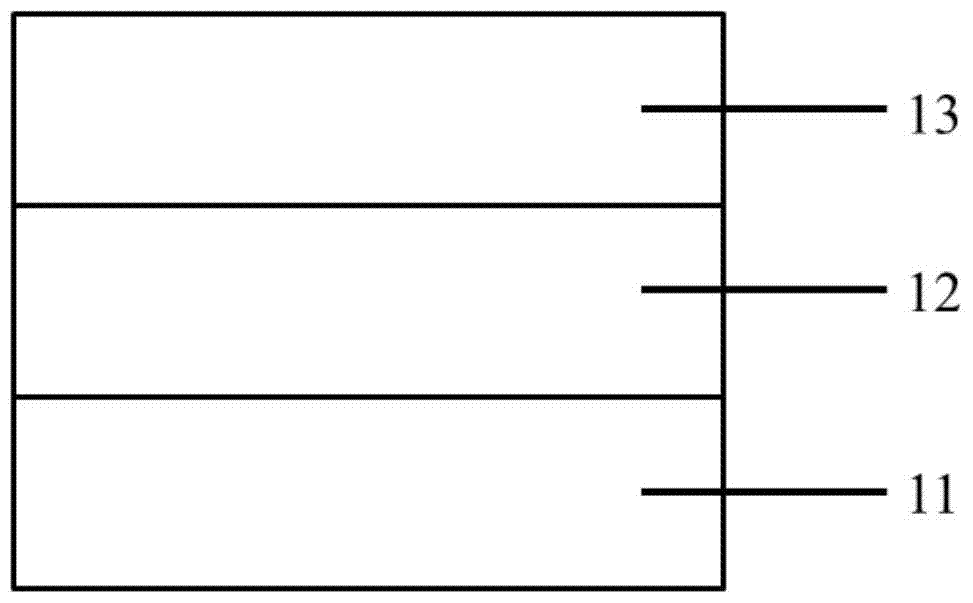

Gaas thin film grown on Si substrate and preparation method thereof

A substrate and thin film technology, applied in the field of GaAs thin films and their preparation, can solve the problems of deteriorating device performance, GaAs misfit dislocation, affecting the surface flatness of GaAs semiconductor devices, etc. GaAs epitaxy thin high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

