In-situ synthesis TiB2/TiC reinforced Ti2Ni/TiNi biphase metal compound base composite coating and preparation method

A metal compound, in-situ synthesis technology, applied in the direction of metal material coating process, coating, etc., to achieve the effect of excellent wear resistance, low cracking sensitivity and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

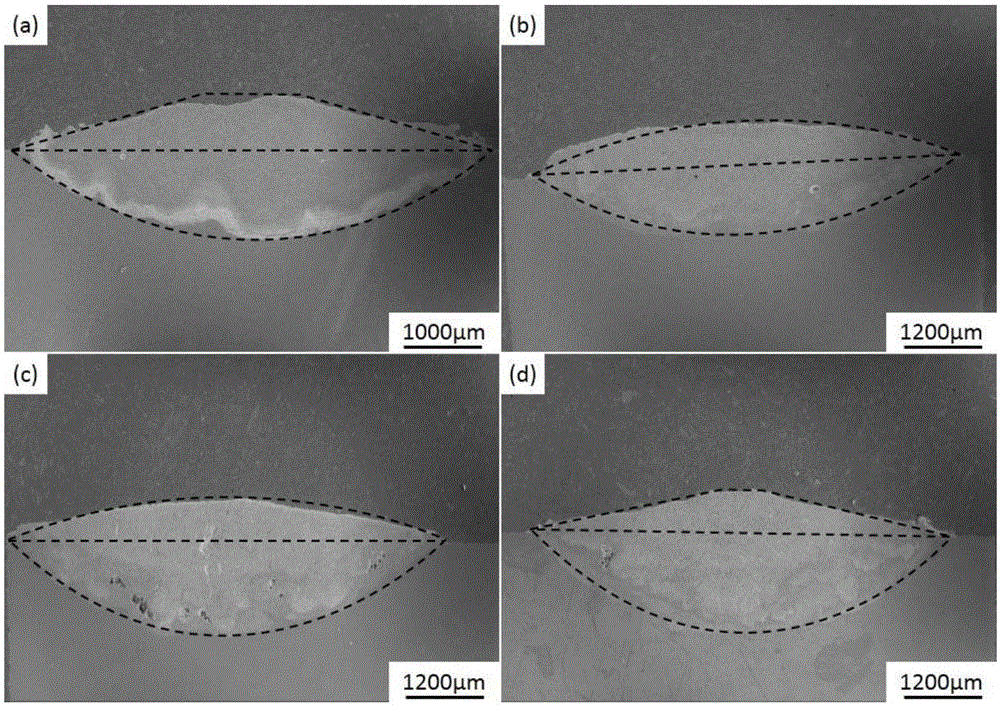

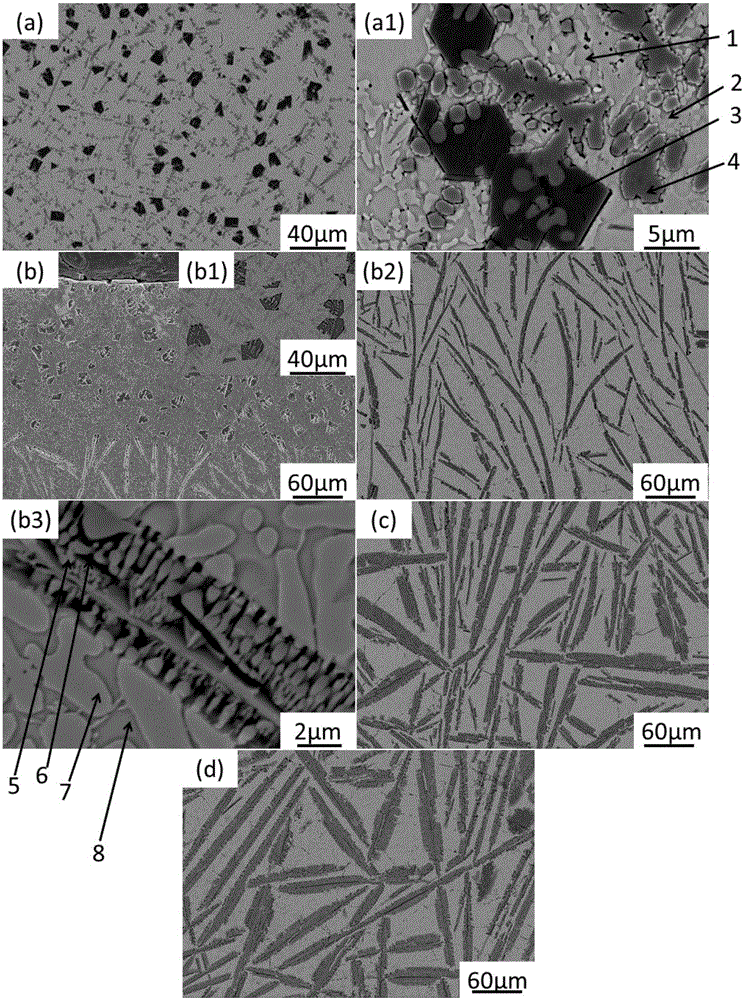

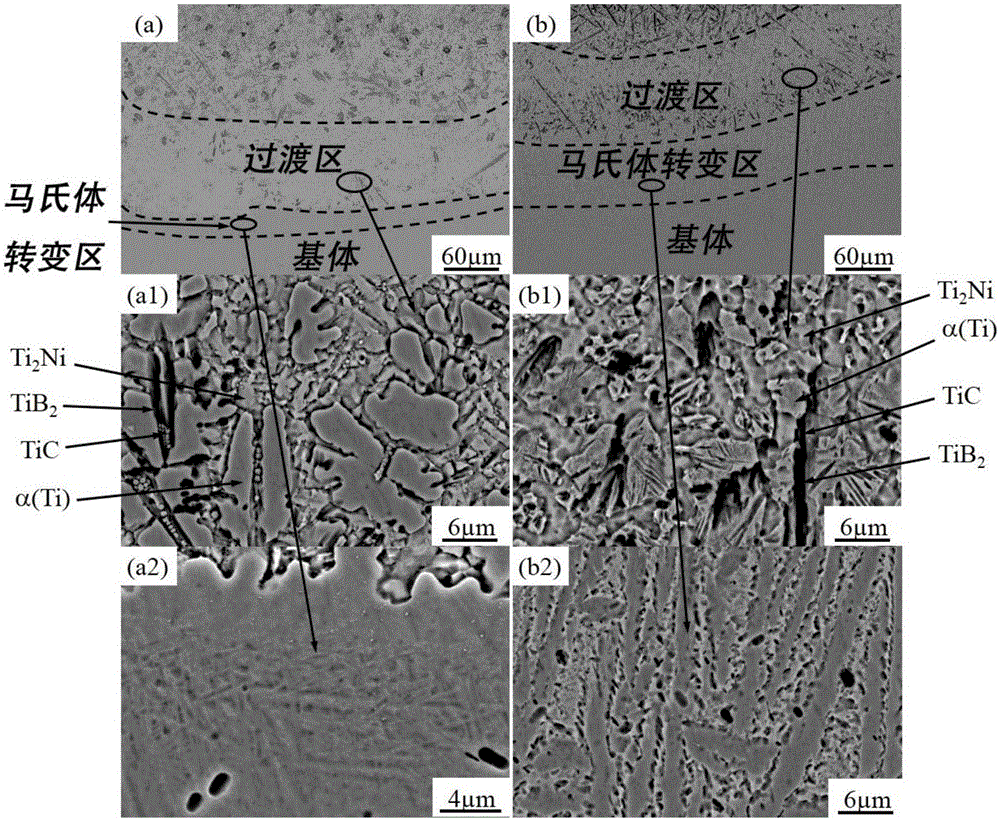

Image

Examples

Embodiment 1

[0044] a) Component design of cladding materials, design 4 different proportions of nickel-based alloy powder and carbide ceramic components as shown in Table 1:

[0045] Table 1 Different proportions of nickel-based alloy powder and carbide ceramic components

[0046] group design

NiCCrBSi(wt.%)

B 4 C (wt.%)

1

100

0

2

95

5

[0047] 3

85

15

4

75

25

[0048] b) The composite coating preparation process of component 1 comprises the following steps:

[0049] (1) Take the nickel-based alloy powder and the carbide ceramic powder in the above mass ratio, fully stir and grind the powder to form a uniform mixed powder;

[0050] (2) Using the improved pre-coating method on the titanium alloy Ti6Al4V substrate, a dense coating is pre-prepared on the titanium alloy substrate through a binder (polyvinyl alcohol), and the pre-coating is controlled The thickness is about 0.8mm;

[0051] (3) A li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com