Technology for recovering silver from zinc hydrometallurgy leaching residue

A technology of hydrometallurgy and leaching slag, which is applied in the field of silver recovery, can solve the problems of large consumption of reagents, high energy consumption, and serious pollution, and achieve the effects of being conducive to widespread promotion, simple process, and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

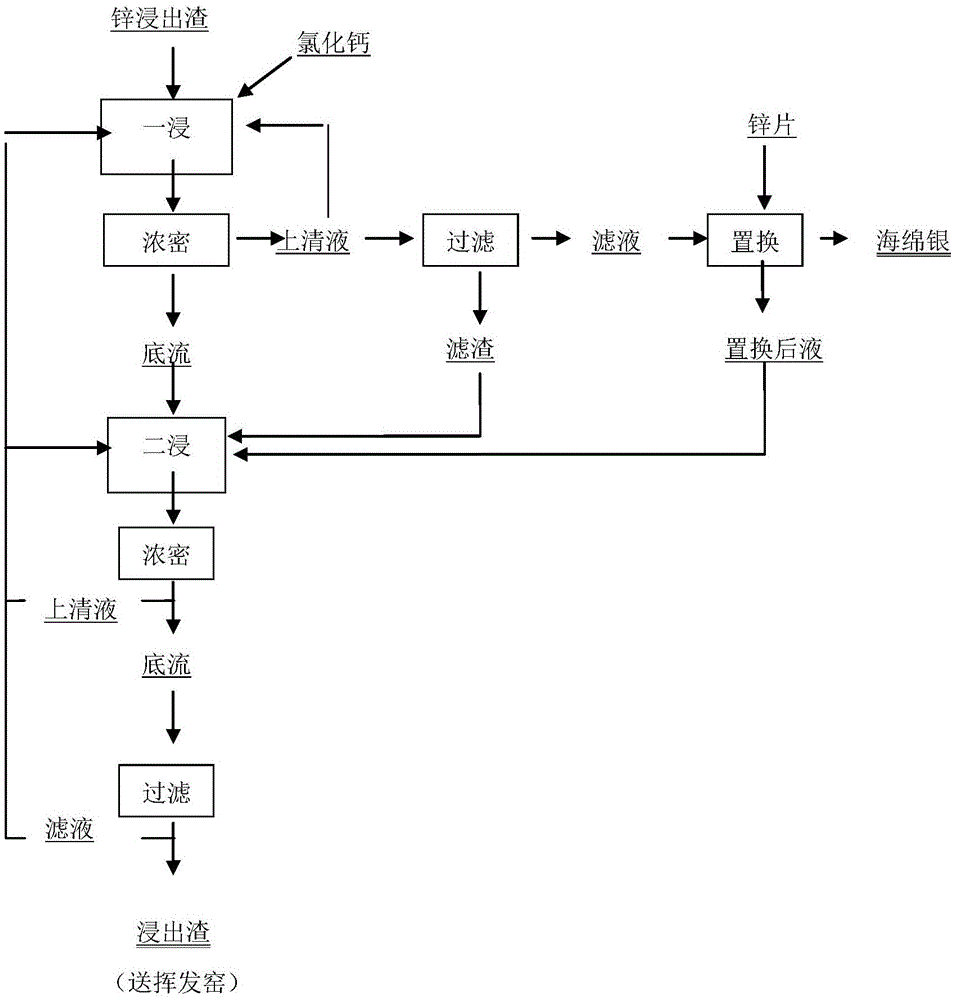

Method used

Image

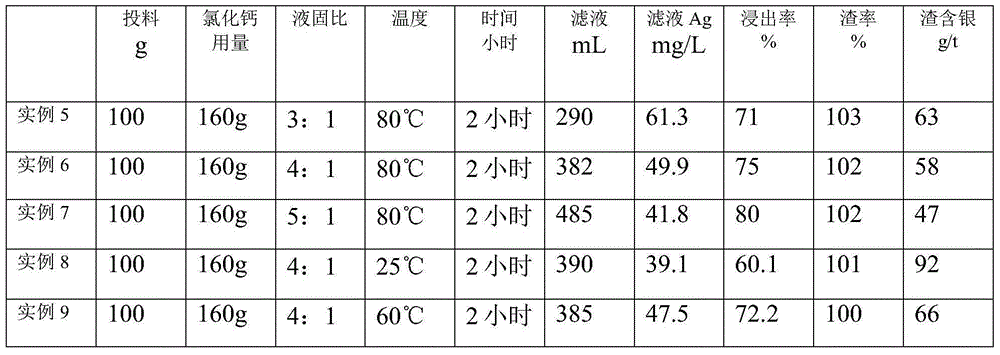

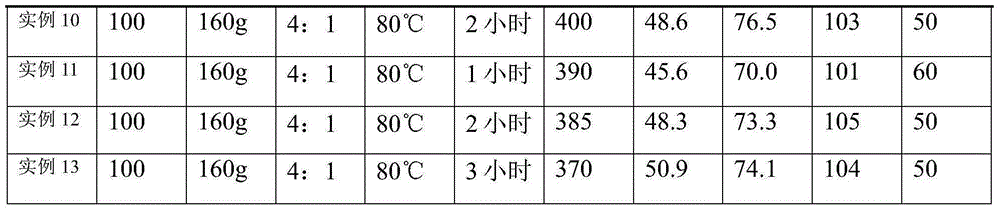

Examples

Embodiment 1

[0036] 100g zinc leaching slag (containing 254g / t silver), add 120g calcium chloride (300g / l), according to the liquid-solid ratio of 4:1, at 80 ° C, leaching for 2 hours at a time, liquid-solid separation, to obtain a leaching slag and The filtrate was 385ml, containing 41.4mg / l of silver. The filtrate was replaced with metallic zinc to obtain 3.1g of replaced sponge silver, containing 5032.3g / t of silver. After the replacement, the liquid was used to leaching the primary leaching residue for secondary leaching and leaching at 60°C for 60 minutes. , liquid-solid separation, 101g of secondary leaching residue was obtained, containing 39.7g / t of silver, and 385ml of filtrate was obtained, containing 6.4mg / l of silver;

[0037] The primary leaching rate is 62.7%, the secondary leaching rate is 9.7%, and the total leaching rate is 72.4%.

Embodiment 2

