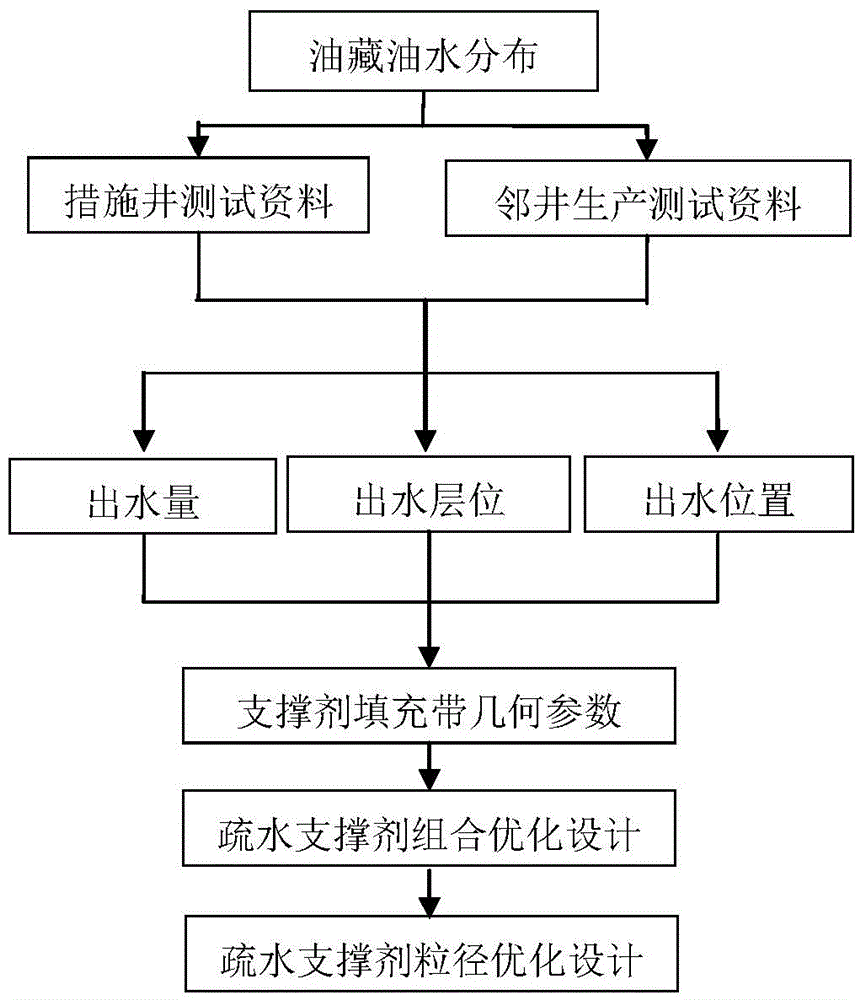

Water-control effect-enhancing fracturing method of carbonate reservoir

A carbonate reservoir and fracturing technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problem of delamination, poor return layer effect, limited acid-etched fracture length, and stress difference Small problems, to achieve the effect of increasing the fracturing scale, increasing the communication scale, and increasing the displacement pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

