Coenzyme regeneration system and establishment method thereof

A technology of coenzyme regeneration and enzyme solution, applied in the field of coenzyme regeneration system and preparation thereof, can solve problems such as poor stability, high cost, and difficulty in reusing, and achieve the effects of cost reduction, high coenzyme regeneration efficiency, and simple and convenient preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

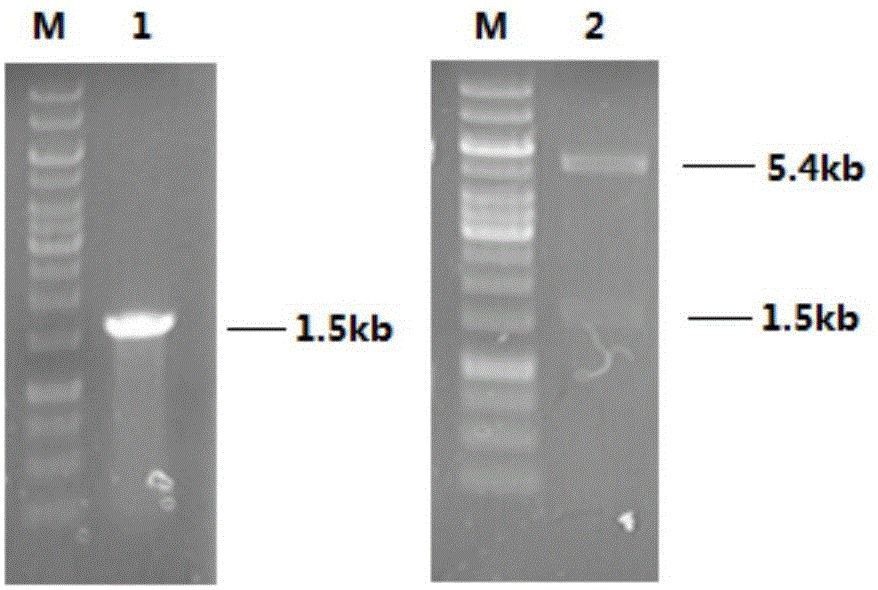

[0055] Example 1: PCR amplification of target gene

[0056] (1) PCR amplification primers

[0057] The primers were designed according to the formate dehydrogenase (FDH) threonine deaminase (TD) gene sequence (Genbanknumber: XM_001525495 and AAB18593) and its pre- and post-sequence. After screening and verification, the best formate dehydrogenase (FDH) upstream primer is 5’-AAA CATATG AAAATCGTTCTCGTTTTGTACTCC-3' (underlined is the NdeI restriction site); the downstream primer is 5'-AAA CTCGAG TGCGACCTTTTTGTCATTAC-3' (underlined is the XhoI restriction site). Design the upstream and downstream primers according to the gene sequence of threonine deaminase (AAB18593). After screening and verification, the best upstream primer is 5’-AAA AAGCTT GTTAGCAGCCGGATCTCAG-3' (the underlined is the HindIII restriction site); the downstream primer is 5'-AAA CATATG GTATTAAAACAAATTCTTC-3' (underlined is the NdeI restriction site).

[0058] Using the total DNA of Candida and E. coli as templates...

