System and method for recycling arsenic from copper smelting smoke dust

A recovery system and copper smelting technology, applied in the field of metallurgy, can solve the problems of controlling the amount of sprayed water, uneven distribution of smoke and dust, and wet electrostatic precipitators, so as to improve the production environment and avoid arsenic pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

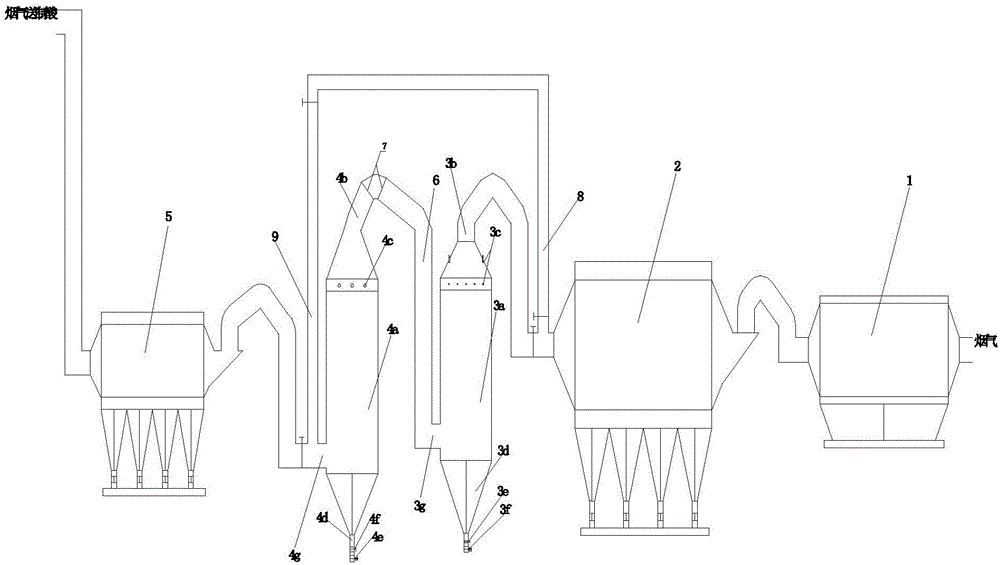

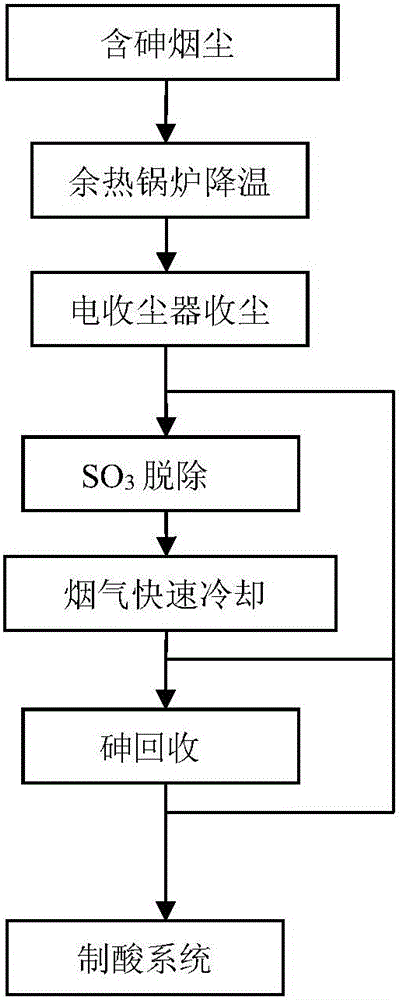

[0012] Such as figure 1 As shown, the system for recovering arsenic from copper smelting dust according to the present invention includes a waste heat boiler cooling system 1, an electric dust collector dust collection system 2, and a SO 3 Removal system, smoke and dust rapid cooling system, arsenic recovery system5. The SO 3 The removal system includes a reactor 3a in which the first smoke inlet 3b on the top communicates with the dust outlet of the electrostatic precipitator dust collection system 2, and a group of lime powder or baking soda powder injection inlets 3c are provided on the top of the reactor, and the lime powder Or the baking soda powder injection inlet 3c can be evenly distributed on the two circumferential surfaces of the cone part and the cylindrical part of the reactor 3a top around the reactor barrel wall, and the powder spraying effect will be better. The lower end of the ash hopper 3d at the bottom of the reactor is provided with a dust discharge port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com