Preparation method of modified nanometer SiO2-AA-AM copolymer

A technology of sio2-aa-am and copolymer, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high production cost of the core, difficulty in controlling the degree of regularity of the core, and poor injectability of hyperbranched polymers. To achieve the effect of optimizing viscosity increasing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 Modified nano-SiO 2 Preparation of functional monomers

[0023] The modified nano-SiO described in this embodiment 2 The functional monomer is prepared by a method comprising the following steps: (1) using nano-SiO 2 and 3-aminopropyltriethoxysilane (KH540) in anhydrous toluene solution at 80°C for 12h to obtain amino-modified nano-SiO 2 , and by controlling the amount of 3-aminopropyltriethoxysilane added to control the nano-SiO 2 The content of surface amino groups; (2) the use of excess maleic anhydride and amino-modified nano-SiO 2 Reaction to get modified nano-SiO with carbon-carbon double bond 2 functional monomer. Step (2) includes the following operations: 1. add maleic anhydride in N,N-dimethylformamide solution, stir and dissolve to obtain a mixed solution completely; 2. 2 Add N,N-dimethylformamide to the mixture and stir to obtain a dispersion; ③ Add the dispersion obtained in operation ② dropwise to the mixed solution obtained in operation...

Embodiment 2

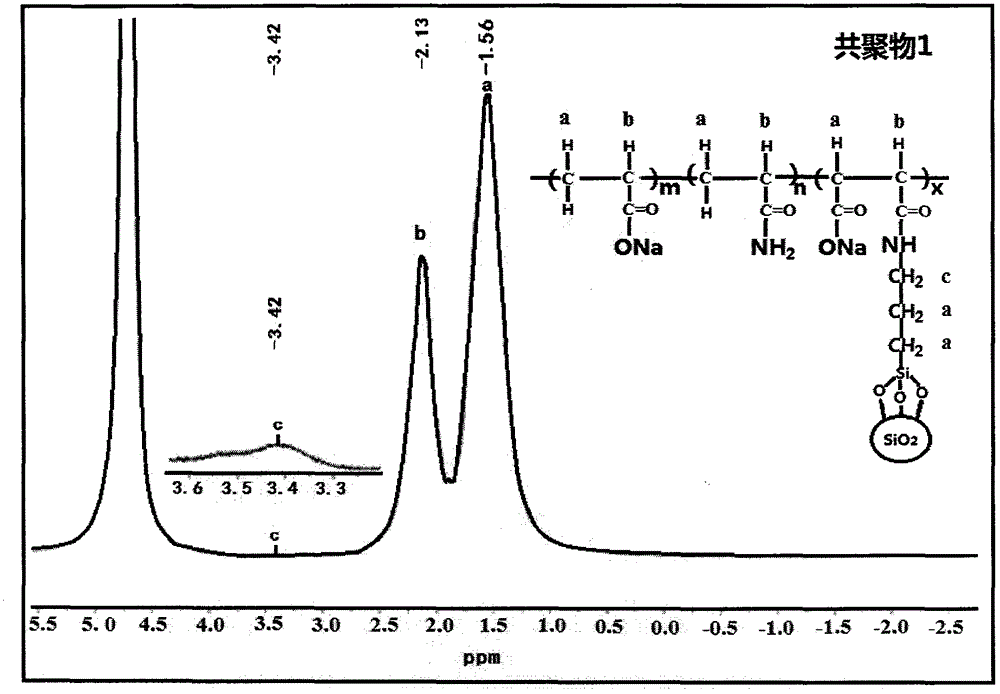

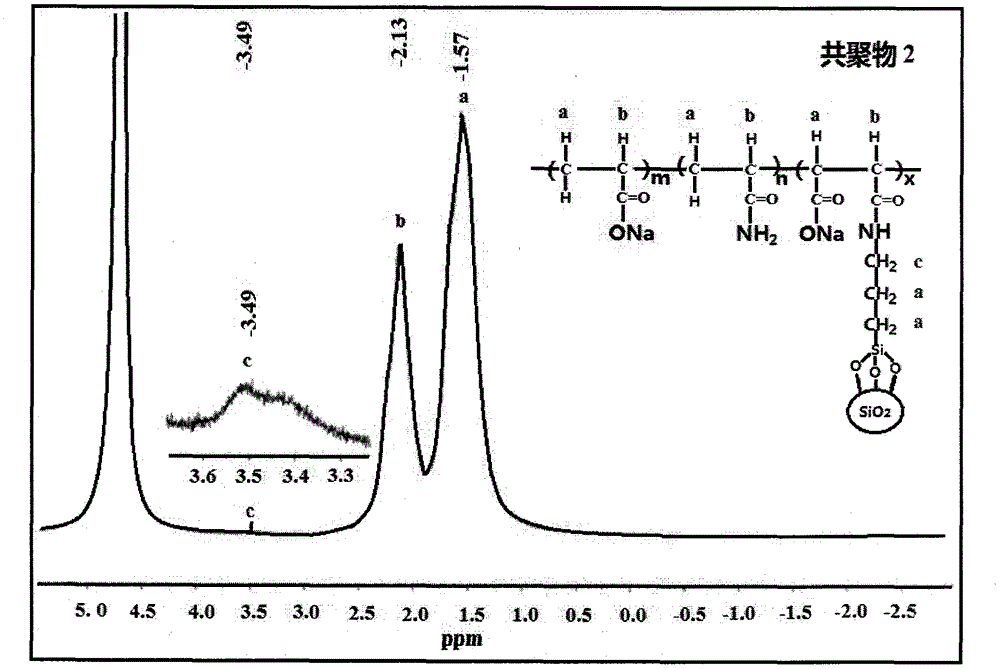

[0024] Embodiment 2 Modified nano-SiO 2 - Preparation of AA-AM copolymer

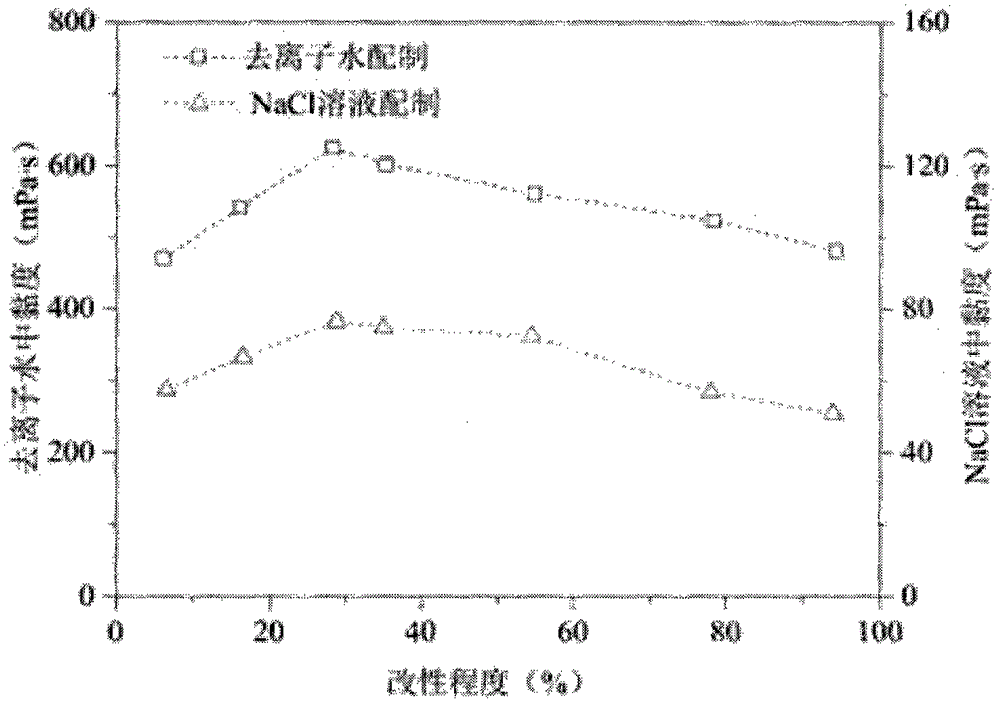

[0025] The modified nano-SiO of this embodiment 2 -The preparation method of AA-AM copolymer, comprises the following steps: (1) will modify nano-SiO 2 Mix functional monomers, acrylamide and acrylic acid, adjust the pH value to 7.0 with sodium hydroxide, add distilled water to make an aqueous solution with a total mass concentration of monomers of 25.0%; when the temperature rises to 40°C, add an initiator and pass nitrogen protection , and react at a temperature of 40.0°C; the reaction product can be washed, pulverized and dried to obtain the copolymer. Wherein, the mass of the initiator is 0.20wt% of the total mass of the monomers, and the initiator is a mixture of ammonium persulfate and sodium bisulfite, and the molar ratio of the two is 1:1. The mass ratio of acrylamide to acrylic acid in the monomer is 3.2, and the modified nano-SiO 2 The content of functional monomer is 0.50wt%. By using na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com