Embodiment 2

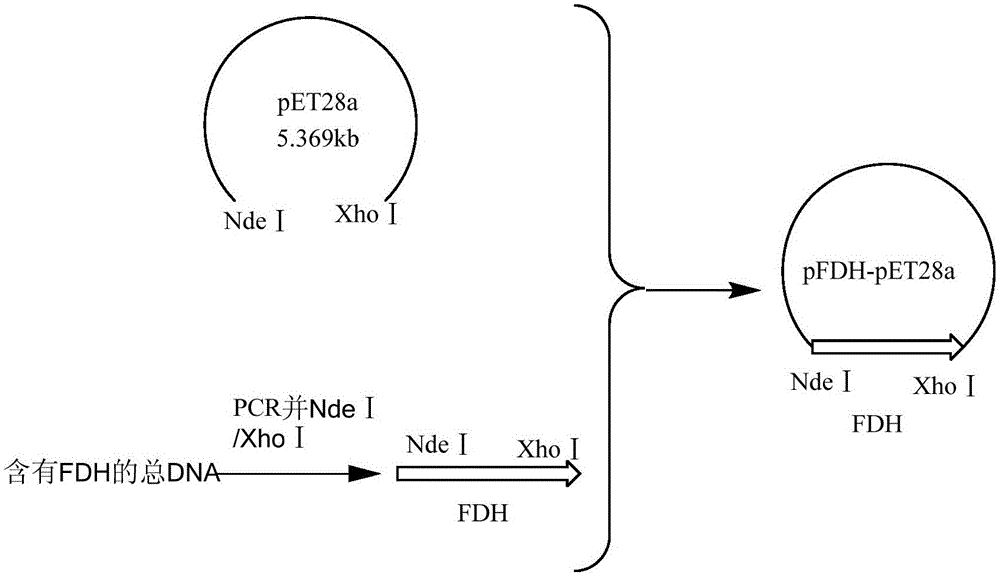

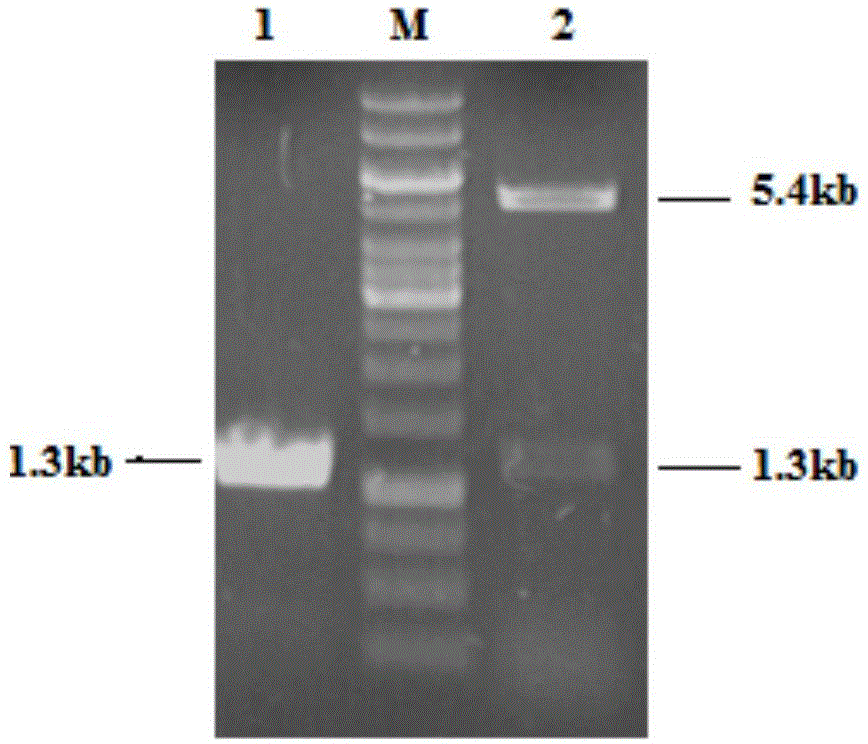

[0068] Example 2: Construction of recombinant plasmid

[0069] The plasmid construction process is as follows figure 1 As shown (take the construction of FDH as an example), using the total Candida DNA as a template, the amplified gene fragments or the gene fragments connected to the T vector are double digested with specific endonucleases NdeI and XhoI, and double digested at the same time The vector plasmid was purified and recovered, and then ligated at 16°C for 5 hours. The ligated product was transformed into competent cells E.coliDH5α. The single colony transformed on the LB solid plate was picked and received in 5mL LB liquid medium (according to the plasmid Add corresponding antibiotics for resistance), culture overnight at 37°C with shaking in a shaker at 220r / min. The plasmid was extracted, and the plasmid was picked for double enzyme digestion verification. After verification, the constructed plasmid pFDH-pET28a was subjected to DNA sequence determination.

[0070] (1) ...

Embodiment 3

[0076] Example 3: Construction of co-expression recombinant strains

[0077] Co-transform pFDH-pET28a and pLDH-pET21a into E.coli BL21 (DE3), and spread on LB (Amp and Kan each 100μg / ml) solid plate, on LB (Amp and Kan each 100μg / ml) solid plate The single colony that grows is the strain containing both formate dehydrogenase and leucine dehydrogenase genes, and the genetically engineered strain will be named E.coliBL21-FDH / LDH. The strain can simultaneously express formate dehydrogenase and leucine dehydrogenase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com