Coating preservation method for meat

A technology for coating fresh-keeping and meat, which is applied in the direction of preserving meat/fish with a protective coating, which can solve problems such as incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

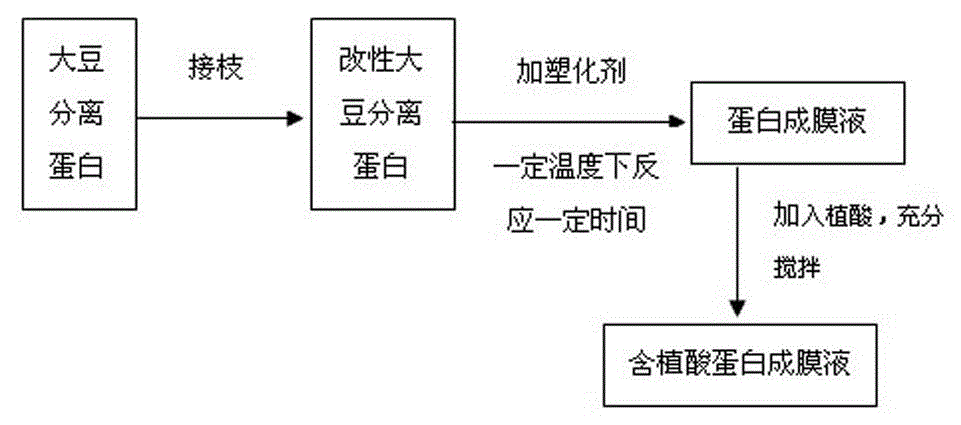

[0022] (1) Preparation of meat fresh-keeping coating solution: Weigh a certain amount of soybean protein isolate, add 36 times distilled water, and stir magnetically for a period of time in a constant temperature water bath at 25°C to disperse the protein evenly, and raise it to a reaction temperature of 75°C. Then add the dissolved chitosan with a protein ratio of 1:1, stir and react for 62 minutes, then cool down to a film-forming reaction temperature of 60°C, add glycerin with a protein weight of 1 / 2 as a plasticizer, react for 27 minutes, and cool to 25°C Add phytic acid and stir thoroughly to obtain the meat fresh-keeping coating solution.

[0023] (2) Fresh-keeping coating film for meat: Soak the meat in the tank filled with the above-mentioned coating liquid. Maximize the adsorption of coating liquid and improve the firmness of the conjunctiva.

[0024] The coating liquid obtained by using the method can make the shelf life of chilled beef (at -1°C) reach more than 38 ...

Embodiment 2

[0026] (1) Preparation of meat fresh-keeping coating liquid: Weigh a certain amount of soybean protein isolate, add 43 times distilled water, and magnetically stir in a constant temperature water bath at 25°C for a period of time to disperse the protein evenly, and raise it to a reaction temperature of 75°C. Then add the dissolved chitosan with a protein ratio of 1:1, stir and react for 78 minutes, then cool down to the film-forming reaction temperature of 60°C, add glycerin with a protein weight of 1 / 2 as a plasticizer, react for 16 minutes, and cool to 25°C Add phytic acid and stir thoroughly to obtain the meat fresh-keeping coating solution.

[0027] (2) Fresh-keeping coating film for meat: Soak the meat in the tank filled with the above-mentioned coating liquid. Maximize the adsorption of coating liquid and improve the firmness of the conjunctiva.

[0028] The coating liquid obtained by using the method can make the shelf life of chilled beef (at -1°C) reach more than 38 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com