Method for improving yield of biodiesel prepared through kitchen grease enzymic method through pretreatment

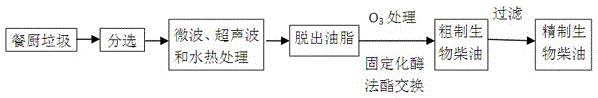

A biodiesel and enzymatic preparation technology, which is applied in the direction of biofuel, fatty substance recovery, recycling technology, etc., can solve the problems of low oil and fat precipitation from kitchen waste and low biodiesel production, and increase the precipitation of slick oil , promote transesterification reaction, increase the effect of diffusion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for utilizing pretreatment to improve the production of biodiesel produced by enzymatic method of kitchen grease, comprising the steps of:

[0055] S1. Remove chopsticks, plastic bags and other sundries in the kitchen waste, and carry out microwave, ultrasonic and hydrothermal treatment on the kitchen waste in sequence; the power of the microwave is 1000kw, so that the temperature of the kitchen grease is maintained at 110°C, and the treatment time is 20min; the power of the ultrasonic wave is 800w / L, and the treatment time is 15min; the hydrothermal treatment temperature is 180°C, and the treatment time is 90min; the above-mentioned treatment is carried out in an integrated equipment equipped with microwave generator, ultrasonic generator and hydrothermal device conduct.

[0056] S2. Spray the food waste treated by S1 into another container, let it stand still to separate the three phases, and collect the floating oil in the upper layer.

[0057] S3. pass int...

Embodiment 2

[0065] The steps for preparing biodiesel in this example are basically the same as in Example 1, except that the compound lipase described in S3 and the immobilized compound lipase described in S4 are Geotrichum candidum lipase, Candida lipase and Burkhall onion The mass ratio of each enzyme of German bacteria lipase is 0.2:10:1.5 in step S3 and 1:1:25 in step S4.

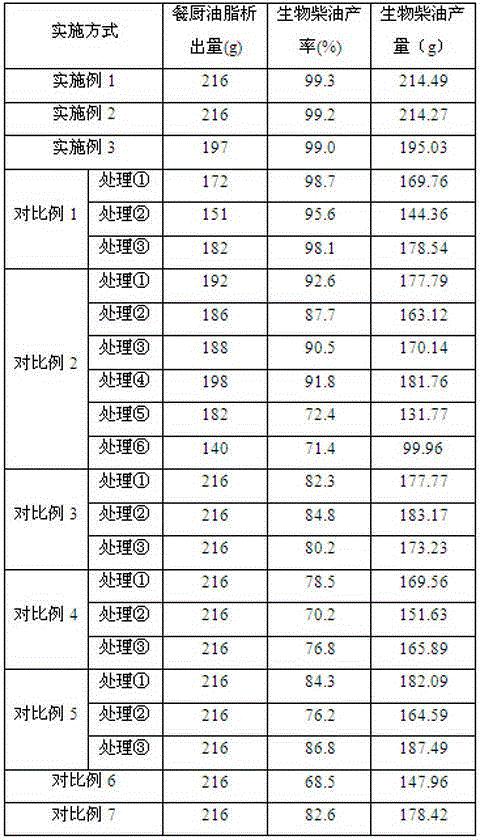

[0066] The results of biodiesel preparation according to the above steps are shown in Table 1.

Embodiment 3

[0068] The steps for preparing biodiesel in this example are basically the same as in Example 1, the difference is that: ① The three-phase separation in step S2 is to release the pressure to normal pressure, and the kitchen waste is sent to the three-phase separator, and the kitchen waste is obtained after standing still. Grease, without spraying the food waste to another container; ② Geotrichum candidum lipase, Candida lipase and Burkholm onion in the composite lipase described in S3 and the immobilized composite lipase described in S4 The mass ratio of each enzyme of Erdella lipase is 6:1:15 in step S3 and 10:10:5 in step S4.

[0069] The results of biodiesel preparation according to the above steps are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com