Ready-to-eat smoked sturgeon pieces and processing method thereof

A processing method and technology for sturgeon fillets, which are applied in the fields of food preparation, food science, and application, can solve the problems of not being able to impart external smoked flavor to fish, not listing safety testing indicators, and unsatisfactory effects of smoked products. The effect of economic added value, high product quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

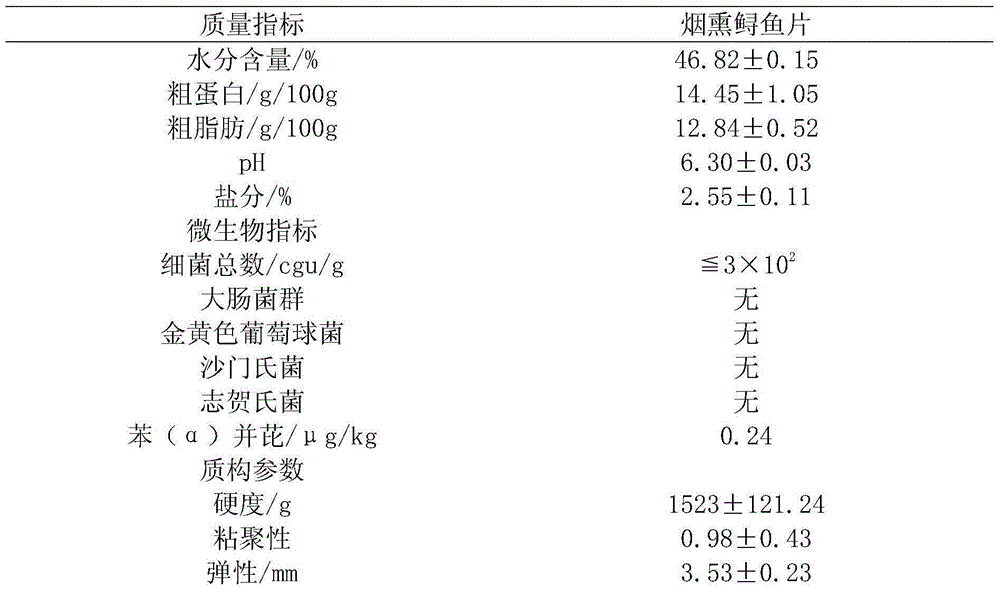

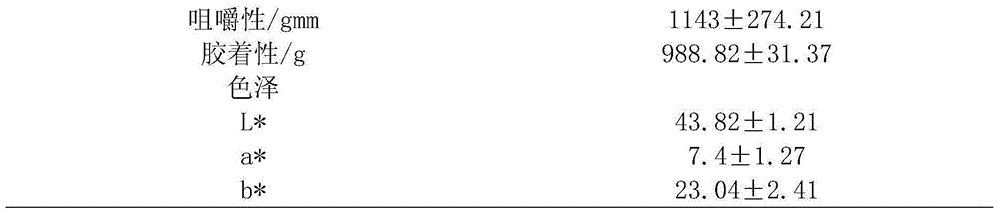

Examples

Embodiment 1

[0048] The present embodiment provides a kind of processing method of ready-to-eat smoked sturgeon fillets, comprising the following steps:

[0049] (1) Pretreatment: select fresh sturgeon, slaughter and remove the head and viscera, wash the surface mucus and intra-abdominal congestion with running water, and cut longitudinally into 1cm-thick sturgeon fillets;

[0050] (2) Pickling and seasoning: evenly apply the mixed seasoning to the sturgeon fillets (according to the fresh weight of the sturgeon fillets, the amount of the mixed seasoning is 100g / kg), and pickle and season at 4°C 3h, wherein, the mixed seasoning is prepared as follows: take 70 parts of pepper, 16 parts of Chinese pepper, 20 parts of Zanthoxylum bungeanum, 7 parts of grass fruit, 8 parts of nutmeg, and 9 parts of cinnamon, mix and grind them into powder; 10 parts of the powder, 5 parts of sugar, 4 parts of table salt, and 1.2 parts of chicken essence are mixed evenly (the "parts" here can be determined accord...

Embodiment 2

[0060] The present embodiment provides a kind of processing method of ready-to-eat smoked sturgeon fillets, comprising the following steps:

[0061] (1) Pretreatment: select fresh sturgeon, slaughter and remove the head and viscera, wash the mucus on the surface and congestion in the abdominal cavity with running water, and cut longitudinally into 0.8cm thick sturgeon fillets;

[0062] (2) Pickling and seasoning: apply the mixed seasoning evenly to the sturgeon fillets, and carry out pickling and seasoning at 2°C for 5 hours (based on the fresh weight of the sturgeon fillets, the consumption of the mixed seasoning is 80g / kg ), wherein, the mixed seasoning is prepared as follows: take 60 parts of pepper, 12 parts of Chinese pepper, 18 parts of Zanthoxylum bungeanum, 7 parts of grass fruit, 6 parts of nutmeg, 8 parts of cinnamon, mix and grind into powder; Mix 8 parts of the powder, 4 parts of sugar, 2 parts of salt, and 1 part of chicken bouillon;

[0063] (3) Cleaning: clean ...

Embodiment 3

[0068] The present embodiment provides a kind of processing method of ready-to-eat smoked sturgeon fillets, comprising the following steps:

[0069] (1) Pretreatment: select fresh sturgeon, slaughter and remove the head and viscera, wash the surface mucus and intra-abdominal congestion with running water, and cut longitudinally into 1.2cm thick sturgeon fillets;

[0070] (2) Pickling and seasoning: Apply the mixed seasoning evenly to the sturgeon fillets, and pickle and season at 8°C for 1 hour (based on the fresh weight of the sturgeon fillets, the amount of the mixed seasoning is 120g / kg ), wherein, the mixed seasoning is prepared as follows: take 80 parts of pepper, 18 parts of Chinese pepper, 24 parts of Zanthoxylum bungeanum, 9 parts of grass fruit, 10 parts of nutmeg, 12 parts of cinnamon, mix and grind into powder; 12 parts of the powder, 6 parts of sugar, 6 parts of salt, and 1.6 parts of chicken essence are mixed well;

[0071] (3) Cleaning: clean the mixed seasoning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com