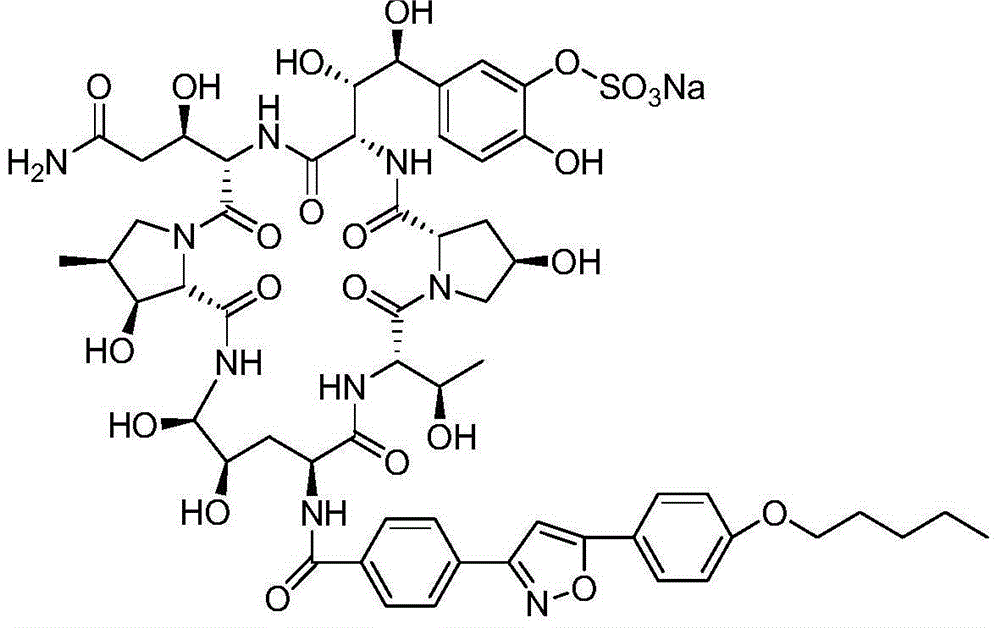

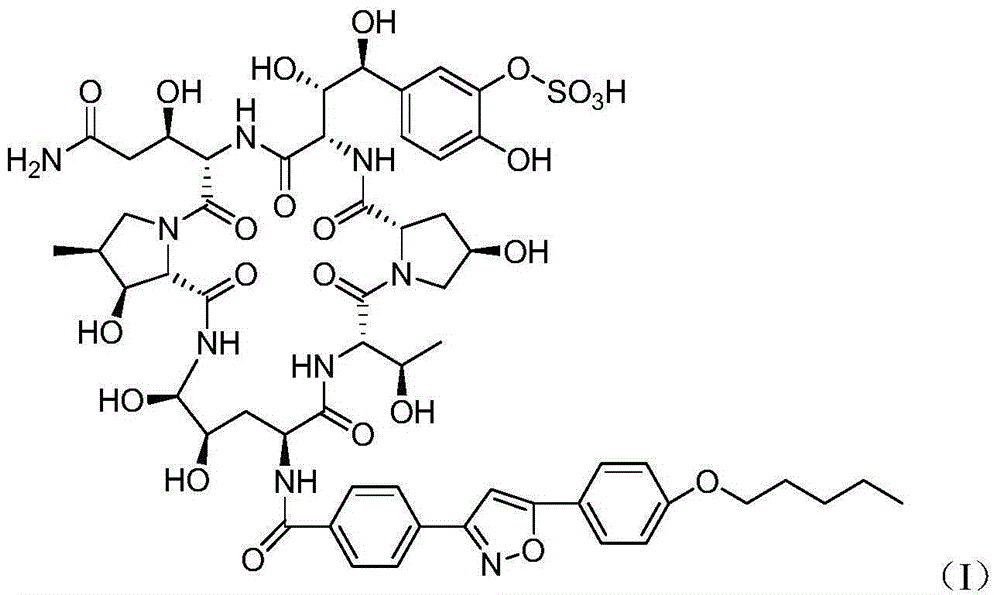

Freeze-dried composition containing micafungin and preparation method of freeze-dried composition

A technology of micafungin and a composition, applied in the field of pharmaceutical preparations, can solve the problems of increasing the difficulty of quality control, the risk of medication, and the types of excipients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

