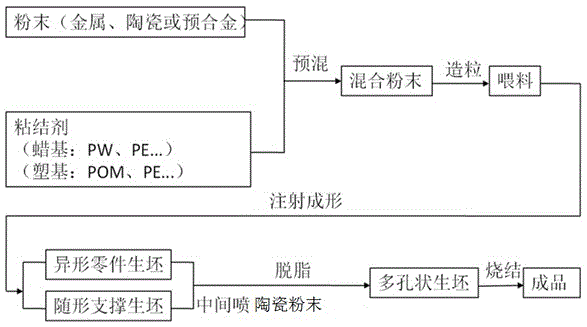

Method for preparing special-shaped complex part through powder injection molding technology

A technology of powder injection molding and complex parts, which is applied in the manufacture of tools, ceramic molding machines, etc., can solve the problems of deformation, collapse and fracture of parts, and achieve the effect of high precision, better quality and complex appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1Cp-Ti special-shaped complex parts

[0032] S1. Mixing and granulation: mix 55% Cp-Ti powder with volume fraction of 45% binder (the mass ratio of binder is paraffin:polyethylene:stearic acid=36:60:4) Blend in the mill at 160°C for 2 hours; then pass through the granulator to form granular feed;

[0033] S2. Injection molding: inject the feed material obtained by mixing into the mold of special-shaped complex parts and conformal support parts through the injection machine, the injection temperature is 160 ° C, the injection pressure is 110 MPa, and the injection mold temperature is 80 ° C to obtain the green body of special-shaped complex parts and Conformal support parts green body;

[0034] S3. Degreasing and sintering: degrease the green body of special-shaped complex parts and the green body of conformal support parts by combining solvent degreasing method and thermal degreasing method, first degrease with n-hexane solution at 60 °C f...

Embodiment 2

[0035] The preparation of embodiment 2 Cp-Ti special-shaped complex parts

[0036] S1. Mixing and granulation: mix 55% Cp-Ti powder with volume fraction of 45% binder (the mass ratio of binder is paraffin:polyethylene:stearic acid=36:60:4) Blend in the mill at 160°C for 2 hours; then pass through the granulator to form granular feed;

[0037] S2. Injection molding: inject the feed material obtained by mixing into the mold of special-shaped complex parts and conformal support parts through the injection machine, the injection temperature is 160 ° C, the injection pressure is 110 MPa, and the injection mold temperature is 80 ° C to obtain the green body of special-shaped complex parts and Conformal support parts green body;

[0038] S3. Degreasing and sintering: Degrease the green body of special-shaped complex parts and conformal support parts by combining solvent degreasing method and thermal degreasing method, first degrease with n-hexane solution at 50 °C for 24 hours, and ...

Embodiment 3316

[0039] Example 3316 stainless steel special-shaped complex parts injection molding

[0040] S1. Mixing and granulation: 316 stainless steel powder with a volume fraction of 62%, and a binder with a volume fraction of 38% (the mass ratio of the binder is polyoxymethylene:polyethylene:paraffin:stearic acid=75:10:10: 5) Blend in the mixer at 190°C for 2 hours; then pass through the granulator to form granular feed;

[0041] S2. Injection molding: inject the feed material obtained by mixing into the mold of special-shaped complex parts and conformal support parts through the injection machine, the injection temperature is 190 °C, the injection pressure is 160 MPa, and the injection mold temperature is 120 °C to obtain the green body of special-shaped complex parts and Conformal support parts green body;

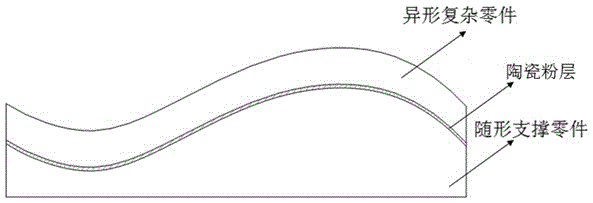

[0042]S3. Degreasing and sintering: Spray a layer of 2μm Al2O3 powder on the contact surface of the conformal support part green body and the special-shaped complex part green b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com