Preparation method of high-performance organic fertilizer

An organic fertilizer and high-performance technology, applied in the preparation of organic fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve the problems of excessive fertilization, loss of nitrogen and phosphorus in farmland, low absorption and utilization efficiency, and unregulated application amount, etc. The ability to maintain fertilizer and supply fertilizer, improve fertilizer utilization rate, and improve the effect of soil compaction and salinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

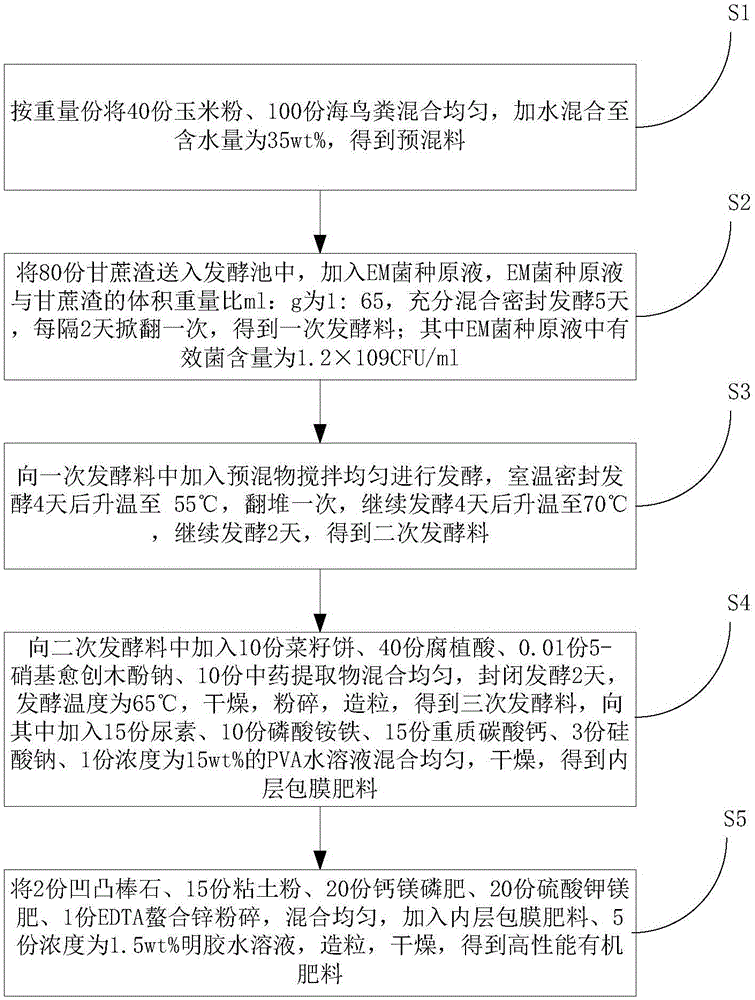

[0028] refer to figure 1 , a preparation method of a high-performance organic fertilizer, comprising the steps of:

[0029] S1. Mix 40 parts of corn flour and 100 parts of guano uniformly in parts by weight, add water and mix until the water content is 35wt%, to obtain a premix;

[0030] S2. Send 80 parts of bagasse into the fermentation tank, add EM strain stock solution, the volume-to-weight ratio ml:g of EM strain stock solution and bagasse is 1:65, fully mix and seal fermentation for 5 days, and lift it every 2 days Turn over once to obtain a fermented material; wherein the effective bacteria content in the stock solution of EM strains is 1.2×109CFU / ml;

[0031] S3. Add the premix to the primary fermentation material and stir evenly to carry out fermentation. After 4 days of sealed fermentation at room temperature, the temperature is raised to 55° C., turned once, and the fermentation is continued for 4 days, then the temperature is raised to 70° C., and the fermentation ...

Embodiment 2

[0035] A preparation method of a high-performance organic fertilizer, comprising the steps of:

[0036] S1. Mix 80 parts of corn flour and 50 parts of guano uniformly in parts by weight, add water and mix until the water content is 45wt%, to obtain a premix;

[0037] S2. Send 50 parts of bagasse into the fermentation tank, add EM strain stock solution, the volume-to-weight ratio ml:g of EM strain stock solution and bagasse is 1:40, fully mix and seal and ferment for 10 days, and lift it every other day Turn over once to obtain a fermented material; wherein the effective bacteria content in the stock solution of EM strains is 1.8×109CFU / ml;

[0038] S3. Add the premix to the primary fermentation material and stir evenly to carry out fermentation. After 2 days of sealed fermentation at room temperature, the temperature is raised to 65° C., turned once, and the fermentation is continued for 2 days, then the temperature is raised to 75° C., and the fermentation is continued for 1 da...

Embodiment 3

[0042] A preparation method of a high-performance organic fertilizer, comprising the steps of:

[0043] S1. Mix 60 parts of corn flour and 95 parts of guano uniformly in parts by weight, add water and mix until the water content is 40wt%, to obtain a premix;

[0044] S2. Send 74 parts of bagasse into the fermentation tank, add EM strain stock solution, the volume-to-weight ratio ml:g of EM strain stock solution and bagasse is 1:60, fully mix and seal and ferment for 8 days, and lift it every other day Turn over once to obtain a fermented material; wherein the effective bacteria content in the stock solution of EM strains is 1.6×109CFU / ml;

[0045] S3. Add the premix to the primary fermentation material and stir evenly for fermentation. After 2-4 days of sealed fermentation at room temperature, the temperature is raised to 60°C, turned once, and the fermentation is continued for 4 days, then the temperature is raised to 71°C, and the fermentation is continued for 2 days to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com