Ultra-wideband artificial surface Plasmon low-pass filter

A technology of plasmonic polariton and low-pass filter, which is applied in the direction of waveguide devices, electrical components, circuits, etc., can solve the problem that the plasmonic waveguide structure cannot realize the high-efficiency conversion function of the microstrip line, and achieve good technical foresight and technical foresight Good, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

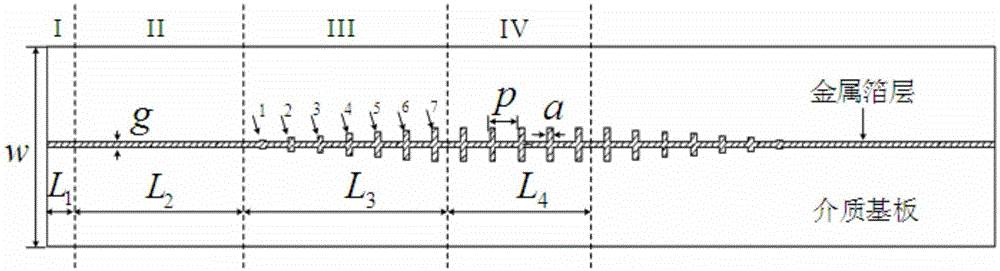

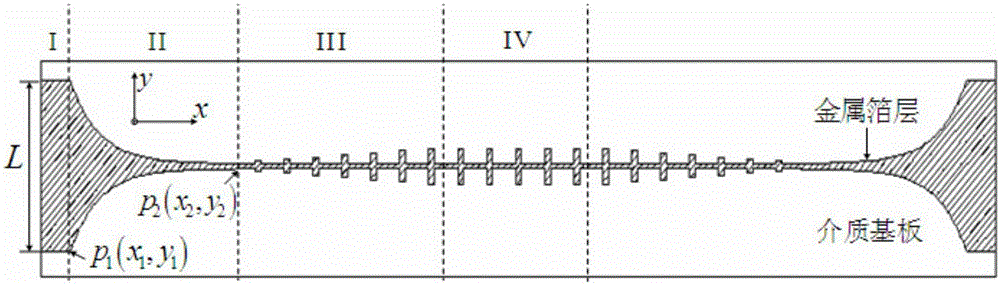

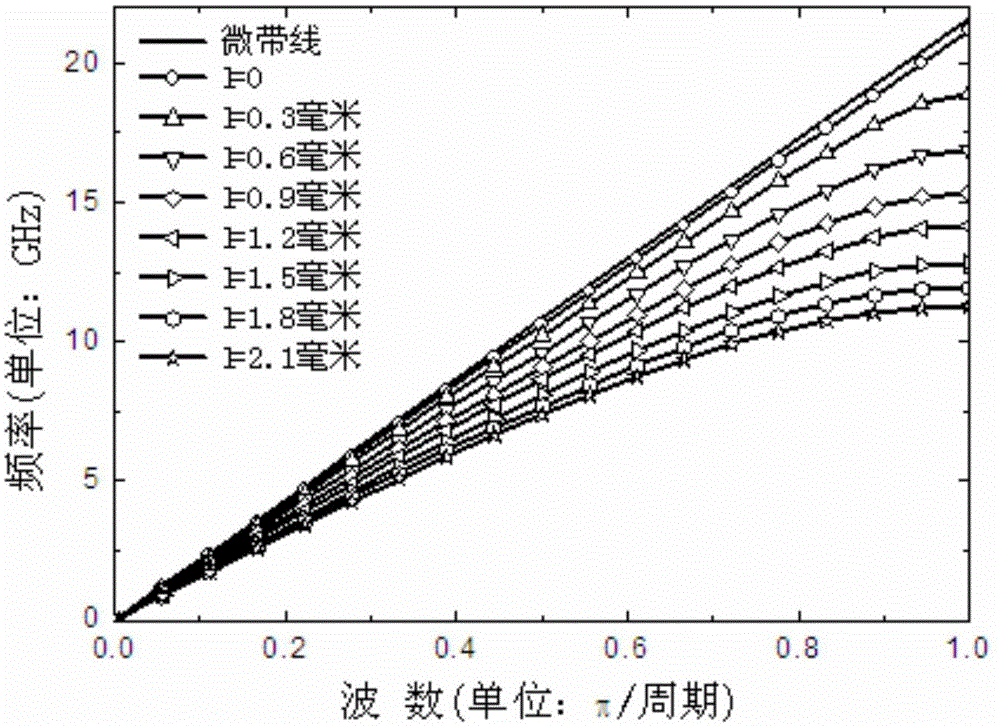

[0020] As shown in Fig. 1(a) and Fig. 1(b), the present invention includes a dielectric substrate layer and a metal foil layer printed on the upper and lower surfaces of the dielectric substrate. The waveguide structure is engraved on the metal foil layer, and the waveguide structure is mainly composed of the microstrip line part (area I) with both ends symmetrical, and the transition part (areas II and III) from the microstrip line structure with both ends symmetrical to the surface plasmon waveguide structure. And the intermediate surface plasmon waveguide part (region IV). Wherein, the microstrip line part includes a dielectric substrate layer, a metal central conduction strip and a metal grounding plate printed on the upper and lower surfaces of the substrate. The width of the metal ground plate is greater than the width of the metal central conductive strip. The transition part includes two transition stages. The first transition stage (region II) continues the metal cen...

Embodiment 2

[0022] Shown in Fig. 1 (a), Fig. 1 (b) is the front and back structural diagrams of the present invention, the horizontal total length of the present invention is 165 millimeters, and transverse width w=30 millimeters. The thickness of the metal foil layer is 0.018 mm, the thickness of the dielectric substrate is 0.254 mm, and the dielectric constant is 2.2. The total horizontal length of the part of area I is L 1 = 5 mm, wherein, the width of the metal center conduction band on the upper surface g = 0.75 mm, the lateral width of the ground plate on the lower surface L = 24 mm; the total horizontal length of the region II (the first transition stage on the left) is L 2 = 17.5 mm, where the metal center conduction band on the upper surface is consistent with the microstrip line, and the lateral width of the ground plate on the lower surface can be according to the Goubau curve Realize gradual change (note: the form of the curve is not unique, but it is necessary to ensure the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com