Flame-retardant monomer, preparation method and application thereof

A kind of technology of flame retardant monomer and reed fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

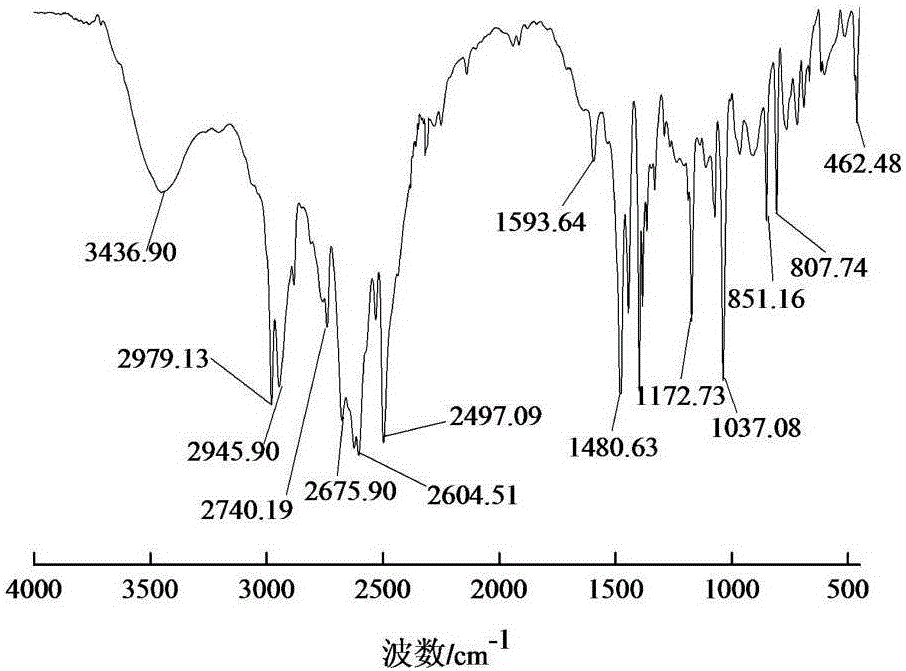

Embodiment 1

[0029] Synthetic method of new phosphorus-containing, nitrogen-free halogen-free flame retardant monomer PPP: Weigh 4.3g of anhydrous piperazine, 10.50g of phenyl phosphate dichloride, 40ml of acetonitrile and 10.1g of triethylamine, and anhydrous piperazine, tri Ethylamine was added into a three-necked flask equipped with a magnetic stirring and reflux condensing device, and the acetonitrile solution of phenyl phosphate dichloride was slowly dropped into the three-necked flask at 25°C, and reacted at 50°C for 10 hours. After the reaction is over, put in an appropriate amount of acetone, cool, stand still, separate the liquid, leave a layer of white solution, then wash with acetone, acetonitrile and water several times in sequence, filter with suction, and dry in a blast drying oven at 80°C for 4 hours , to obtain a pale yellow powder product (PPP).

