Condensed ring aromatic saturation catalyst with strong raw material adaptability

A technology for condensed aromatic hydrocarbons and catalysts, which is applied in the field of catalysts with effective saturation of sulfur-containing or sulfur-free raw materials, and can solve the problems of poor raw material adaptability of the saturated aromatic hydrocarbons with condensed catalysts and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

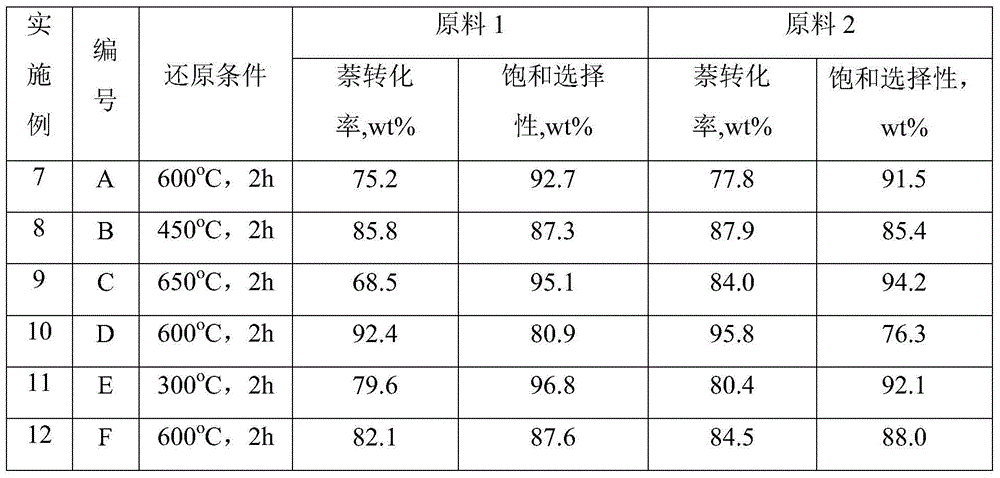

Embodiment 1

[0021] 90wt% coarse-porous silica powder and 10wt% magnesium oxide powder are used to prepare the catalyst body by rolling ball molding method, and it is ready for use after calcination at 650oC. Use the mixed solution of ammonium molybdate, nickel nitrate, diammonium hydrogen phosphate and ammonia water to impregnate with equal volume, load 6wt% Mo, 2.1wt% Ni and 5.5wt% P, dry and roast in 450oC air for 2 hours to get Catalyst A.

Embodiment 2

[0023] Zirconium oxychloride is hydrolyzed in ammonia water, treated under 120oC hydrothermal condition for 48h, filtered, washed, dried, and then prepared by kneading and extruding zirconia catalyst carrier. Catalyst B was obtained by impregnating with a mixed solution of ammonium molybdate, phosphorous acid and ammonia water, loaded with 8.2wt% Mo and 5.7wt% P, dried and calcined in air at 380oC for 2 hours.

Embodiment 3

[0025] Fully mix 90g of coarse-pored silica and 30g of boehmite, add 1:1 nitric acid and appropriate amount of water, knead and extrude, keep healthy at room temperature, dry at 120oC overnight, and roast in 550oC air atmosphere for 4 hours to obtain the catalyst carrier. The mixed solution of nickel nitrate, phosphoric acid, cerium nitrate and nitric acid was impregnated with equal volume, loaded with 7.0wt% Ni, 1.5wt% Ce and 3.2% P, dried and calcined in 450oC air for 2h to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com