Method for preparing superhydrophobic and self-cleaning glass

A self-cleaning, super-hydrophobic technology, applied in the field of glass manufacturing, can solve the problems of easy shedding of the coating and weak bonding force between the hydrophobic coating and the glass substrate, and achieve the effects of not easy to fall off, good super-hydrophobicity, and excellent light transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

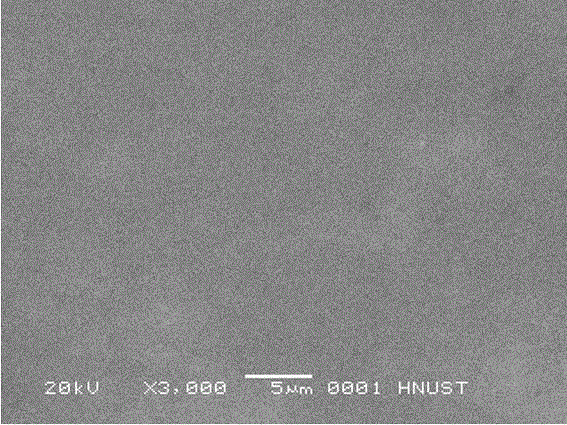

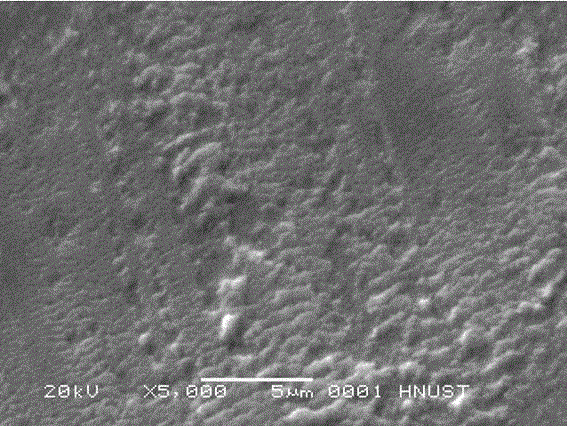

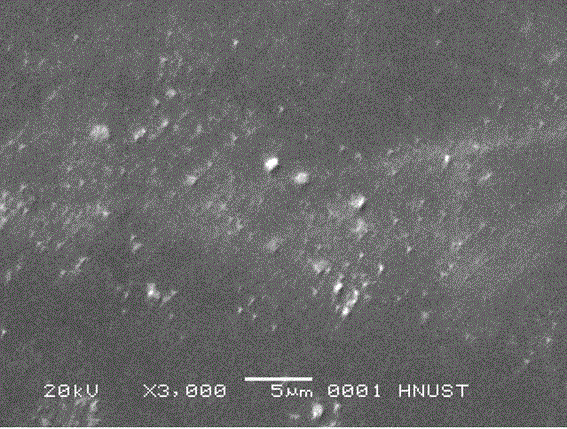

Image

Examples

Embodiment 1

[0040] A preparation method of superhydrophobic self-cleaning glass, comprising the following steps:

[0041] (1) Hydroxylation of ordinary glass surface: firstly cut the ordinary glass piece into 10*10mm, ultrasonic cleaning; then prepare piranha solution, control the temperature at 80°C, add clean ordinary glass, control the oxidation time at 60min, and use it after stopping Rinse with deionized water and dry;

[0042] (2) Double bond on the surface of the glass: Put 10 pieces of hydroxylated glass on the surface in 100mL of toluene, add 5mL of γ-methacryloxypropyltrimethoxysilane, stop the reaction after reflux for 24h, take out Glass slides were ultrasonically cleaned with ethanol and water, and dried at room temperature;

[0043] (3) Glass-grafted polystyrene: In the reaction bottle, add 10 double-bonded glass sheets prepared in step 2, the reaction medium is distilled water, and the polymerization temperature is 70°C; add 10 mL of styrene monomer, Under the protection ...

Embodiment 2

[0045] A preparation method of superhydrophobic self-cleaning glass, comprising the following steps:

[0046] (1) Hydroxylation of ordinary glass surface: firstly cut the ordinary glass sheet into 10*10mm, ultrasonic cleaning; then configure piranha solution, control the temperature at 500C, add clean ordinary glass, control the oxidation time at 120min, and use deionization after stopping Wash with water and dry;

[0047](2) Double bond on the surface of the glass: put 10 pieces of hydroxylated glass on the surface in 100mL of toluene, add 10mL of γ-methacryloxypropyltrimethoxysilane, stop the reaction after reflux for 5h, take out Glass slides were ultrasonically cleaned with ethanol and water, and dried at room temperature;

[0048] (3) Glass-grafted polystyrene: In the reaction bottle, add 10 double-bonded glass sheets prepared in step 2, the reaction medium is distilled water, and the polymerization temperature is 60°C; add 10 mL of styrene monomer, Under the protection...

Embodiment 3

[0050] A preparation method of superhydrophobic self-cleaning glass, comprising the following steps:

[0051] (1) Hydroxylation of ordinary glass surface: firstly cut the ordinary glass sheet into 10*10mm, ultrasonic cleaning; then configure piranha solution, control the temperature at 1000C, add clean ordinary glass, control the oxidation time at 1min, stop with deionization Wash with water and dry;

[0052] (2) Double bond on the surface of the glass: Put 10 pieces of hydroxylated glass on the surface in 100mL of toluene, add 1mL of γ-methacryloxypropyltrimethoxysilane, stop the reaction after reflux for 30h, take out Glass slides were ultrasonically cleaned with ethanol and water, and dried at room temperature;

[0053] (3) Glass-grafted polystyrene: In the reaction bottle, add 10 double-bonded glass sheets prepared in step 2, the reaction medium is distilled water, and the polymerization temperature is 80°C; add 10 mL of styrene monomer, Under the protection of N2, 0.09 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com