Cascade recovery method for arsenic-containing antimony-containing gold ore difficult to process

A technology for cascade recovery and gold mining, which is applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of inability to directly apply the separation and extraction of low-antimony-containing minerals, and achieves improved gold and silver recovery rate, low energy consumption, and high technology. short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

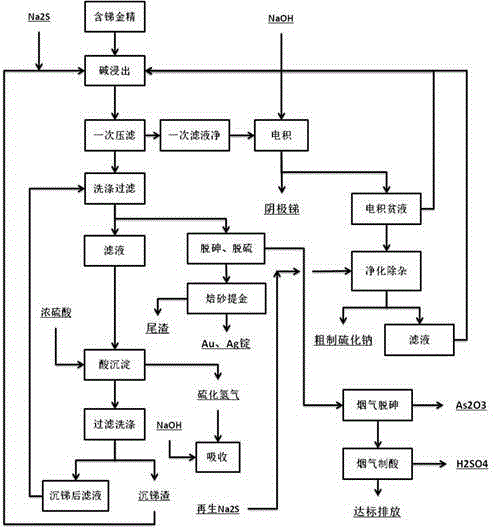

Image

Examples

Embodiment Construction

[0028] A cascade recovery method for refractory gold ores containing arsenic and antimony, (1) using refractory gold concentrates containing arsenic and antimony as raw materials, first adding sodium sulfide under alkaline conditions, and selectively leaching antimony under controlled conditions . (2) Liquid-solid separation of leached ore slurry, electrowinning of leachate to obtain cathode antimony, return of poor electrowinning solution to the leaching section for recycling, and purify and remove impurities from electrowinning poor solution. (3) The leaching slag is washed, the washing liquid is added with concentrated sulfuric acid to precipitate antimony, the liquid after antimony precipitation is returned to the washing cycle, and the antimony precipitation slag is returned to leaching. (4) Then roast the leaching residue to remove arsenic and desulfurize, so that arsenic and sulfur enter the flue gas, the flue gas is chilled and crystallized to recover arsenic trioxide,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com