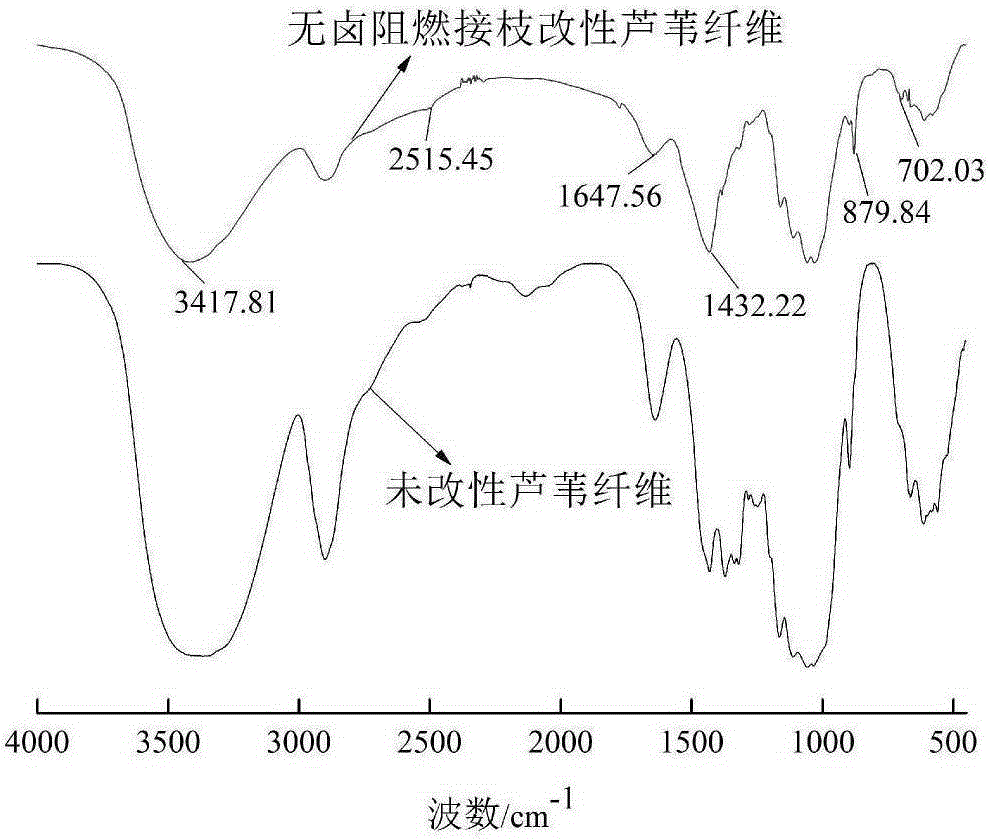

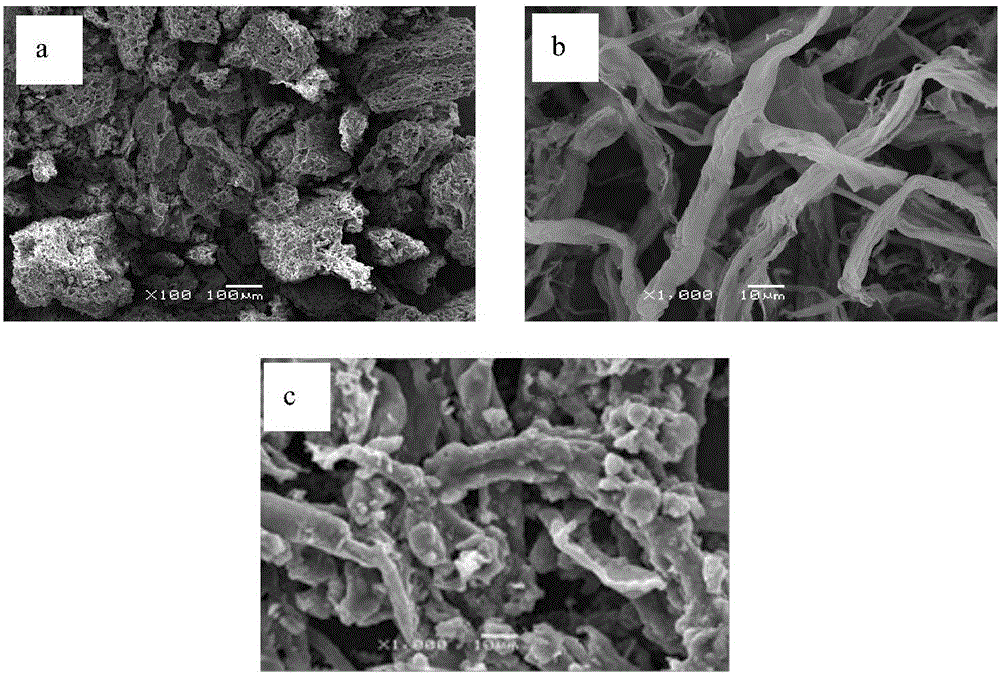

[0030] The preparation method of halogen-free flame-retardant grafted modified reed fiber: first, dry the unmodified reed fiber...

Embodiment 2

[0033] Synthetic method of new phosphorus-containing, nitrogen-free halogen-free flame retardant monomer PPP: Weigh 4.3g of anhydrous piperazine, 10.50g of phenyl phosphate dichloride, 40ml of acetonitrile and 10.1g of triethylamine, and anhydrous piperazine, tri Ethylamine was added into a three-necked flask equipped with a magnetic stirring and reflux condensing device, and the acetonitrile solution of phenyl phosphate dichloride was slowly dropped into the three-necked flask at 25°C, and reacted at 50°C for 10 hours. After the reaction is over, put in an appropriate amount of acetone, cool, stand still, separate the liquid, leave a layer of white solution, then wash with acetone, acetonitrile and water several times in sequence, filter with suction, and dry in a blast drying oven at 80°C for 4 hours , to obtain a pale yellow powder product (PPP).

[0034] The preparation method of halogen-free flame-retardant grafted modified reed fiber: first, dry the unmodified reed fiber...

Embodiment 3

[0037]Synthetic method of new phosphorus-containing, nitrogen-free halogen-free flame retardant monomer PPP: Weigh 4.3g of anhydrous piperazine, 10.50g of phenyl phosphate dichloride, 40ml of acetonitrile and 10.1g of triethylamine, and anhydrous piperazine, tri Ethylamine was added into a three-necked flask equipped with a magnetic stirring and reflux condensing device, and the acetonitrile solution of phenyl phosphate dichloride was slowly dropped into the three-necked flask at 25°C, and reacted at 50°C for 10 hours. After the reaction is over, put in an appropriate amount of acetone, cool, stand still, separate the liquid, leave a layer of white solution, then wash with acetone, acetonitrile and water several times in sequence, filter with suction, and dry in a blast drying oven at 80°C for 4 hours , to obtain a pale yellow powder product (PPP).

[0038] The preparation method of halogen-free flame-retardant grafted modified reed fiber: first, dry the unmodified reed fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com