Method for preparing porous starch

A technology of porous starch and starch, which is applied in the field of food processing, can solve the problems of high cost and complicated process, and achieve the effect of low cost, simple process and improved oil absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

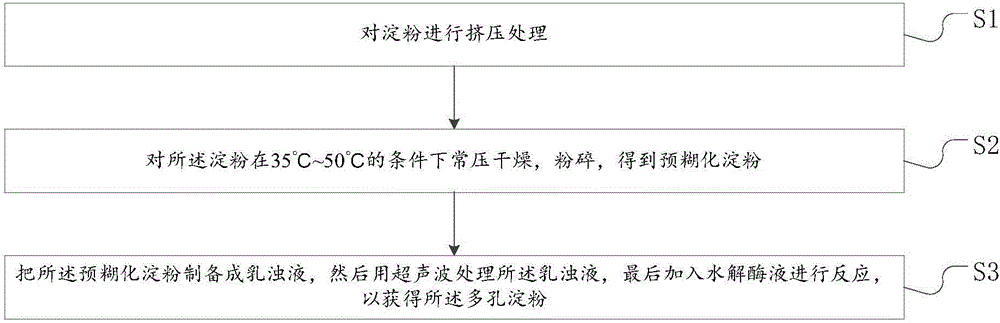

[0012] This method first uses extrusion technology to make the surface of starch granules rapidly and partially gelatinized, and the surface of starch granules after pregelatinization expands, and the structure becomes loose; and then through ultrasonic treatment, it is easier to form some concave holes on the surface of starch granules. It is beneficial for subsequent hydrolysis by glucoamylase and amylase along the position of the cavity. Promote the rapid formation of pores on the porous surface, greatly improve the pore-forming effect, and obtain porous starch with better performance, and the oil absorption capacity is greatly improved compared with untreated native starch.

[0013] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0014] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com