External cavity tuning laser

A laser and tone-tuning technology, which is applied in the field of cost-effective external cavity tuning lasers, can solve the problems of being unable to adapt to the application of lidar point cloud data, low overall system speed, and slow frame switching speed, achieving cost advantages, low production costs, The effect of improving tuning accuracy and resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

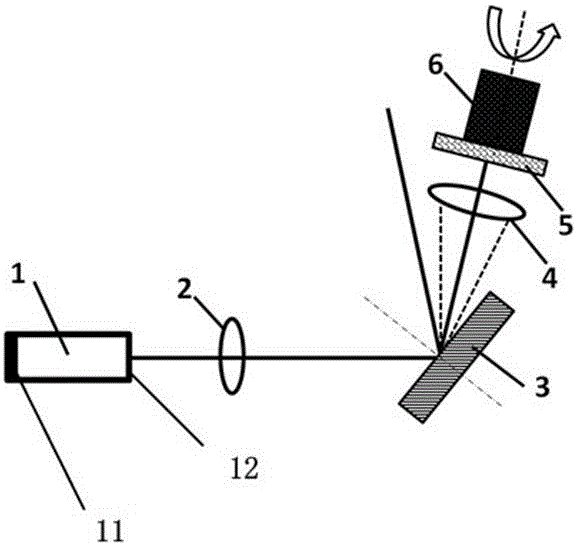

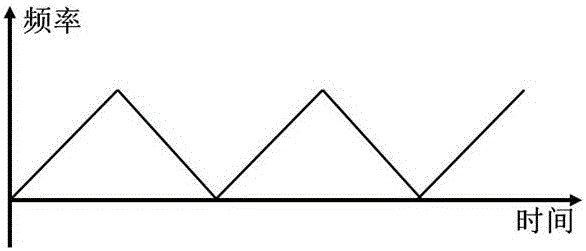

[0027] This embodiment provides an external cavity tuned laser, which can obtain a linear frequency-sweeping output through the pattern design of the metal-plated thin line area pattern on the mirror. This embodiment is suitable for optical frequency-modulated continuous wave laser radar as a frequency-sweeping laser light source.

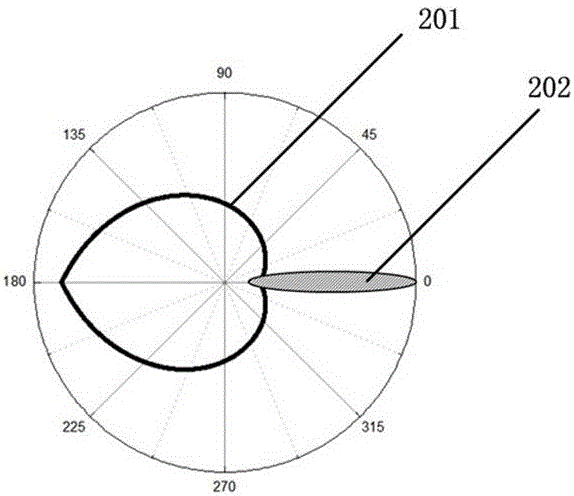

[0028] This example figure 1 As shown, the laser gain chip 1 has a center wavelength of 810 nm in the gain region, and its gain wavelength can be adjusted in the range of 780 nm to 840 nm. The laser gain chip 1 can be formed by a semiconductor Fabry Perot laser. The back end of the laser gain chip 1 has a high-reflection HR coating 11 for the 800nm infrared band, and the front end has an anti-reflection AR coating 12, so that as much laser light as possible can be emitted from the front end of the laser gain chip 1 and enters the collimating lens 2, wherein the laser output power used is 5mW. After the laser passes through the laser gain chip 1,...

Embodiment example 2

[0031] This embodiment provides a dual-wavelength external cavity tuned laser. Dual-wavelength lasers are often used in the fields of continuous wave difference frequency generation of terahertz waves, non-contact optical sensing, etc. There are many methods for manufacturing dual-wavelength lasers. achieve, such as Figure 4 As shown, the metal-plated fine-line area pattern set on the reflector is a pattern composed of two parallel gold-plated curves, which includes the metal-plated thin-line area pattern composed of metal-plated curve 401 and metal-plated curve 402. In this implementation The optical setting of the case is the same as that of the implementation case 1, and the laser gain chip adopts the same product. The pattern of mirror 5 is as Figure 4 As shown in , the two parallel curves represent the selected two wavelengths, and the wavelength spacing remains unchanged during the sweeping process, and the following is obtained: Figure 5 The wavelength-time curve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com