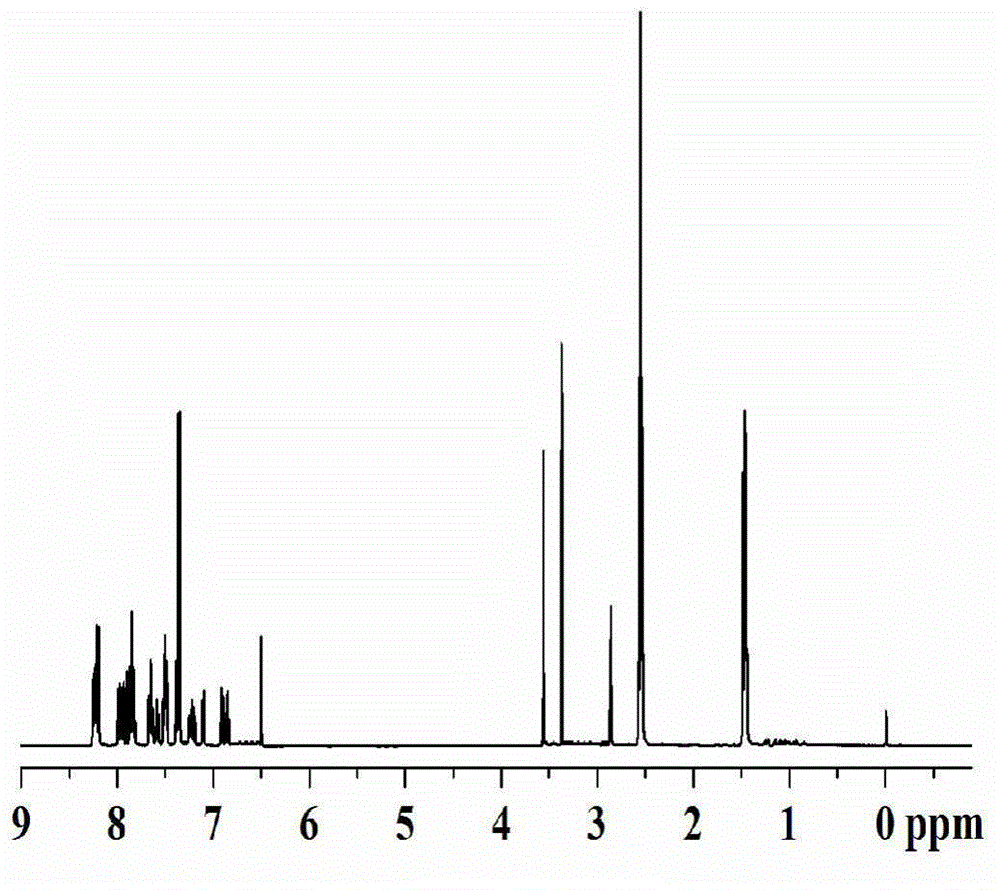

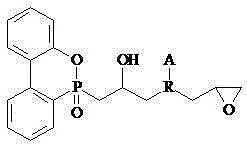

[0047] Add 110g (0.5mol) of 1,4-butanediol diglycidyl ether and 200mL of absolute ethanol into a dry three-necked flask, raise the temperature to 120°C, and stir well. Add 108g (0.5mol) of DOPO into the reaction flask in 5 batches, stir until the solid is completely dissolved and the solution is transparent. After heat preservation at 120°C for 10 hours, cool to room temperature, remove the solvent under reduced pressure to obtain a colorless transparent viscous liquid, dry at 80°C to obtain a phosphorus-containing glycidyl flame retardant with a phosphorus content of 7.41%. Infrared and NMR characterization of samples, such as figure 1 , figure 2 As shown, it can be seen from the graph that the prepared phosphorus-containing glycidyl flame retardant is phosphorus-containing 1,4-butanediol diglycidyl ether.

[0048] 112g (0.056mol) polyester ethylene adipate diol, 6g (0.097mol) ethylene glycol, 5g (0.055mol) 1,4-butanediol, 120mL N,N-dimethylformamide, 0.02 g dibutyltin di...

Embodiment 2

[0050] Add 120g (0.5mol) of resorcinol diglycidyl ether and 200mL of absolute ethanol into a dry three-necked flask, raise the temperature to 120°C, and stir evenly. Add 108g (0.5mol) of DOPO into the reaction flask in 5 batches, stir until the solid is completely dissolved and the solution is transparent. After heat preservation at 120°C for 10 hours, cool to room temperature, remove the solvent under reduced pressure to obtain a colorless transparent viscous liquid, and dry at 80°C to obtain a phosphorus-containing glycidyl flame retardant with a phosphorus content of 6.80%.

[0051] 112g (0.056mol) polyester ethylene adipate diol, 6g (0.097mol) ethylene glycol, 5g (0.055mol) 1,4-butanediol, 120mL N,N-dimethylformamide, 0.02 g dibutyltin dilaurate, mix well under stirring at 85°C, first add 37.5g (0.15mol) and 12.5g (0.05mol) of MDI in batches, toluene to adjust the viscosity, then add 10.42g (0.041mol) in batches MDI, the viscosity of the polyurethane is 40000-80000pps, ad...

Embodiment 3

[0053] Add 154.5g (0.5mol) of triglycidyl p-aminophenol and 200mL of absolute ethanol into a dry three-necked flask, heat up to 120°C, and stir evenly. Add 108g (0.5mol) of DOPO into the reaction flask in 5 batches, stir until the solid is completely dissolved and the solution is transparent. After heat preservation at 120°C for 10 hours, cool to room temperature, remove the solvent under reduced pressure to obtain a colorless transparent viscous liquid, and dry at 80°C to obtain a phosphorus-containing glycidyl flame retardant with a phosphorus content of 8.37%.

[0054] 112g (0.056mol) polyester ethylene adipate diol, 6g (0.097mol) ethylene glycol, 5g (0.055mol) 1,4-butanediol, 120mL N,N-dimethylformamide, 0.02 g dibutyltin dilaurate, mix well under stirring at 83°C, first add 37.5g (0.15mol) and 12.5g (0.05mol) of MDI in batches, toluene to adjust the viscosity, then add 10.07g (0.041mol) in batches MDI, the viscosity of the polyurethane is 40000-80000pps, add 23.65g (0.03...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com