Electrolyte corrosion inhibitor, electrolyte for aluminum air cell and aluminum air cell

An aluminum-air battery and electrolyte technology, which is applied in the direction of fuel cell half-cells and primary battery-type half-cells, can solve the problems of not meeting environmental protection requirements, hindering the commercial application of aluminum-air batteries, and being expensive. Good economic and environmental benefits, reduced hydrogen evolution self-corrosion rate, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

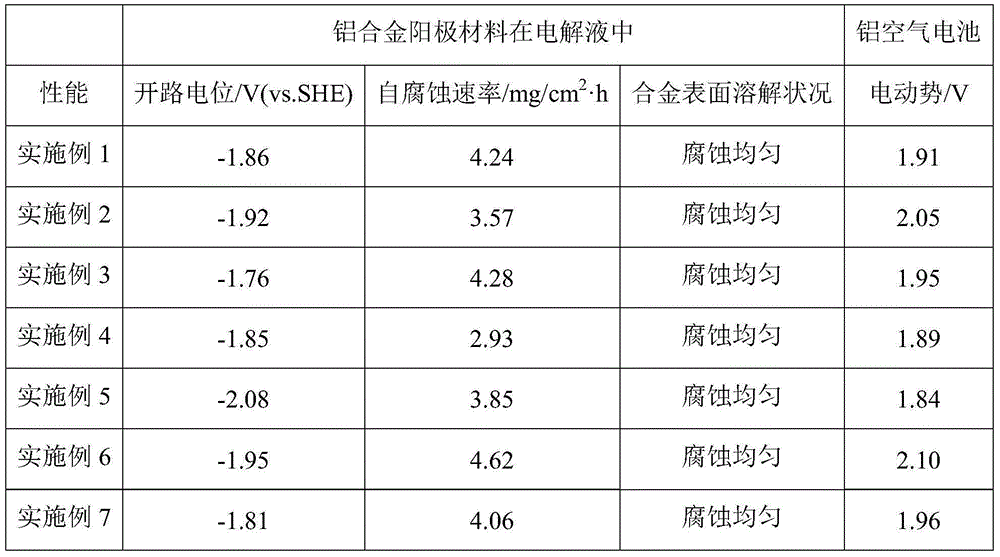

Examples

Embodiment 1

[0030] The electrolyte corrosion inhibitor of this embodiment is an ethanol solution of lavender essential oil, wherein the volume percentage of lavender essential oil is 45%.

[0031] The electrolyte solution for the aluminum-air battery of this embodiment contains components of the following concentrations: 3 mol / L of sodium hydroxide, 60 ppm (v / v) of the above electrolyte corrosion inhibitor, and the balance is distilled water. The preparation method of the electrolytic solution is as follows: take the sodium hydroxide of the formula quantity and add distilled water, stir the solution to make a sodium hydroxide solution; add the lavender essential oil corrosion inhibitor of the formula quantity into the sodium hydroxide solution, then add the remaining distilled water, stir Evenly, that is.

[0032] The aluminum-air battery of this embodiment includes an aluminum anode, an air cathode, and an electrolyte, and the electrolyte is the above-mentioned electrolyte for an aluminu...

Embodiment 2

[0037] The electrolyte corrosion inhibitor of this embodiment is an ethanol solution of lavender essential oil, wherein the volume percentage of lavender essential oil is 60%.

[0038] The electrolyte solution for the aluminum-air battery of this embodiment contains the following components at the following concentrations: 3 mol / L of sodium hydroxide, 80 ppm (v / v) of the above electrolyte corrosion inhibitor, and the balance is distilled water. The preparation method of the electrolytic solution is as follows: take the sodium hydroxide of the formula quantity and add distilled water, stir the solution to make a sodium hydroxide solution; add the lavender essential oil corrosion inhibitor of the formula quantity into the sodium hydroxide solution, then add the remaining distilled water, stir Evenly, that is.

[0039] The aluminum-air battery of this embodiment includes an aluminum anode, an air cathode, and an electrolyte, and the electrolyte is the above-mentioned electrolyte ...

Embodiment 3

[0047] The electrolyte corrosion inhibitor of this embodiment is an ethanol solution of lavender essential oil, wherein the volume percentage of lavender essential oil is 20%.

[0048] The electrolyte solution for the aluminum-air battery of this embodiment contains the following components at the following concentrations: 4 mol / L of sodium hydroxide, 20 ppm (v / v) of the above electrolyte corrosion inhibitor, and the balance is distilled water. The preparation method of the electrolytic solution is as follows: take the sodium hydroxide of the formula quantity and add distilled water, stir the solution to make a sodium hydroxide solution; add the lavender essential oil corrosion inhibitor of the formula quantity into the sodium hydroxide solution, then add the remaining distilled water, stir Evenly, that is.

[0049] The aluminum-air battery of this embodiment includes an aluminum anode, an air cathode, and an electrolyte, and the electrolyte is the above-mentioned electrolyte ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com