Preparing method for Sm-Co/Fe-Co series biphase coupling magnetic nanowire array

A nanowire array and magnetic nanotechnology, which is applied in the field of preparation of Sm-Co/Fe-Co system dual-phase coupled magnetic nanowire arrays, can solve the problem of poor contact between the cathode and the template gold film, extremely high flatness requirements, and high conditions. higher problems, to achieve the effect of dense structure, easy deposition, simple process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

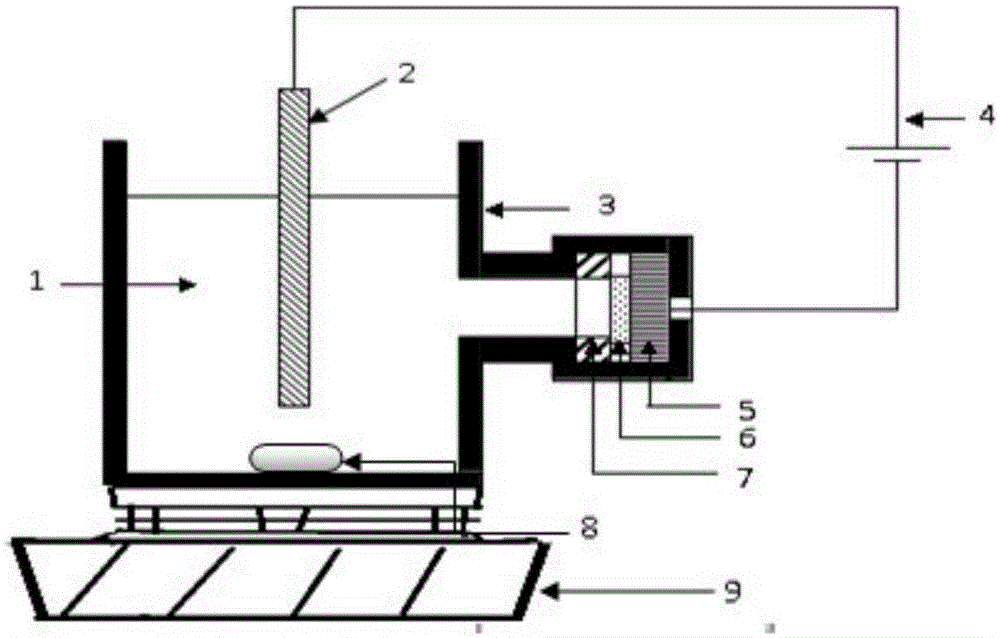

[0041] The first step is to install a dedicated single-tank double-liquid alternate deposition device:

[0042] Such as figure 1 Examples shown;

[0043] The second step, the processing work before AAO template deposition:

[0044] First, soak the AAO template with gold spraying on the bottom in deionized water, place it in a water bath at 60°C for 1 min, and then place it in an ultrasonic wave until the residual bubbles in the nanopores are driven away;

[0045] The third step, configuration of Sm-Co phase deposition solution:

[0046] Dissolve SmCl in deionized water 3 ·6H 2 O, CoCl 2 ·6H 2 O, H 3 BO 3 , glycine and ascorbic acid, the resulting solution of SmCl 3 ·6H 2 The concentration of O is 0.4mol / L, CoCl 2 ·6H 2 O concentration is 0.1mol / L, H 3 BO 3 The concentration of Glycine is 30g / L, the concentration of glycine is 0.2mol / L, and the concentration of ascorbic acid is 3g / L;

[0047] The fourth step, configuration of Fe-Co phase deposition solution:

[...

Embodiment 2

[0061] The first step is to install a dedicated single-tank double-liquid alternate deposition device:

[0062] Such as figure 1 Examples shown;

[0063] The second step, the processing work before AAO template deposition:

[0064] First, soak the AAO template with gold spraying on the bottom in deionized water, place it in a water bath at 60°C for 1 min, and then place it in an ultrasonic wave until the residual bubbles in the nanopores are driven away;

[0065] The third step, configuration of Sm-Co phase deposition solution:

[0066] Dissolve SmCl in deionized water 3 ·6H 2 O, CoCl 2 ·6H 2 O, H 3 BO, glycine and ascorbic acid, SmCl in the resulting solution 3 ·6H 2 The concentration of O is 0.3mol / L, CoCl 2 ·6H 2 O concentration is 0.05mol / L, H 3 The concentration of BO is 25g / L, the concentration of glycine is 0.1mol / L, and the concentration of ascorbic acid is 2g / L;

[0067] The fourth step, configuration of Fe-Co phase deposition solution:

[0068] Dissolve...

Embodiment 3

[0074] The first step is to install a dedicated single-tank double-liquid alternate deposition device:

[0075] Such as figure 1 Examples shown;

[0076] The second step, the processing work before AAO template deposition:

[0077] First, soak the AAO template with gold spraying on the bottom in deionized water, place it in a water bath at 60°C for 1 min, and then place it in an ultrasonic wave until the residual bubbles in the nanopores are driven away;

[0078] The third step, configuration of Sm-Co phase deposition solution:

[0079] Dissolve SmCl in deionized water 3 ·6H 2 O, CoCl 2 ·6H 2 O, H 3 BO 3 , glycine and ascorbic acid, the resulting solution of SmCl 3 ·6H 2 The concentration of O is 0.5mol / L, CoCl 2 ·6H 2 O concentration is 0.15mol / L, H 3 The concentration of BO is 35g / L, the concentration of glycine is 0.3mol / L, and the concentration of ascorbic acid is 4g / L;

[0080] The fourth step, configuration of Fe-Co phase deposition solution:

[0081] Diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com