Forming method of fin type field effect transistor

A technology of fin field effect transistors and fins, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve the problem of excessive contact resistance of fin field effect transistors and the inability to form metal contact layers on the side walls of fins, etc. problem, to achieve the effect of improved stability, reduced etching rate, and improved response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

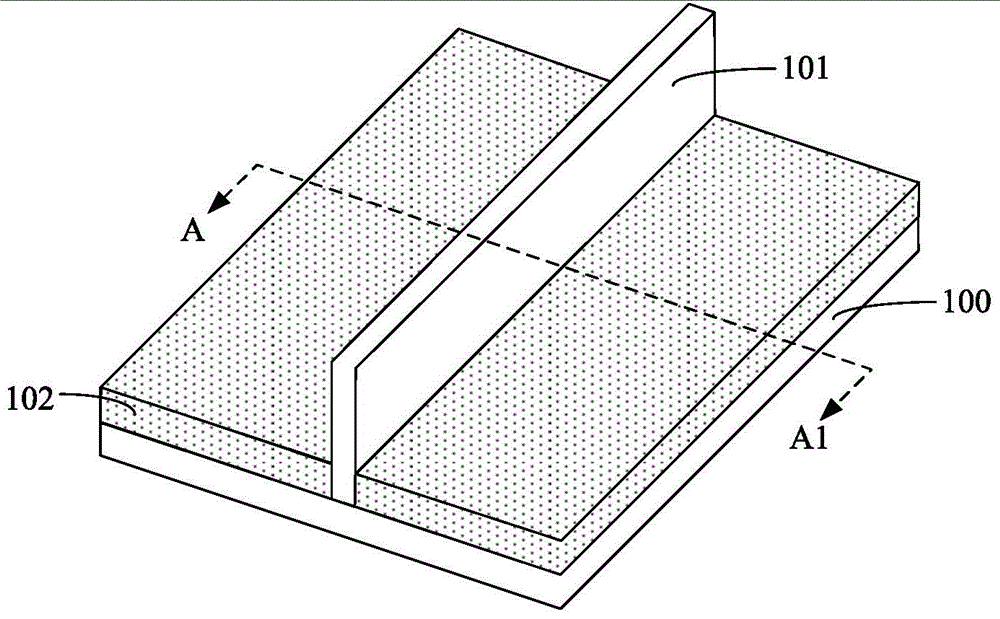

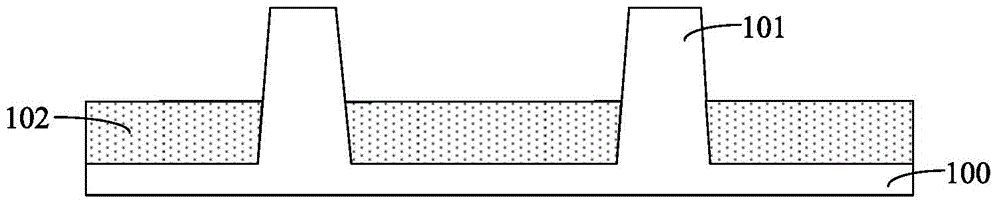

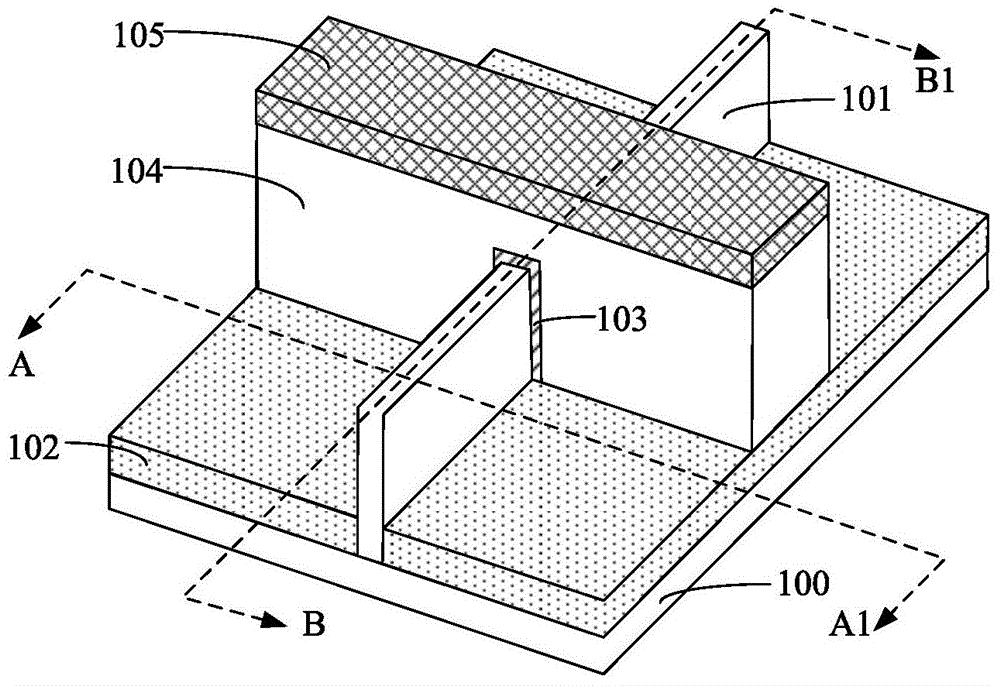

[0032] It can be seen from the background technology that the electrical performance of the FinFET provided by the prior art needs to be improved. For example, the contact resistance of the FinFET is relatively large, the response rate of the FinFET is low, and the FinFET Weak ability to electrically connect with other devices.

[0033] After research, it is found that the reason for the large contact resistance of the FinFET and the weak ability to electrically connect with other devices is: in order to reduce the contact resistance of the FinFET and make the FinFET electrically connected to other devices. Connection, usually form a metal contact layer in the source and drain regions of the FinFET, for example, the material of the metal contact layer is NiSi, in order to reduce the contact resistance of the FinFET and improve the response speed of the FinFET , and the fin field effect transistor can also be electrically connected to other devices through the metal contact lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com