Super-hydrophobic hollow Fe3O4/mesoporous silicon dioxide nanocomposite, preparation method and application thereof

A technology of mesoporous silica and nanocomposite materials, applied in chemical instruments and methods, alkali metal compounds, adsorbed water/sewage treatment, etc., can solve the problems of hindering large-scale application of materials, poor circulation effect, increased energy consumption, etc. problems, to achieve the effect of improving oil absorption effect, saving reagents, and improving oil absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

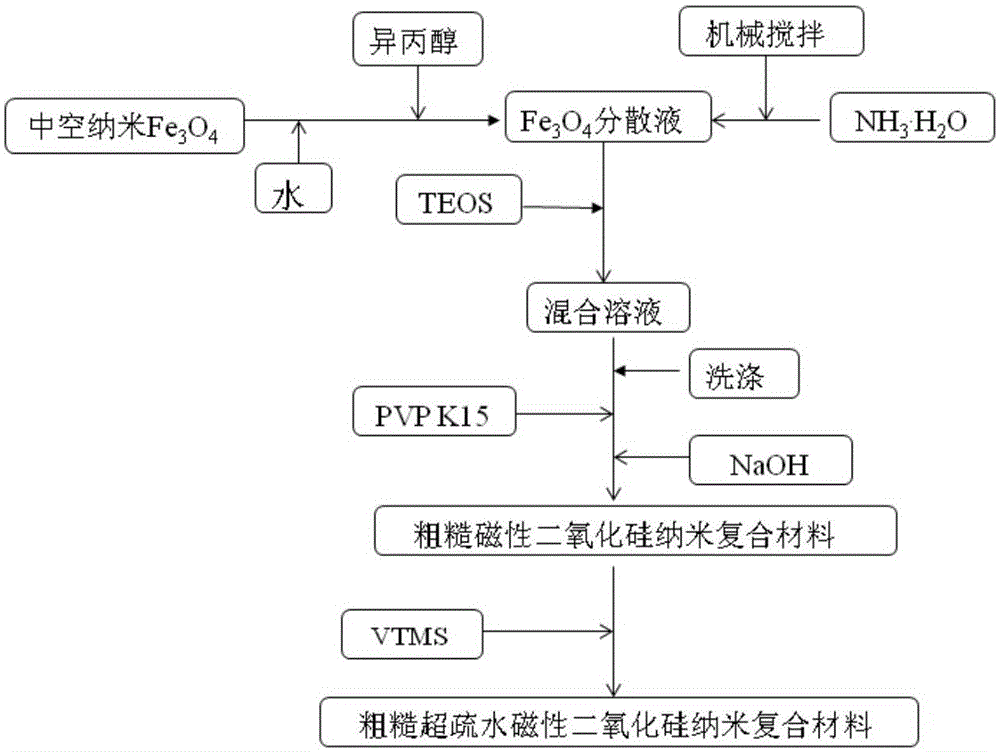

[0028] A kind of superhydrophobic hollow Fe of the present invention 3 o 4 / The preparation method of mesoporous silica nanocomposite material, specific preparation process such as figure 1 , including the following steps:

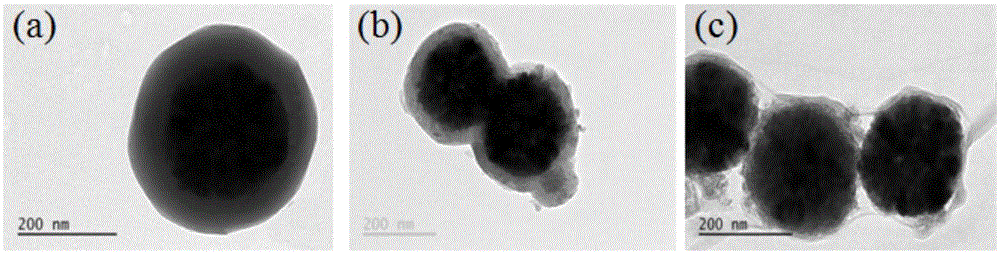

[0029] The first step: the hollow Fe 3 o 4 Nanospheres were dissolved in isopropanol solution to form Fe with a mass concentration of 3.3 mg / mL 3 o 4 solution, ultrasonically disperse at 25-35°C for 10-20min to obtain Fe 3 o 4 Precursor solution is transferred to a three-necked flask, wherein the hollow Fe 3 o 4 The particle size of the nano-microspheres is 220-260nm, and the isopropanol solution is composed of deionized water and isopropanol in a volume ratio of 1:(2-4);

[0030] In the second step, take 30-50mLFe 3 o 4 Precursor solution, add 2.6~3mLNH 3 .H 2 O, stir at room temperature for 10-20min, then slowly add 0.9-1.1mLTEOS in batches and continue to stir for reaction, the reaction time is 5-7h;

[0031] The third step is to wash the ...

Embodiment 1

[0034] In the first step, the hollow Fe 3 o 4 Nanospheres were dissolved in isopropanol solution to form Fe with a mass concentration of 3.3 mg / mL 3 o 4 solution, sonicated at 25°C for 10 min to form Fe 3 o 4 Precursor solution is transferred to a three-necked flask, in which the hollow Fe 3 o 4 The particle size of the nanospheres is 220nm, and the isopropanol solution is composed of 10mL water and 20mL isopropanol;

[0035] The second step, to 30mL, the Fe obtained in the first step 3 o 4 Add 2.6mL NH to the precursor solution 3 .H 2 O, stirred at room temperature for 10 min, then slowly added 0.9mLTEOS in portions at room temperature and continued to stir the reaction, the reaction time was 5h;

[0036] In the third step, the product obtained in the second step was washed with absolute ethanol and deionized water several times, redispersed in 80mL of deionized water, then added 0.8g of PVPK15, stirred at 90°C, and the reaction time was 2.5h , adding 0.6g NaOH to ...

Embodiment 2

[0039] In the first step, the hollow Fe 3 o 4 Nanospheres were dissolved in isopropanol solution to form Fe with a mass concentration of 3.3 mg / mL 3 o 4 solution, sonicated at 30°C for 15 min to form Fe 3 o 4 Precursor solution is transferred to a three-necked flask, in which the hollow Fe 3 o 4 The particle size of the nanospheres is 240nm, and the isopropanol solution is composed of 10mL water and 30mL isopropanol;

[0040] The second step, to 40mL, the Fe obtained in the first step 3 o 4 Add 2.8mL NH to the precursor solution 3 .H 2 O, stirred at normal temperature for 15min, then slowly added 1.0mLTEOS in portions at normal temperature and continued to stir the reaction, the reaction time was 6h;

[0041] In the third step, the product obtained in the second step was washed with absolute ethanol and deionized water several times, redispersed in 80mL of deionized water, and then 0.9g of PVPK15 was added, and the temperature of the water bath was raised to 95°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com