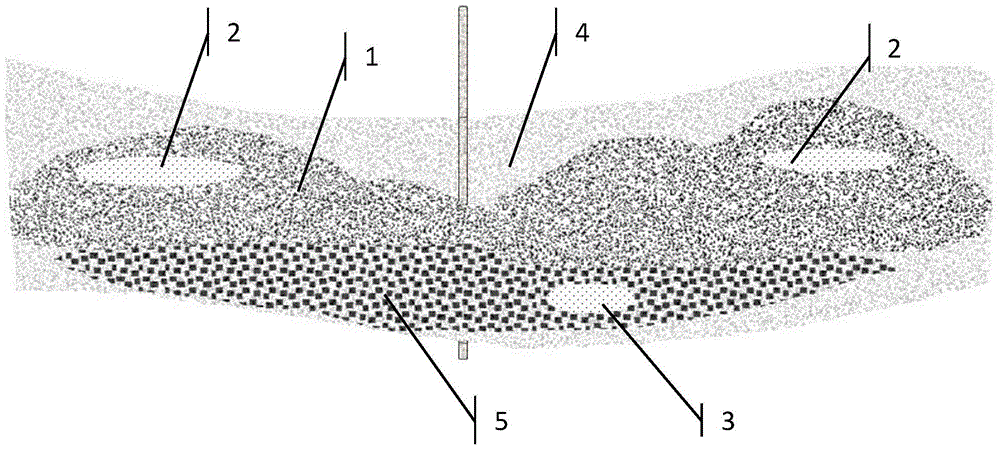

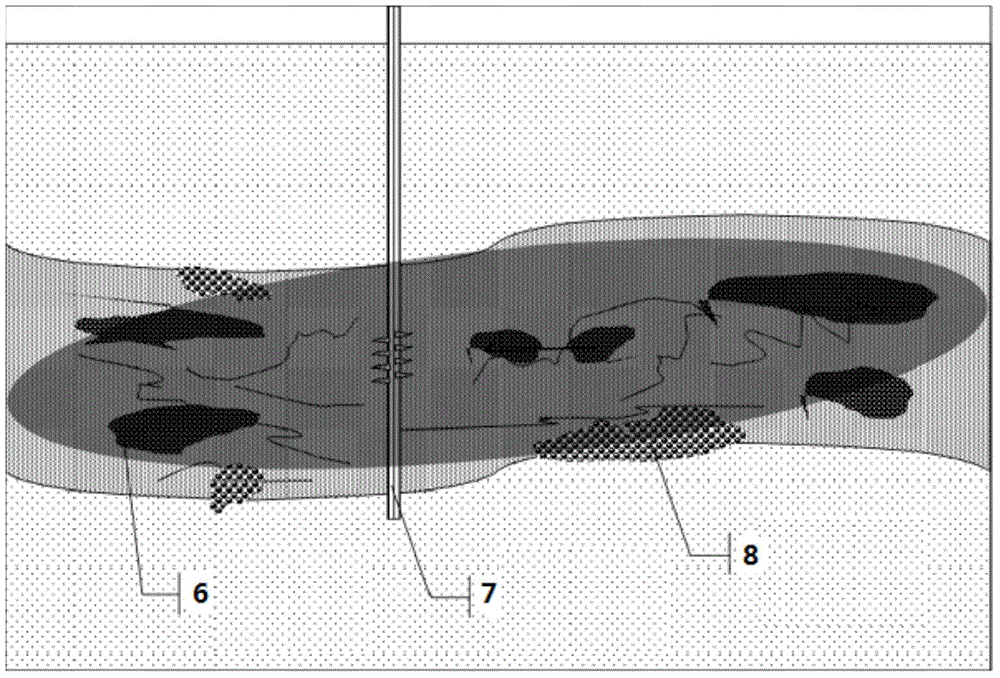

[0045] 1. Hydrophobic proppant: The proppant aggregate is water-washed ceramsite, and its particle size ranges from 0.45 to 0.90mm. The superhydrophobic film is made by curing superhydrophobic emulsion. The contact angle ranges from 85° to 135°, and the bulk density ranges from 1.8 to 2.8g / cm 3 , there are mainly three kinds, respectively, the bulk density is 1.8g / cm 3 Low-density hydrophobic proppant with a bulk density of 2.2g / cm 3 Medium-density hydrophobic proppant with a bulk density of 2.5g / cm 3 high-density hydrophobic proppant.

[0046] 3. Water-in-oil emulsified fracturing fluid: The fracturing fluid is the external phase of oil (96% of liquid hydrocarbons, 3.5% of thickeners, and 0.5% of emulsifiers), of which liquid hydrocarbons are diesel oil, kerosene, white oil, and benzene, The optimum is a stable emulsion of diesel oil and water internal phase, the volume of oil phase in fracturing fluid: the volume of water phase is 0.6:0.4;

[0047] 4. Optimum design of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com