Microcapsule suspension containing fosthiazate and beta-cyfluthrin

A high-efficiency cyfluthrin and microcapsule suspension technology, which is applied in the direction of insecticides, biocides, biocides, etc., can solve the problems of the environment and workers, and achieve low environmental pollution, long-lasting effect, and easy degradation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

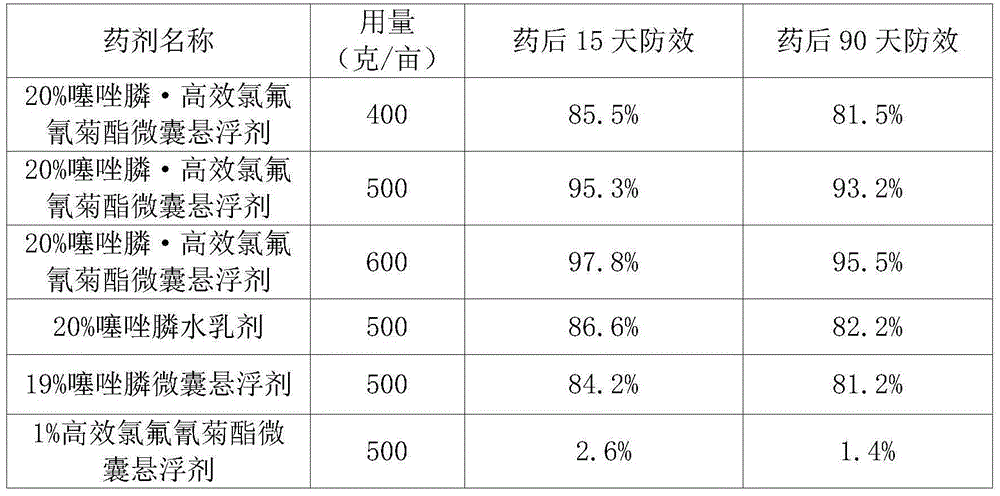

Examples

Embodiment 1

[0027] Embodiment 1: 20% thiazophosphine·beta-cyfluthrin microcapsule suspension.

[0028] 1. Preparation method:

[0029] (1) Accurately weigh 8 grams of capsule wall gelatin / gum arabic / sodium alginate, in which gelatin: gum arabic: sodium alginate is 1:1:1, add the remaining amount of deionized water, mix well, heat and stir, and control the temperature At 60-70°C, make it completely melted and ready for use.

[0030] (2) Accurately weigh 19 grams of thiazophosphine and 1 gram of beta-cyfluthrin, fully and evenly dissolve them with 3 grams of xylene, add 3 grams of emulsifier alkylarylphenol polyoxyethylene ether phosphate, castor oil 1.5 grams of polyoxyethylene ether, set aside.

[0031] (3) In the case of step (1) stirring, the temperature is controlled at 60-70 ° C, add 2 grams of dispersant alkylaryl polyoxypropylene polyoxyethylene ether, and then slowly add step (2) to make it mixed and emulsified uniform.

[0032] (4) Carry out granulation with the sharp hole met...

Embodiment 2

[0036] Example 2: 30% thiazophosphine·beta-cyfluthrin microcapsule suspension.

[0037] 1. Preparation method:

[0038] (1) Accurately weigh 10 grams of capsule wall gelatin / gum arabic / sodium alginate, in which gelatin: gum arabic: sodium alginate is 1:1:1, add the rest of deionized water, mix well, heat and stir, and control the temperature At 60-70°C, make it completely melted and ready for use.

[0039] (2) Accurately weigh 25 grams of thiazophosphine and 5 grams of beta-cyfluthrin, fully and evenly dissolve them with 8 grams of xylene, add 4.5 grams of emulsifier alkylarylphenol polyoxyethylene ether phosphate, castor oil 2 grams of polyoxyethylene ether, set aside.

[0040] (3) In the case of step (1) stirring, the temperature is controlled at 60-70 ° C, add 3.5 grams of dispersant alkylaryl polyoxypropylene polyoxyethylene ether, and then slowly add step (2) to make it mixed and emulsified uniform.

[0041] (4) Carry out granulation with the sharp hole method, and th...

Embodiment 3

[0045] Embodiment 3: 20% thiazophosphine·beta-cyfluthrin microcapsule suspension.

[0046] 1. Preparation method:

[0047] (1) Accurately weigh 8 grams of capsule wall gelatin / gum arabic / sodium alginate, in which gelatin: gum arabic: sodium alginate is 1:1:1, add the remaining amount of deionized water, mix well, heat and stir, and control the temperature At 60-70°C, make it completely melted and ready for use.

[0048] (2) Accurately weigh 19 grams of thiazophosphine technical substance and 1 gram of beta-cyfluthrin technical substance, fully dissolve it completely and evenly with 3 grams of xylene, add 3 grams of emulsifier alkylbenzene sulfonate, alkylphenol polyoxyethylene Phosphate 1.5 grams, set aside.

[0049] (3) In the case of step (1) stirring, the temperature is controlled at 60-70 ° C, add 2 grams of dispersant alkylphenol polyoxyethylene ether formaldehyde condensate sulfate, and then slowly add step (2) to make it mix Emulsifies evenly.

[0050] (4) Carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com