A kind of environment-friendly cyanide-free alkaline galvanizing electroplating solution and galvanizing process

A cyanide-free alkaline galvanizing and electroplating solution technology, applied in electrolytic process, electrolytic components, cells, etc., can solve the problems of uneven coating thickness, imperfect coating, air flow, scars, etc., and achieve good coating adhesion and improve Surface gloss and stability, surface leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

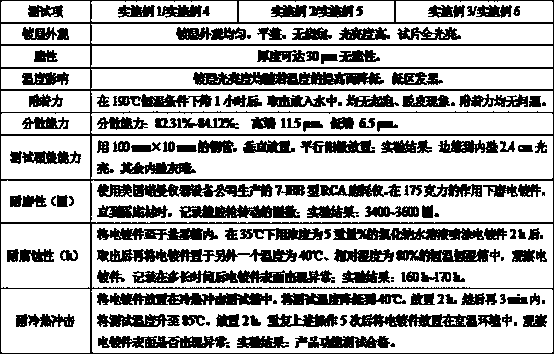

Examples

Embodiment 1

[0040] An environment-friendly cyanide-free alkaline galvanizing electroplating solution provided by the invention, said cyanide-free alkaline galvanizing electroplating solution is composed of the following components:

[0041] Zinc 10 g / L

[0042] Sodium hydroxide 130 g / L

[0043] Regulator 25 ml / L

[0044] Cylinder opener 6 ml / L

[0045] Brightener 1 ml / L

[0046] Humectant 0.1 ml / L

[0047] Wherein, the brightener is prepared by the following method: 10 parts of polyethyleneimine, 15 parts of imidazole propoxy condensate, 25 parts of nitrogen heterocyclic derivatives, 13 parts of modified aromatic aldehyde compounds and 400 parts of water Add it into the reactor and raise the temperature to 45°C; add 70 parts of epichlorohydrin into the dropping funnel, slowly drop it into the reactor and stir the reaction, the reaction temperature does not exceed 45°C, and the dropping time is 3~5 h; after Step S2 After the dropwise addition of epichlorohydrin is completed, the tempe...

Embodiment 2

[0050] An environment-friendly cyanide-free alkaline galvanizing electroplating solution provided by the invention, said cyanide-free alkaline galvanizing electroplating solution is composed of the following components:

[0051] Zinc 11 g / L

[0052] Sodium hydroxide 140 g / L

[0053] Regulator 27 ml / L

[0054] Cylinder opener 7 ml / L

[0055] Brightener 2 ml / L

[0056] Humectant 0.2 ml / L

[0057]Wherein, the brightener is prepared by the following method: 15 parts of polyethyleneimine, 20 parts of imidazole propoxy condensate, 30 parts of nitrogen heterocyclic derivatives, 18 parts of modified aromatic aldehyde compounds and 450 parts of water Add it into the reactor and raise the temperature to 45°C; add 75 parts of epichlorohydrin into the dropping funnel, slowly drop it into the reactor and stir the reaction, the reaction temperature does not exceed 45°C, and the dropping time is 3~5 h; after Step S2 After the dropwise addition of epichlorohydrin is completed, the temper...

Embodiment 3

[0060] An environment-friendly cyanide-free alkaline galvanizing electroplating solution provided by the invention, said cyanide-free alkaline galvanizing electroplating solution is composed of the following components:

[0061] Zinc 12 g / L

[0062] Sodium hydroxide 145 g / L

[0063] Regulator 30 ml / L

[0064] Cylinder opener 8 ml / L

[0065] Brightener 3 ml / L

[0066] Humectant 0.3 ml / L

[0067] Wherein, the brightener is prepared by the following method: 20 parts of polyethyleneimine, 25 parts of imidazole propoxy condensate, 35 parts of nitrogen heterocyclic derivatives, 13~23 parts of modified aromatic aldehyde compounds and 500 parts Add part of water into the reactor, raise the temperature to 45°C; add 80 parts of epichlorohydrin into the dropping funnel, slowly drop into the reactor and stir for reaction, the reaction temperature does not exceed 45°C, and the dropping time is 3~5 h ; After the epichlorohydrin is added dropwise in step S2, the temperature of the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com