Black rice anthocyanin-based cotton fabric anti-ultraviolet finishing agent

A black rice flower, anti-ultraviolet technology, applied in the direction of dyeing, fiber treatment, plant fiber, etc., can solve problems such as environmental pollution, and achieve the effects of comfortable hand feel, enhanced wrinkle resistance, and excellent anti-ultraviolet ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

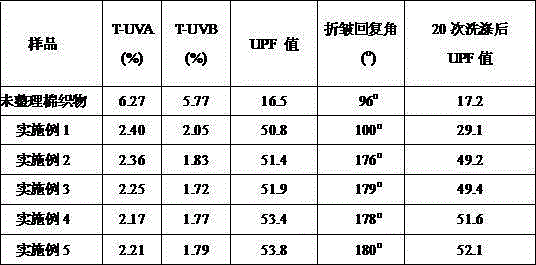

Embodiment 1

[0011] At room temperature, immerse 2g of cotton fabric in the anti-ultraviolet finishing agent for cotton fabric based on black rice anthocyanin, the bath ratio is 1:15, heat it up to 70°C and keep it warm for 60min, then lower the temperature to room temperature, take out the cotton fabric, and Dry at 70°C, then bake at 120°C for 5 minutes, and finally wash with water and dry to obtain finished cotton fabric. The composition of the black rice anthocyanin finishing agent for cotton fabric dyeing and anti-ultraviolet radiation is: black rice anthocyanin extract 30ml, citric acid 0g / L, sodium citrate 3g / L, sodium sulfate 1g / L and osmotic Agent JFC0.5g / L.

Embodiment 2

[0013] Using the same finishing process as in Example 1, 2g of cotton fabric is immersed in the cotton fabric anti-ultraviolet finishing agent based on black rice anthocyanin, the bath ratio is 1:15, wherein the cotton fabric dyeing and anti-ultraviolet radiation black The rice anthocyanin finishing agent is composed of: black rice anthocyanin extract 30ml, citric acid 5g / L, sodium citrate 3g / L, sodium sulfate 1g / L and penetrant JFC 0.5g / L.

Embodiment 3

[0015] At room temperature, immerse 2g of cotton fabric in the anti-ultraviolet finishing agent for cotton fabric based on black rice anthocyanin, the bath ratio is 1:20, heat it up to 80°C and keep it warm for 90min, when the temperature drops to room temperature, take out the cotton fabric and place it at 70°C Dry, then bake at 130°C for 3 minutes, and finally wash with water and dry to obtain finished cotton fabric. The black rice anthocyanin finishing agent for cotton fabric dyeing and anti-ultraviolet radiation described therein consists of: black rice anthocyanin extract 40ml, butane tetracarboxylic acid 3g / L, sodium citrate 3g / L, sodium sulfate 1g / L And penetrant JFC0.5g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com