[0039] 100g zinc leaching slag (containing 254g / t silver), add 160g calcium chloride (400g / l), according to the liquid-solid ratio of 4:1, at 80 ℃, leaching for 2 hours at a time, liquid-solid separation, to obtain a leaching slag and The filtrate was 385ml, containing 48.8mg / l of silver, and the filtrate was replaced with metallic zinc to obtain 3.15g of replacement sponge silver, containing 5882.1g / t of silver. After the replacement, the liquid was used for leaching the primary leaching residue for secondary leaching, and leaching at 60°C for 60 minutes , liquid-solid separation, 102g of secondary leaching residue was obtained, containing 36.5g / t of silver, and 380ml of filtrate was obtained, containing 8.02mg / l of silver;

[0040] The primary leaching rate is 74%, the secondary leaching rate is 12%, and the total leaching rate is 86%.

Embodiment 3

[0042] 100g zinc leaching residue (containing 254g / t silver), add 200g calcium chloride (500g / l), according to the liquid-solid ratio of 4:1, at 80 ℃, leaching for 2 hours at a time, liquid-solid separation, to obtain a leaching residue and The filtrate was 370ml, containing 50.8mg / l of silver. The filtrate was replaced with metallic zinc to obtain 3.3g of replaced sponge silver, containing 5844.5g / t of silver. After the replacement, the liquid was used for leaching the primary leaching residue for secondary leaching and leaching at 60°C for 60 minutes. , liquid-solid separation, 103g of secondary leaching residue was obtained, containing 31.5g / t of silver, and 380ml of filtrate was obtained, containing 8.59mg / l of silver;

[0043] The primary leaching rate is 75%, the secondary leaching rate is 12.8%, and the total leaching rate is 87.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com