Three-dimensional electrode photoelectric microbial fuel cell reactor, and marsh gas quality and effectiveness improving method

A fuel cell, three-dimensional electrode technology, applied in biochemical fuel cells, waste fuels, chemical instruments and methods, etc., can solve the problems of insufficient degradation of organic matter, low power generation efficiency, low biomass energy utilization efficiency, etc. The effect of catalytic efficiency, improving efficiency and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

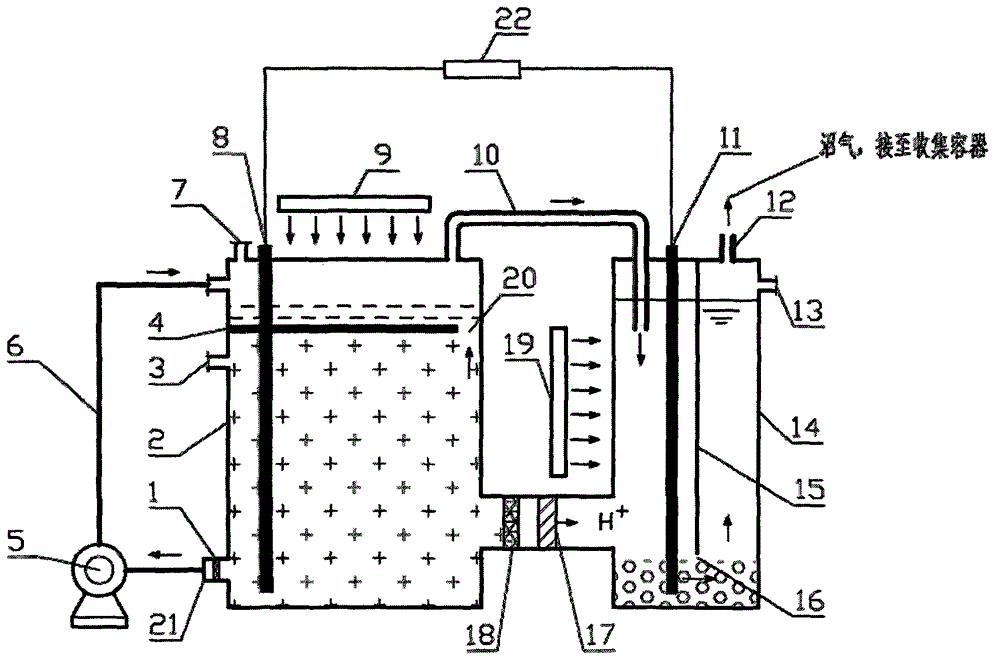

[0055] A three-dimensional electrode photoelectric microbial fuel cell reactor, comprising an anode chamber 2 and a cathode chamber 14 separated by a proton exchange membrane 17, an anode 8 is arranged in the anode chamber, a cathode 11 is arranged in the cathode chamber, and the anode and the cathode are externally connected to variable resistors by wires 22 connected, the anode chamber is divided into upper and lower parts by the photocatalytic plate 4, the upper part is the photocatalytic area, the lower part is the microbial anaerobic digestion area, the cathode chamber is divided into left and right parts by the partition 15, and the bottom of the partition is opened Vent 16;

[0056] The ultraviolet light sources 9 and 19 are controlled by a switch, and there are two places respectively located above the anode chamber and on the side of the cathode chamber. As a preference, the top of the anode chamber and the side of the cathode chamber irradiated by the ultraviolet ligh...

Embodiment 2

[0072] A biogas quality-enhancing and efficiency-enhancing method using three-dimensional electrode photoelectric microbial fuel cell technology (using straw and poultry manure as raw materials):

[0073] First, biofilm formation is carried out without ultraviolet light irradiation: turn off the ultraviolet light sources 9 and 19, add the domesticated activated sludge solution or the special microbial bacterial solution cultivated for refractory organic matter into the microbial anode chamber 2, and make it Immerse the biofilm carrier (granular biochar with a particle size of 3 to 5 mm), and circulate in the microbial anode chamber 2 through the circulation pump 5. After inoculation by adsorption, a mature biofilm will be formed after 5 to 10 days, and excess active pollution will be discharged. Mud or liquid.

[0074] After the biofilm is formed, take the air-dried agricultural and forestry waste straw and chop it to about 3cm, and at the same time take fresh livestock and po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com