Making method for reducing content of acrylamide in baked food

A production method and technology of acrylamide, which is applied in the production field of reducing the content of acrylamide in baked food, to achieve the effect of short time, low temperature and enhanced nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 9~12

[0036] Embodiment 9~12 the research of combined process to reduce acrylamide content

[0037] Recipe: 100g flour, 120g eggs, 90g white sugar, 3g cake oil, 1.5g baking powder.

[0038] Processing technology: According to the formula quantity, first mix the eggs and white sugar slowly, then add the cake oil and whip quickly until the material liquid presents a white foamy structure, and the egg paste is obtained;

[0039] Mix the flour and baking powder evenly, sieve into the custard, stir well at a slow speed to get the batter;

[0040] Inject the batter into the mold pre-coated with soybean oil, the injection volume accounts for 2 / 3 of the mold volume, shake the mold for 10 seconds quickly, and discharge the air between the batter and the mold;

[0041] Put the mold with the batter in a microwave oven with a frequency of 915MHz to mature (the curing time is set to 60s, 90s, 120s, 150s respectively), and then put it in an oven for coloring (200°C, 3min) to obtain a cake produc...

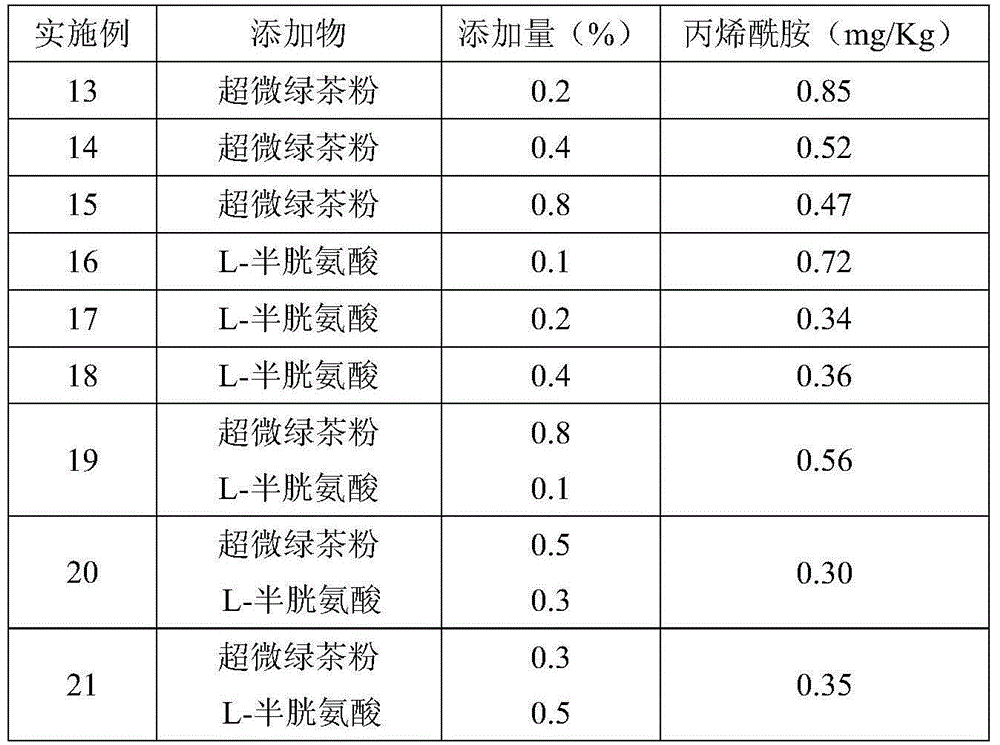

Embodiment 13~20

[0047] Influence of antioxidant components on the formation of acrylamide in the combined process of Examples 13-20

[0048] Recipe: 100g flour, 120g eggs, 90g white sugar, 3g cake oil, 1.5g baking powder.

[0049] Antioxidant ingredients: superfine green tea powder and / or L-cysteine. The amount of antioxidant ingredients added is calculated based on the total weight of the formula ingredients (flour, eggs, white sugar, cake oil and baking powder). For the specific added amount, see Table 3. Superfine green tea powder was purchased from Zhejiang Minghuang Natural Food Development Co., Ltd.

[0050] Processing technology: according to the formula quantity, first beat the eggs and sugar slowly and mix well, then add cake oil and whip quickly until the material liquid presents a white foamy structure to obtain egg paste;

[0051] Mix the flour, baking powder, superfine green tea powder and / or L-cysteine evenly, sieve into the custard, stir well at a slow speed to get the batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com