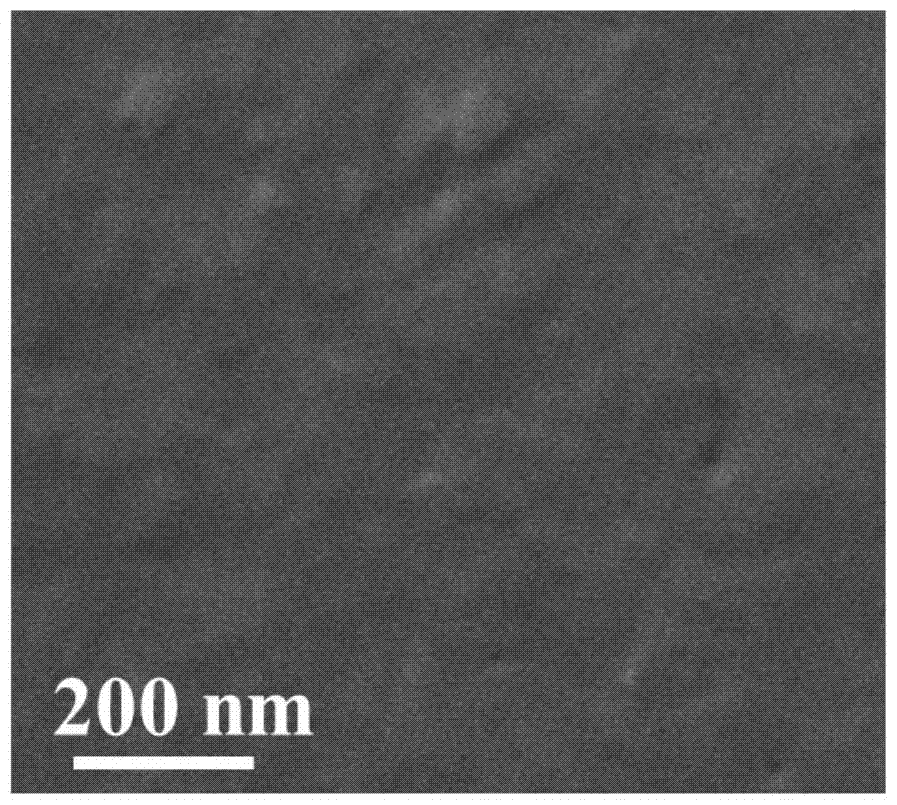

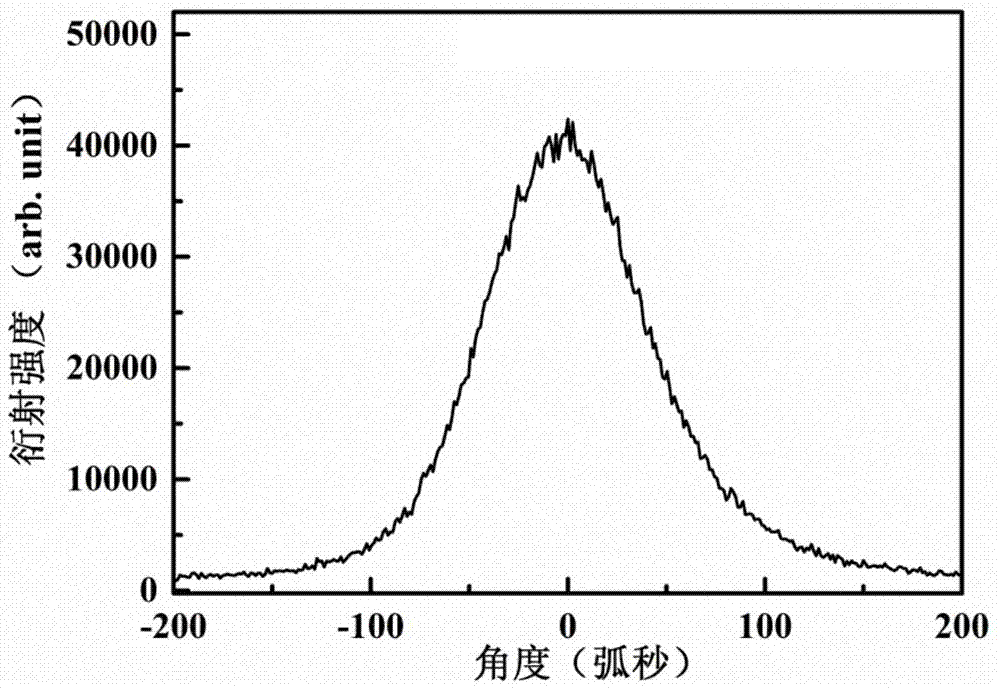

Embodiment 1

[0037] The preparation method of the GaAs thin film grown on the Si substrate of the present embodiment comprises the following steps:

[0038] (1) Si substrate cleaning: After washing with acetone and deionized water, organic matter on the surface of the substrate is removed; the Si substrate is placed in HF:H 2 Ultrasound in O=1:10 solution for 1 minute, then rinse with deionized water to remove surface oxides and organic matter; dry the cleaned Si substrate with high-purity nitrogen;

[0039] (2) Si substrate pretreatment: After the Si substrate is cleaned, send it to the molecular beam epitaxy sampling chamber for pre-degassing for 15 minutes; then send it to the transfer chamber for degassing at 300°C for 0.5 hours, and then send it to the growth chamber after degassing;

[0040] (3) Si substrate deoxidation film: after the Si substrate enters the growth chamber, the substrate temperature is raised to 950 ° C, and the high temperature is baked for 15 minutes to remove the...

Embodiment 2

[0048] The preparation method of the GaAs thin film grown on the Si substrate of the present embodiment comprises the following steps:

[0049] (1) Si substrate cleaning: After washing with acetone and deionized water, organic matter on the surface of the substrate is removed; the Si substrate is placed in HF:H 2 Ultrasonic in O=1:10 solution for 10 minutes, then rinsed with deionized water to remove surface oxides and organic matter; the cleaned Si substrate was dried with high-purity nitrogen;

[0050] (2) Si substrate pretreatment: After the Si substrate is cleaned, it is sent to the molecular beam epitaxy sampling chamber for pre-degassing for 30 minutes; then sent to the transfer chamber for degassing at 400 °C for 2 hours, and then sent to the growth chamber after degassing;

[0051] (3) Si substrate deoxidation film: after the Si substrate enters the growth chamber, the temperature of the substrate is raised to 1050 ° C, and the high temperature is baked for 30 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com