High pixel image sensor packaging structure and manufacturing method thereof

A technology of image sensor and packaging structure, which is applied in the direction of electric solid-state devices, semiconductor devices, radiation control devices, etc. It can solve the problems of product failure, large difference in thermal expansion coefficient, small strength and rigidity of supporting walls, etc., and achieve the reduction of impurities and particles , meet the distance requirements, and improve the effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Specific embodiments of the present invention will be described below with reference to the accompanying drawings, wherein the corresponding structures in different embodiments use the same reference numerals, but it does not mean that there is necessarily a correlation between different embodiments and / or structures. For the convenience of illustration, some existing conventional structures are shown in simplified structures in the drawings, and the structures in the drawings are not scaled to the same scale, so they do not represent the actual relative sizes of the structures in the embodiments.

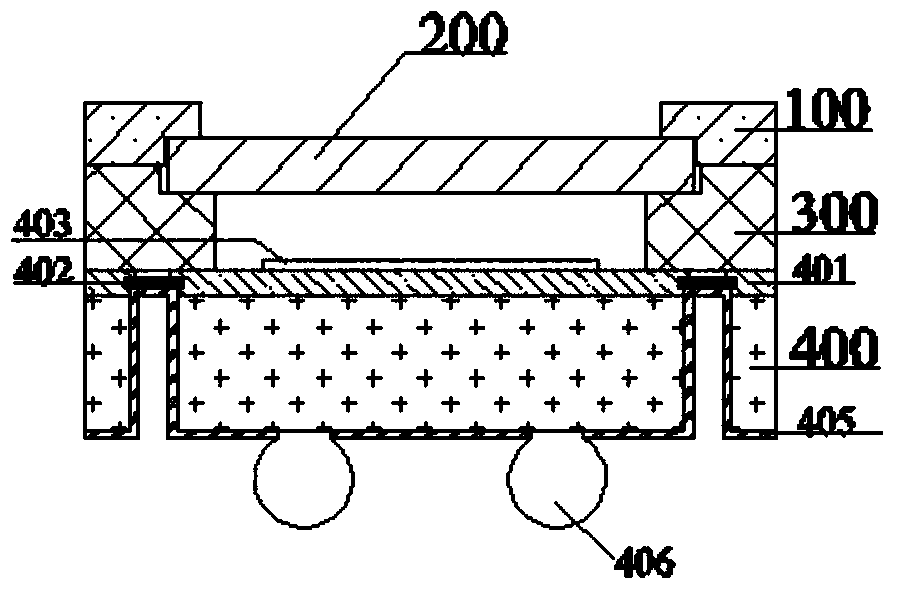

[0065] refer to figure 1 , which is a schematic diagram of a high pixel image sensor package according to an embodiment of the present invention. The structure includes:

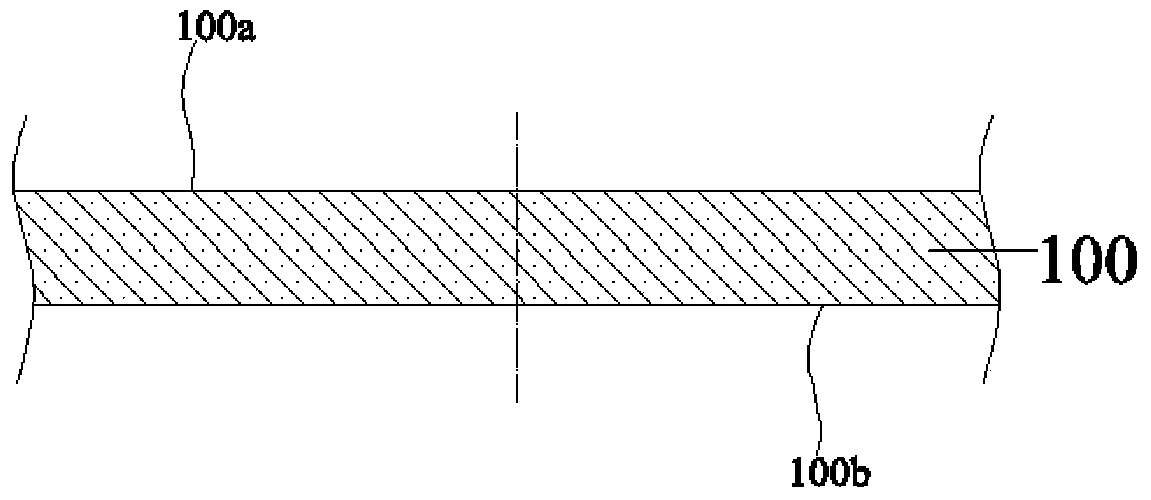

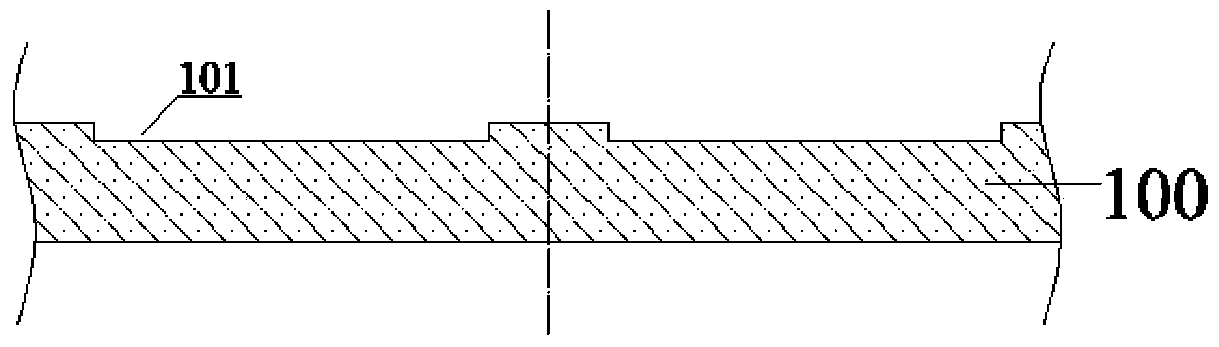

[0066] The cover plate (100) comprises a cover plate first surface (100a) and a cover plate second surface (100b), (100a), (100b) are the upper and lower surfaces of the cover plate (100); the cover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com