Simple and universal method for preparation of superhydrophobic material

A super-hydrophobic and universal technology, applied in the field of preparation of simple super-hydrophobic materials, can solve the problems of super-hydrophobic materials such as complex process, expensive equipment, high cost, etc., and achieve the effect of simple and fast preparation method, low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Sponge is used as the matrix of superhydrophobic material.

[0028] Put the sponge under the irradiation of ozone and ultraviolet light for 0.5h to make the surface of the sponge hydroxylated, take out the sponge and place it in CH with a volume fraction of 0.1%. 3 SiCl 3 Soak in the n-hexane solution of 1h, and the humidity of the external environment is controlled at 30%. After the completion, the sponge is taken out, placed in an oven, and dried at a temperature of 50°C to obtain a sponge with superhydrophobic properties.

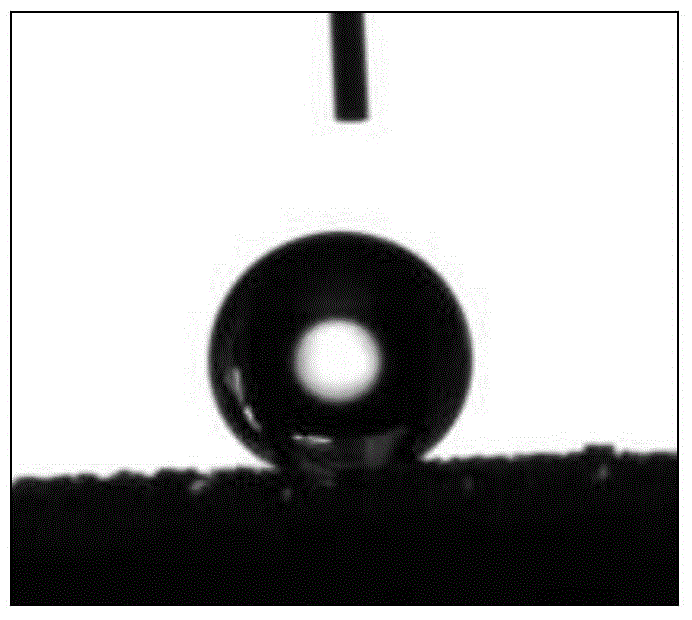

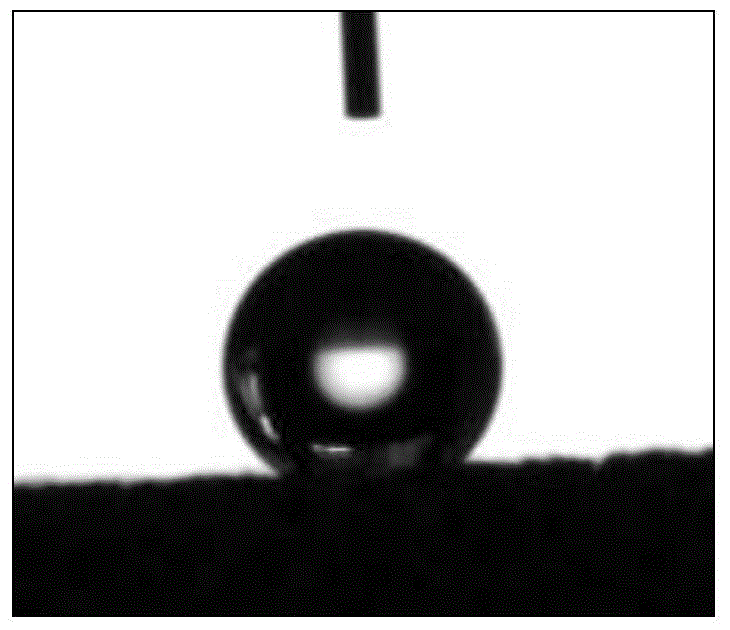

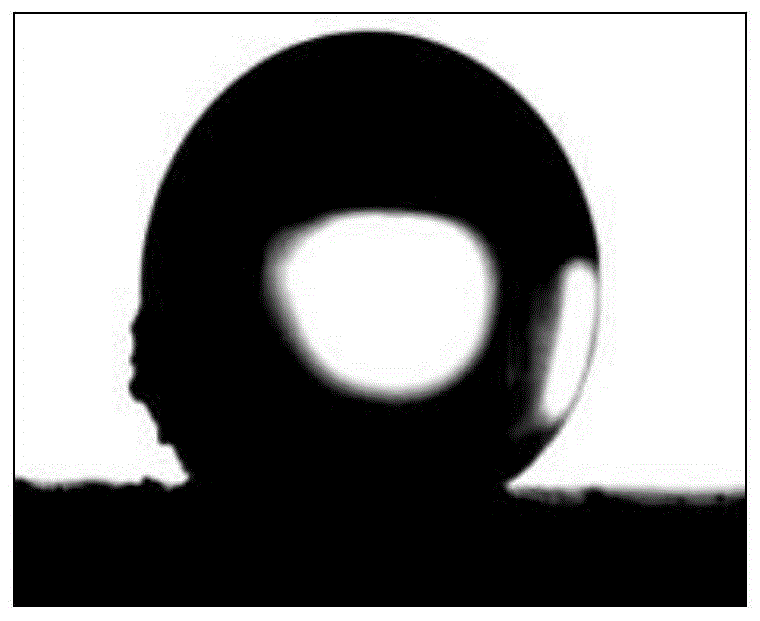

[0029] The properties of superhydrophobic materials were tested and characterized by using contact angle tester, scanning electron microscope, Fourier transform infrared spectroscopy and other instruments and equipment. Contact angle photos of superhydrophobic sponges as figure 1 Shown, the sponge that proves the superhydrophobic property of above-mentioned preparation has superhydrophobic property really; The scanning electron micrograph of sup...

Embodiment 2

[0031] Sponge is used as the matrix of superhydrophobic material.

[0032] Put the sponge under the irradiation of ozone and ultraviolet light for 1 hour to make the surface of the sponge hydroxylated, take out the sponge and place it in CH with a volume fraction of 0.5%. 3 SiCl 3 Soak in the n-hexane solution of 1h, and the humidity of the external environment is controlled at 30%. After the completion, the sponge is taken out, placed in an oven, and dried at a temperature of 60°C to obtain a sponge with superhydrophobic properties.

[0033] The properties of superhydrophobic materials were tested and characterized by using contact angle tester, scanning electron microscope, Fourier transform infrared spectroscopy and other instruments and equipment. The characterization pictures / photos are the same or similar to those in Example 1, indicating that the superhydrophobic sponge of this example does have superhydrophobic properties.

Embodiment 3

[0035] The foamed nickel metal material is used as the matrix of the superhydrophobic material.

[0036] Put the foamed nickel metal material under the irradiation of ozone and ultraviolet light for 0.5h to make the surface of the foamed nickel metal material hydroxylated, take out the foamed nickel metal material and place it in CH with a volume fraction of 0.5%. 3 SiCl 3 Soak in the normal hexane solution of 1h, the humidity of the external environment is controlled at 30%, after completion, take out the foamed nickel metal material, place it in an oven, and dry it at a temperature of 120°C to obtain a foamed nickel with superhydrophobic properties. metallic material.

[0037] Contact angle photos of superhydrophobic nickel foam as figure 2 , SEM images of superhydrophobic nickel foam as Figure 7 , indicating that the superhydrophobic nickel metal foam material of this embodiment does have superhydrophobic properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com