Soil phosphorus activator and preparation method therefor

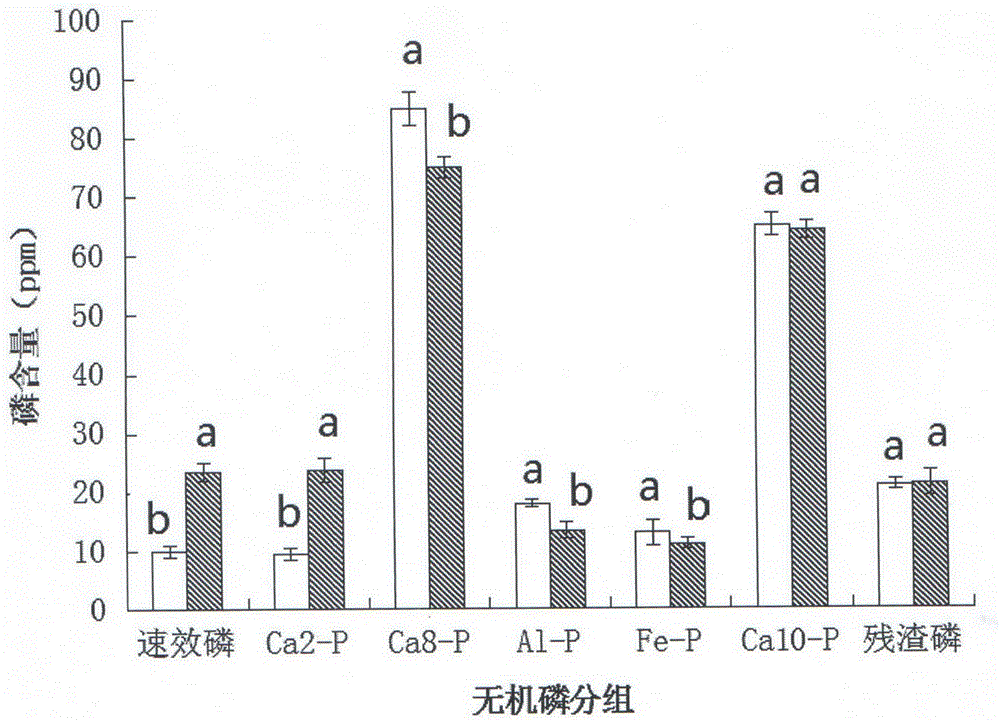

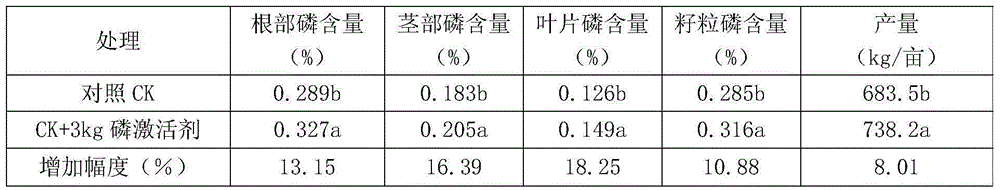

A soil phosphorus and activator technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of low phosphorus fertilizer efficiency and long aftereffect of phosphorus fertilizer, and achieve the goal of increasing crop yield, root system vitality, and absorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] a. Crushing each raw material urea phosphate, fulvic acid, sodium alginate, oxalic acid, citric acid, maleic acid and sodium nitrophenolate through a pulverizer, and passing through a 150-mesh sieve;

[0014] b. According to the parts by weight of raw materials: 32 parts of urea phosphate, 42 parts of fulvic acid, 8 parts of sodium alginate, 8 parts of oxalic acid, 4.9 parts of citric acid, 5 parts of maleic acid, and 0.1 part of sodium nitrophenolate are mixed evenly. Bagging and packaging are complete.

Embodiment 2

[0016] a. Crushing each raw material urea phosphate, fulvic acid, sodium alginate, oxalic acid, citric acid, maleic acid and sodium nitrophenolate through a pulverizer, and passing through a 150-mesh sieve;

[0017] b. According to the parts by weight of raw materials: 39 parts of urea phosphate, 40 parts of fulvic acid, 7 parts of sodium alginate, 6 parts of oxalic acid, 3.9 parts of citric acid, 4 parts of maleic acid, and 0.1 part of sodium nitrophenolate are mixed evenly. Bagging and packaging are complete.

Embodiment 3

[0019] a, each raw material urea phosphate, fulvic acid, sodium alginate, oxalic acid, citric acid, maleic acid, compound sodium nitrophenolate is crushed through a pulverizer, and crosses a 150-mesh sieve;

[0020] b. According to the parts by weight of raw materials: 35 parts of urea phosphate, 40 parts of fulvic acid, 8 parts of sodium alginate, 7 parts of oxalic acid, 4.9 parts of citric acid, 5 parts of maleic acid, and 0.1 part of sodium nitrophenolate are mixed evenly. Bagging and packaging are complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com