Grade-A fireproof efficient homogeneous thermal self-insulation block

A self-insulating block and high-efficiency technology, applied in the field of building materials, can solve serious fires, threats to residents' lives and property, and unresolved fire prevention problems, etc., and achieve the effects of simple production process, elimination of fire hazards, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

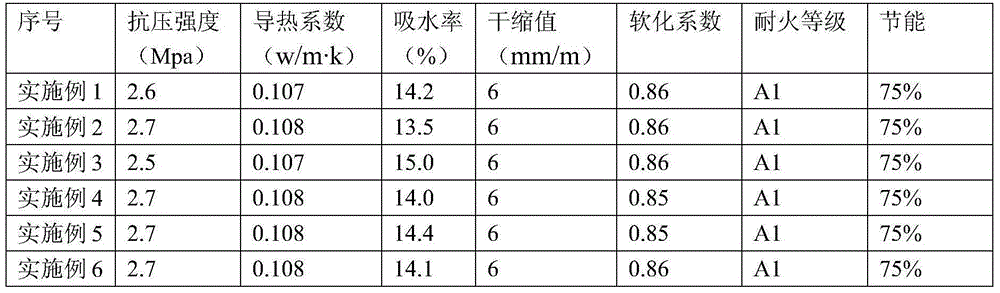

Examples

Embodiment 1

[0038] Raw material ratio (percentage by weight): 26% of ceramsite and ceramsite fragments, 3.4% of slag, 34% of perlite, 9% of perlite powder, 20% of cement, 5% of fly ash, 1.7% of silica fume, less Water agent (sodium methylene naphthalene sulfonate (MF) water reducing agent) 0.4%, ferric chloride waterproofing agent 0.3%, powder shrinkage reducing agent (METOLATP871 powder shrinkage reducing agent produced by German MUNZING chemical company) 0.2%.

[0039] The amount of water added is 50% of the total weight of the above raw materials;

[0040] The amount of perlite modifier (a mixture of silane water repellent and methyl silicate water repellent in a weight ratio of 1:10) is 5% of the above water addition.

[0041] Preparation:

[0042] (1) Weigh raw materials according to the above ratio, and then weigh the weighed ceramsite and ceramsite fragments, slag, perlite, perlite powder, cement, fly ash, silica fume, water reducing agent, waterproofing agent , Powder shrinkage ...

Embodiment 2

[0048]Raw material ratio (percentage by weight): ceramsite and ceramsite fragments 22%, slag 6%, perlite 30%, perlite powder 10%, cement 22%, fly ash 7%, silica fume 1.9%, less Water agent (sodium methylene naphthalene sulfonate (MF) water reducing agent) 0.3%, ferric chloride waterproofing agent 0.4%, powder shrinkage reducing agent (METOLATP871 powder shrinkage reducing agent produced by German MUNZING chemical company) 0.4%.

[0049] The amount of water added is 50% of the total weight of the above raw materials;

[0050] The amount of perlite modifier (a mixture of silane water repellent and methyl silicate water repellent in a weight ratio of 1:10) is 5% of the above water addition.

[0051] The preparation method is the same as in Example 1.

[0052] The size of the high-efficiency homogeneous self-insulating block of class A fireproofing in this embodiment is 390mm×270mm×190mm (length×width×height).

Embodiment 3

[0054] Raw material ratio (percentage by weight): 30% of ceramsite and ceramsite fragments, 3% of slag, 32% of perlite, 5% of perlite powder, 20% of cement, 8.2% of fly ash, 1.1% of silica fume, less Water agent (sodium methylene naphthalene sulfonate (MF) water reducing agent) 0.3%, ferric chloride waterproofing agent 0.3%, powder shrinkage reducing agent (METOLATP871 powder shrinkage reducing agent produced by German MUNZING chemical company) 0.3%.

[0055] The amount of water added is 50% of the total weight of the above raw materials;

[0056] The amount of perlite modifier (a mixture of silane water repellent and methyl silicate water repellent in a weight ratio of 1:10) is 5% of the above water addition.

[0057] The preparation method is the same as in Example 1.

[0058] The size of the high-efficiency homogeneous self-insulating block of class A fireproofing in this embodiment is 390mm×270mm×190mm (length×width×height).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com