Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the field of microelectronics, can solve the problems of inability to dissipate heat and low withstand voltage, and achieve the effect of improving the withstand voltage and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

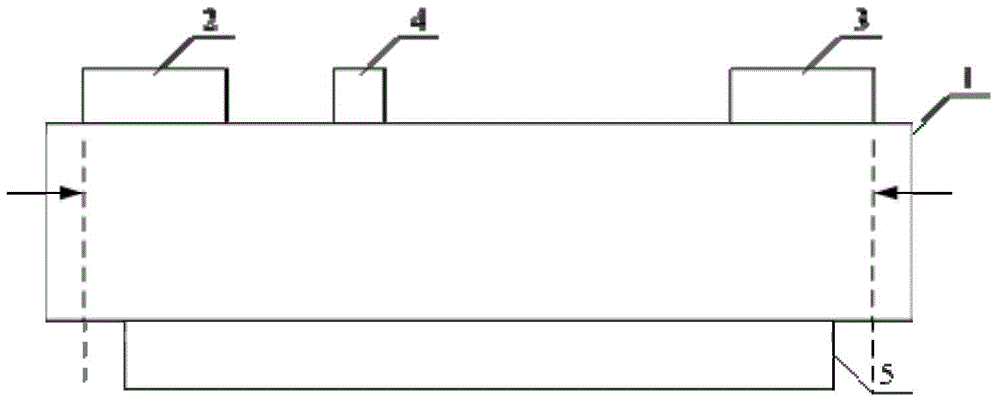

[0063] figure 1 is a cross-sectional view of the semiconductor device provided by Embodiment 1 of the present invention. like figure 1 As shown, the semiconductor device includes:

[0064] Semiconductor layer 1.

[0065] A source 2 and a drain 3 located on the semiconductor layer 1 , and a gate 4 located on the semiconductor layer 1 and between the source 2 and the drain 3 .

[0066] A thermally conductive and / or voltage resistant layer 5 is disposed below the semiconductor layer 1 .

[0067] Preferably, the semiconductor layer may include a buffer layer and a channel layer stacked sequentially from bottom to top.

[0068] Preferably, the channel layer may be a silicon carbide-based material, and the semiconductor device may be a silicon carbide device.

[0069] Preferably, the channel layer further includes a barrier layer, the barrier layer and the channel layer form a heterojunction structure, and a two-dimensional electron gas is formed at the interface of the heteroj...

Embodiment 2

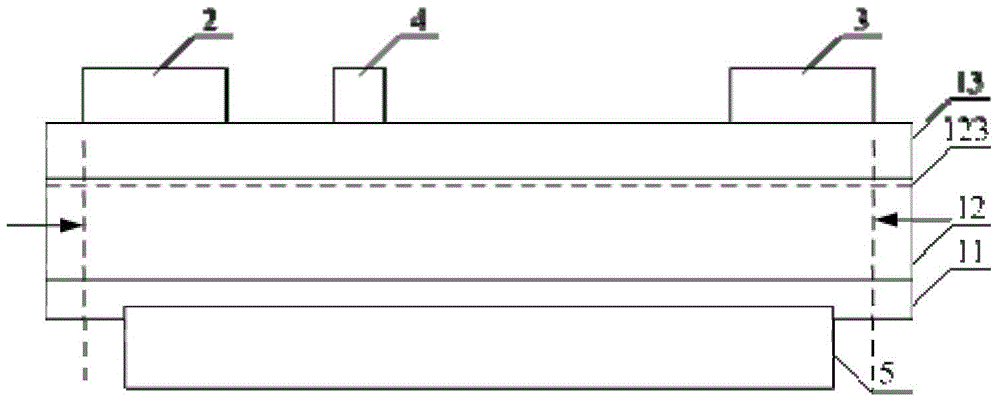

[0078] figure 2 It is a cross-sectional view of a gallium nitride semiconductor device provided in Embodiment 2 of the present invention. like figure 2 As shown, different from the semiconductor device provided in Embodiment 1 of the present invention, the semiconductor layer of the semiconductor device provided in Embodiment 2 includes from bottom to top: buffer layer 11, nitride channel layer 12 and nitride barrier layer 13. Among them, 123 is a two-dimensional electron gas. The thermally conductive and / or pressure-resistant layer 5 is disposed within the buffer layer 11 .

[0079] Wherein, the material of the buffer layer 11 can be group III nitrides such as aluminum gallium nitride, gallium nitride or aluminum indium gallium nitride; the material of the nitride channel layer 12 can be group III nitrides such as gallium nitride; the nitride barrier layer The material of 13 can be group III nitrides such as aluminum gallium nitride; the buffer layer can play the role o...

Embodiment 3

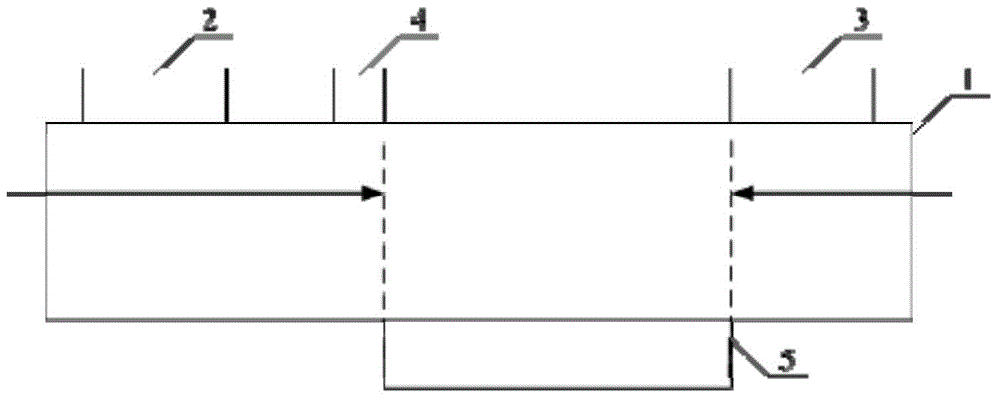

[0083] image 3 It is a cross-sectional view of the semiconductor device provided by Embodiment 3 of the present invention. like image 3 As shown, different from the semiconductor device provided in Embodiment 1 of the present invention, the heat conduction and / or voltage resistance layer 5 of the semiconductor device is located under the semiconductor layer 1 between the gate 4 and the drain 3 .

[0084] When a semiconductor device is in operation, the heat is mainly concentrated in the area between the gate and the drain. A thermally conductive and / or voltage-resistant layer is arranged under the semiconductor layer between the gate and the drain, and the area between the gate and the drain is formed by using the thermally conductive layer or the thermally conductive and voltage-resistant layer, as shown in the figure As shown in the range surrounded by the dotted line, most of the accumulated heat is dissipated effectively, uniformly and in a timely manner, making the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com