Rubbish flying ash cement kiln co-treatment and water resource utilization system

A technology of co-processing and waste fly ash, applied in the direction of solid waste removal, etc., can solve the problems of vicious competition, inadequate supervision, and the inability of fly ash to be safely disposed of.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

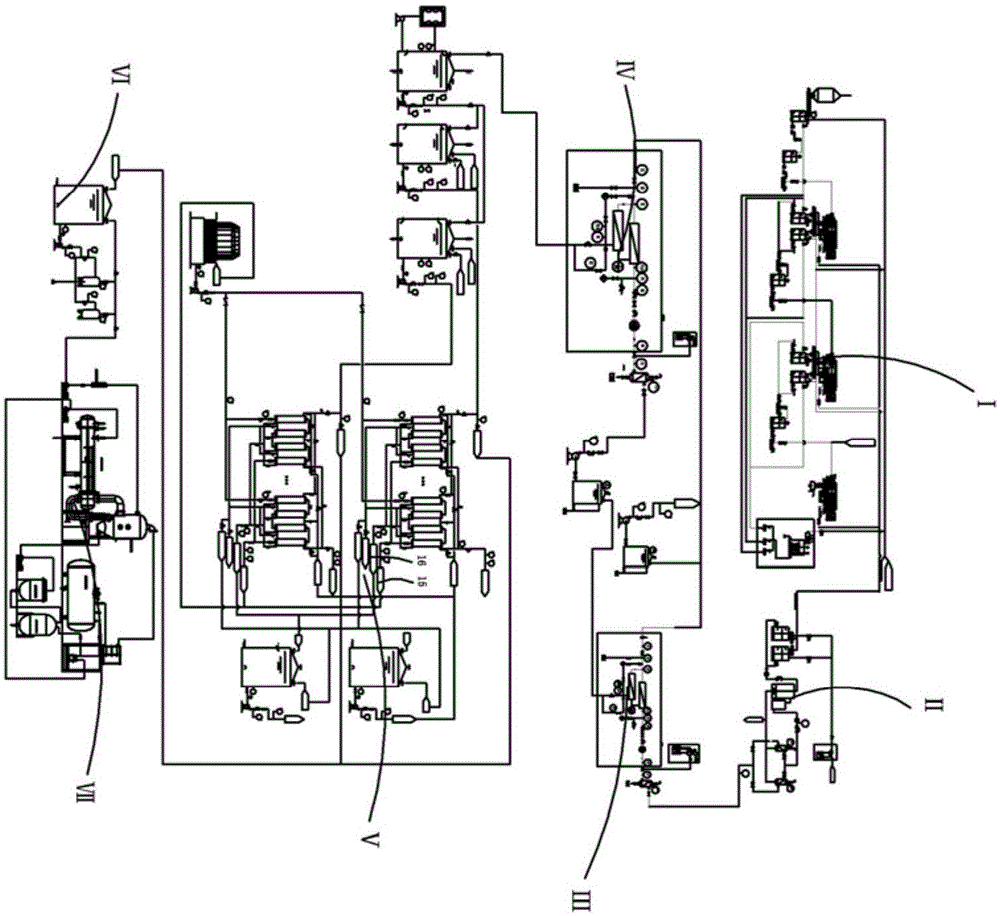

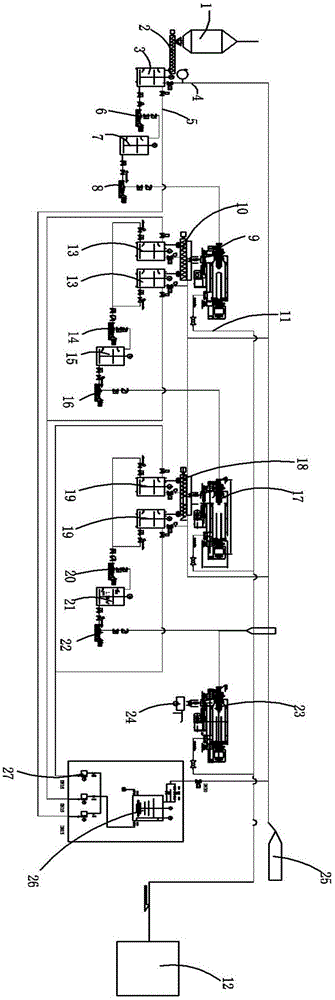

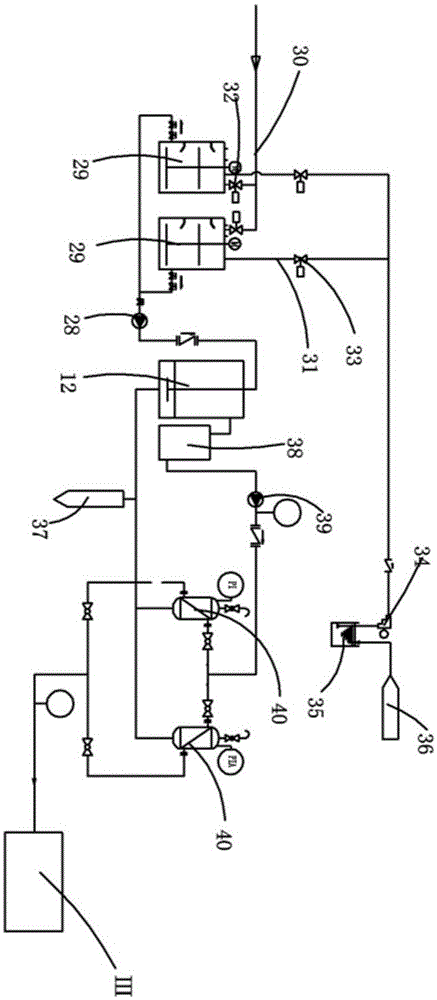

[0033] Examples, see attached Figure 1-7 , a waste fly ash cement kiln co-processing and water resource utilization system, which includes a three-stage water washing desalination system for waste incineration fly ash I, a coagulation sedimentation removal system II for heavy metals, sodium filtration III and a reverse osmosis pre-concentration system Ⅳ. Membrane distillation concentration system Ⅴ, trace miscellaneous salt removal system Ⅵ and MVR evaporative crystallization system Ⅶ; the washing water produced by the three-stage water elution and desalination system for waste incineration fly ash enters the coagulation precipitation removal system through the pipeline; coagulation The solution with a salt content rate of 1-2% obtained by the precipitation removal system enters the sodium filtration and reverse osmosis pre-concentration system; the sodium filtration and reverse osmosis pre-concentration system removes calcium and magnesium ions in the washing water, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com