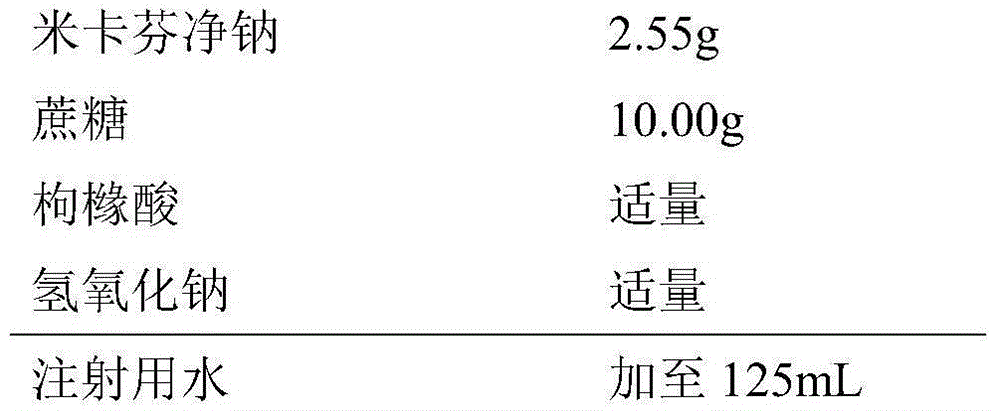

Embodiment 1

[0040]

[0041]Preparation method: Dissolve sucrose in 100ml of cooled water for injection at room temperature, add about 0.1g of citric acid and an appropriate amount of 0.1M sodium hydroxide solution to adjust the pH of the solution to 5-6, add micafungin sodium and stir until Dissolve, add water for injection to 125ml; filter the obtained medicinal solution through a 0.20μm sterile filter membrane, pack into 50 10ml vials, each 2.5ml, and half stopper. Place the vial containing the medicinal liquid in a tray in the cold trap of an ordinary lyophilizer for cooling. The freezing liquid in the tray is 60% ethylene glycol solution, and the liquid level of the freezing liquid is flush with the medicinal liquid level in the vial. When the medicinal liquid When the temperature is cooled to about 0°C, start the multi-frequency ultrasonic cell disruptor to perform pulse ultrasonic treatment on the frozen liquid. The ultrasonic frequency is 25kHz, the electric power is 150W, and th...

Embodiment 2

[0043]

[0044]

[0045] Preparation method: Dissolve sucrose in 100ml of cooled water for injection at room temperature, add about 0.1g of citric acid and an appropriate amount of 0.1M sodium hydroxide solution to adjust the pH of the solution to 5-6, add micafungin sodium and stir until Dissolve, add water for injection to 125ml; filter the obtained medicinal solution through a 0.20μm sterile filter membrane, pack into 50 10ml vials, each 2.5ml, and half stopper. Place the vials containing the medicinal solution in a tray in the cold trap of an ordinary lyophilizer to freeze. The freezing liquid in the tray is 60% ethylene glycol solution. When the temperature is cooled to about -2°C, start the multi-frequency ultrasonic cell disruptor to perform pulse ultrasonic treatment on the frozen liquid, with an ultrasonic frequency of 30 kHz, an electric power of 100 W, and a duty ratio of 4:1 until the liquid freezes. Then, put the vial into a freeze-drying box, lower the temp...

Embodiment 3

[0047]

[0048] Preparation method: Dissolve sucrose in 100ml of cooled water for injection at room temperature, add about 0.1g of citric acid and an appropriate amount of 0.1M sodium hydroxide solution to adjust the pH of the solution to 5-6, add micafungin sodium and stir until Dissolve, add water for injection to 125ml; filter the obtained medicinal solution through a 0.20μm sterile filter membrane, pack into 50 10ml vials, each 2.5ml, and half stopper. Place the vials containing the medicinal solution in a tray in the cold trap of an ordinary lyophilizer to freeze. The freezing liquid in the tray is 60% ethylene glycol solution. When the temperature is cooled to about -5°C, start the multi-frequency ultrasonic cell disruptor to perform pulse ultrasonic treatment on the frozen liquid, with an ultrasonic frequency of 40kHz, an electric power of 80W, and a duty ratio of 5:1 until the liquid freezes. Then, put the vial into a freeze-drying box, lower the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com